Abstract

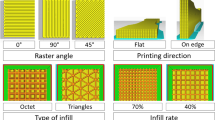

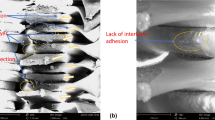

3D printing technologies offer numerous advantages and have attracted the attention of researchers recently. Yet, the most commonly preferred additive manufacturing system is the extrusion-based process that is called fused deposition modeling (FDM) as it is simple, low cost, and prone to customization. In this paper, the effects of the short-term aging of the additively manufactured PLA and ABS specimens were investigated experimentally. The test specimens were aged by keeping them at ambient temperatures of − 80, − 20, 60, 100 °C for 10, 20, and 30 days. Thermally aged specimens and the pristine specimens were forced to fracture with bending load at room temperature. Thus, the permanent effects of thermal aging of the specimens were investigated utilizing the load–deflection curve, plane-strain fracture toughness, and the morphologies of fracture surfaces. It was concluded that the printed PLA materials are more susceptible to the thermal aging than the ABS printed materials. The contraction and expansion of the fused polymer filaments affect directly the bonding strength between the adjacent layers. Therefore, plane-strain fracture characteristics of the FDM polymer materials exposed to thermal aging differ according to the filament orientation and the aging time.

Similar content being viewed by others

References

B.G. Bryden, I.R. Pashby, D.I. Wimpenny, and C. Adams, Laminated Steel Tooling in the Aerospace Industry, Mater. Des., 2000, 21(4), p 403–408

M. Attaran, The Rise of 3-D Printing: The Advantages of Additive Manufacturing Over Traditional Manufacturing, Bus. Horiz., 2017, 60(5), p 677–688. https://doi.org/10.1016/j.bushor.2017.05.011

A. Gebhardt, Understanding Additive Manufacturing, Carl Hanser Verlag GmbH & Co KG., Munich, 2011, p 173. ISBN: 978-3-446-42552-1

I. Gibson, D.W. Rosen, and B. Stucker, Additive Manufacturing Technologies Rapid Prototyping to Direct Digital Manufacturing, Assembly Autom., 2010. https://doi.org/10.1007/978-1-4419-1120-9

O. Diegel, Additive Manufacturing: An Overview, Comprehensive Materials Processing, Vol 10, S. Hashmi Ed., Newnes, London, 2014, p 3–18. https://doi.org/10.1016/B978-0-08-096532-1.01000-1

M. Vaezi, P. Drescher, and H. Seitz, Beamless Metal Additive Manufacturing, Materials, 2020, 13(4), p 922. https://doi.org/10.3390/ma13040922

Comparing AM Processes, http://apt.mit.edu/am-process-comparisons, Accessed on 27 Dec 2020

W.C. Lee, C.C. Wei, and S.C. Chung, Development of a Hybrid Rapid Prototyping System Using Low-Cost Fused Deposition Modeling and Five-Axis Machining, J. Mater. Process. Technol., 2014, 214(11), p 2366–2374. https://doi.org/10.1016/j.jmatprotec.2014.05.004

A. Jabbari and K. Abrinia, Developing Thixo-Extrusion Process for Additive Manufacturing of Metals in Semi-solid State, J. Manuf. Process., 2018, 35, p 664–671. https://doi.org/10.1016/j.jmapro.2018.08.031

Smart Additive Manufacturing, https://markforged.com, Accessed on 25 Dec 2020

Desktop Metal, Metal and Carbon Fiber 3D Printing, https://www.desktopmetal.com, Accessed on 25 Dec 2020

M. Harris, J. Potgieter, R. Archer, and K.M. Arif, Effect of Material and Process Specific Factors on the Strength of Printed Parts in Fused Filament Fabrication: A Review of Recent Developments, Materials, 2019. https://doi.org/10.3390/ma12101664

T.J. Gordelier, P.R. Thies, L. Turner, and L. Johanning, Optimising the FDM Additive Manufacturing Process to Achieve Maximum Tensile Strength: A State-of-the-Art Review, Rapid Prototyp. J., 2019. https://doi.org/10.1108/RPJ-07-2018-0183

D. Popescu, A. Zapciu, C. Amza, F. Baciu, and R. Marinescu, FDM Process Parameters Influence Over the Mechanical Properties of Polymer Specimens: A Review, Polym. Test., 2018, 69, p 157–166. https://doi.org/10.1016/j.polymertesting.2018.05.020

B. Huang and S. Singamneni, Raster Angle Mechanics in Fused Deposition Modelling, J. Compos. Mater., 2015, 49(3), p 363–383

O. Bamiduro and G. Owolabi, The Influence of Load Direction, Microstructure, Raster Orientation on the Quasi-static Response of Fused Deposition Modeling ABS, Rapid Prototyp. J., 2018, 3, p 462–472. https://doi.org/10.1108/RPJ-04-2018-0087

C.S. Davis, K.E. Hillgartner, S. Hoon, and J.E. Seppala, Mechanical Strength of Welding Zones Produced by Polymer Extrusion Additive Manufacturing, Addit. Manuf., 2017, 16, p 162–166. https://doi.org/10.1016/j.addma.2017.06.006

K. Abouzaid, D. Bassir, and A. Chouaf, Printability of Co-polyester Using Fused Deposition Modelling and Related Mechanical Performance, Eur. Polym. J., 2018, 108, p 262–273. https://doi.org/10.1016/j.eurpolymj.2018.08.034

N. Aliheidari, R. Tripuraneni, A. Ameli, and S. Nadimpalli, Fracture Resistance Measurement of Fused Deposition Modeling 3D Printed Polymers, Polym. Test., 2017, 60, p 94–101. https://doi.org/10.1016/j.polymertesting.2017.03.016

Y. Song, Y. Li, W. Song, K. Yee, K. Lee, and V.L. Tagarielli, Measurements of the Mechanical Response of Unidirectional 3D-Printed PLA, Mater. Des., 2017. https://doi.org/10.1016/j.matdes.2017.03.051

D. Popescu, F. Baciu, D. Vlăsceanu, C.M. Cotruţ, and R. Marinescu, Effects of Multiple Sterilizations and Natural Aging on the Mechanical Behavior of 3D-Printed ABS, Mech. Mater., 2020, 148, p 103423. https://doi.org/10.1016/j.mechmat.2020.103423

H. Kondo, T. Tanaka, T. Masuda, and A. Nakajima, Aging Effects in 16 Years on Mechanical Properties of Commercial Polymers (Technical Report), Pure Appl. Chem., 1992, 64(12), p 1945–1958. https://doi.org/10.1351/pac199264121945

Properties of the ABS and PLA Filaments, http://www.esun3d.net/DownLoad/, Accessed on 01 Jan 2021

Standard Test Methods for Plane-Strain Fracture Toughness and Strain Energy Release Rate of Plastic Material, http://www.dept.aoe.vt.edu/~aborgolt/aoe3054/manual/expt5/D5045.29646.pdf, Accessed on 01 Jan 2021

B.E. Tiganis, L.S. Burn, P. Davis, and A.J. Hill, Thermal Degradation of Acrylonitrile-Butadiene-Styrene (ABS) Blends, Polym. Degrad. Stab., 2002, 76, p 425–434. https://doi.org/10.1016/S0141-3910(02)00045-9

A. Moetazedian, A. Gleadall, X. Han, A. Ekinci, E. Mele, and V.V. Silberschmidt, Mechanical Performance of 3D Printed Polylactide during Degradation, Addit. Manuf., 2021, 38, p 101764. https://doi.org/10.1016/j.addma.2020.101764

J. Torres, O. Onwuzurike, A.J.W. McClung, and J.D. Ocampo, Influence of an Extreme Environment on the Tensile Mechanical Properties of a 3D Printed Thermoplastic Polymer. Mechanics of Additive and Advanced Manufacturing, Conference Proceedings of the Society for Experimental Mechanics Series, Vol 8, Springer, 2019. https://doi.org/10.1007/978-3-319-95083-9_12

K.R. Hart, R.M. Dunn, J.M. Sietins, C.M.H. Mock, M.E. Mackay, and E.D. Wetzel, Increased Fracture Toughness of Additively Manufactured Amorphous Thermoplastics via Thermal Annealing, Polymer, 2018, 144, p 192–204. https://doi.org/10.1016/j.polymer.2018.04.024

Acknowledgments

The authors wish to thank The Office of Scientific Research Projects of Alanya Alaaddin Keykubat University for funding this study under Contract No. 2020-02-06-MAP01.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Additive Manufacturing. The issue was organized by Dr. William Frazier, Pilgrim Consulting, LLC; Mr. Rick Russell, NASA; Dr. Yan Lu, NIST; Dr. Brandon D. Ribic, America Makes; and Caroline Vail, NSWC Carderock.

Rights and permissions

About this article

Cite this article

Darıcık, F., Delibaş, H., Canbolat, G. et al. Effects of Short-Term Thermal Aging on the Fracture Behavior of 3D-Printed Polymers. J. of Materi Eng and Perform 30, 8851–8858 (2021). https://doi.org/10.1007/s11665-021-06374-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06374-z