Abstract

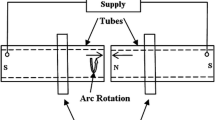

Dissimilar SAE 213 T11 and SAE 213 T91 boiler graded steel tubes are welded using magnetically impelled arc butt welding (MIAB) process, a hybrid welding process that combines the advantage of solid state and pressure welding technique. In this research, dissimilar tubes with an outer diameter of 44.5 mm and thickness of 4 mm with a length of 250 mm were joined by using the MIAB welding process. The microstructural behavior and changes of MIAB welded T11 and T91 tubes were analyzed at different zones of the butt-welded tubes using the metallurgical microscope and scanning electron microscope. Micro-Vickers hardness and potentiodynamic polarization test and radiographic testing were conducted. The hardness was taken at different zones along the transverse direction of the join. In the weld interface, the formation of a 2-3 µm martensitic structure leads to the hardness value of 281HV1, and at the base metal of T11 is 217HV1, T91 is 254HV1. The bead width at the welded region is approximately 10-12 µm with the narrow heat-affected zone. The metallurgical bonding between the T11 and T91 dissimilar tubes shows sound joint, which is confirmed with the radiography test.

Similar content being viewed by others

Reference

G. Dhivyasri, S.G. Rahul, P. Kavitha, S. Arungalai Vendan, K.A. Ramesh Kumar, L. Gao and A. Garg, Dynamic Control of Welding Current and Welding Time to Investigate Ultimate Tensile Strength of Miab Welded T11 Tubes, J. Manuf. Process., 2018, 32, p 564–581. https://doi.org/10.1016/j.jmapro.2018.03.031

S.A. Vendan, S. Manoharan, G. Buvanashekaran and C. Nagamani, Development of a MIAB Welding Module and Experimental Analysis of Rotational Behavior of Arc—Simulation of Electromagnetic Force Distribution during MIAB Welding of Steel Pipes Using Finite Element Analysis, Int. J. Adv. Manuf. Technol., 2009, 43(11–12), p 1144–1156. https://doi.org/10.1007/s00170-008-1793-x

G. Fj, The Magnet Arc Welding Process, Weld. Met. Fabr., 1974, 42, p 206–213.

R. Sivasankari, V. Balusamy, P.R. Venkateswaran, G. Buvanashekaran and K. Ganesh Kumar, Characterization of Magnetically Impelled Arc Butt Welded T11 Tubes for High Pressure Applications, Def. Technol., 2015, 11(3), p 244–254. https://doi.org/10.1016/j.dt.2015.03.005

D. Iordachescu, M. Iordachescu, B. Georgescu, R.M. Miranda, J. Ruiz-Hervias and J.L. Ocaña, Technological Windows for MIAB Welding of Tubes Featuring Original Longitudinal Magnetization System with Peripheral Solenoids, J. Mater. Process. Technol., 2010, 210(6–7), p 951–960. https://doi.org/10.1016/j.jmatprotec.2010.02.007

T. Sato, J. Katayama, S. Ioka and M. Otani, An Experimental Study of Rotational Behaviour of the Arc during Magnetically Impelled Arc Butt Welding, Weld. Int., 1991, 5(1), p 5–10. https://doi.org/10.1080/09507119109447814

J.-W. Kim and D.-H. Choi, A Study on the Numerical Analysis of Magnetic Flux Density by a Solenoid for Magnetically Impelled Arc Butt Welding, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf., 2003, 217(10), p 1401–1407. https://doi.org/10.1243/095440503322617171

V.S. Kachinskiy, V.G. Krivenko and V.Y. Ignatenko, Magnetically Impelled Arc Butt Welding of Hollow and Solid Parts, Weld. World, 2002, 46(7–8), p 49–56. https://doi.org/10.1007/BF03263390

J. Oñoro, Weld Metal Microstructure Analysis of 9–12% Cr Steels, Int. J. Press. Vessel. Pip., 2006, 83(7), p 540–545.

Y. Li, J. Wang, B. Zhou and T. Feng, XRD and TEM Analysis of Microstructure in the Welding Zone of 9Cr-1Mo-V-Nb Heat-Resisting Steel, Bull. Mater. Sci., 2002, 25(3), p 213–217.

S.A. Vendan, S. Manoharan and C. Nagamani, MIAB Welding of Alloy Steel Tubes in Pressure Parts: Metallurgical Characterization and Non Destructive Testing, J. Manuf. Process., 2012, 14(1), p 82–88. https://doi.org/10.1016/j.jmapro.2011.09.006

Y. Yi, P. Cho, A. Al Zaabi, Y. Addad and C. Jang, Potentiodynamic Polarization Behaviour of AISI Type 316 Stainless Steel in NaCl Solution, Corros. Sci., 2013, 74, p 92–97. https://doi.org/10.1016/j.corsci.2013.04.028

S. Al Saadi, Y. Yi, P. Cho, C. Jang and P. Beeley, Passivity Breakdown of 316L Stainless Steel during Potentiodynamic Polarization in NaCl Solution, Corros. Sci., 2016, 111, p 720–727. https://doi.org/10.1016/j.corsci.2016.06.011

A.H.V. Pavan, K.S.N. Vikrant, S. Nandi and K. Singh, Characterization of Fireside Corroded Sections of Boiler Tubes, Mater. Sci. Forum, 2012, 710, p 701–706.

A. Sharma, D. Kant Verma and S. Kumaran, Effect of Post Weld Heat Treatment on Microstructure and Mechanical Properties of Hot Wire GTA Welded Joints of SA213 T91 Steel, Mater. Today Proc., 2018, 5(2), p 8049–8056.

I.K. Razumov, Possible Mechanisms of the Formation of Bainitic Colonies, Phys. Solid State, 2019, 61(2), p 220–223.

C. Liu, Z. Zhao and S.D. Bhole, Lathlike Upper Bainite in a Silicon Steel, Mater. Sci. Eng. A, 2006, 434(1–2), p 289–293.

L. Falat, M. Svoboda, A. Výrostková, I. Petryshynets and M. Sopko, Microstructure and Creep Characteristics of Dissimilar T91/TP316H Martensitic/Austenitic Welded Joint with Ni-Based Weld Metal, Mater. Charact., 2012, 72, p 15–23.

S. Sirohi, C. Pandey and A. Goyal, Role of Heat-Treatment and Filler on Structure-Property Relationship of Dissimilar Welded Joint of P22 and F69 Steel, Fusion Eng. Des., 2020, 159, p 111935. https://doi.org/10.1016/j.fusengdes.2020.111935

J.G. Thakare, C. Pandey, M.M. Mahapatra and R.S. Mulik, An Assessment for Mechanical and Microstructure Behavior of Dissimilar Material Welded Joint between Nuclear Grade Martensitic P91 and Austenitic SS304 L Steel, J. Manuf. Process., 2019, 48, p 249–259.

D.D. Awale, A.R. Ballal and M.M. Thawre, Dissimilar Weld Joints of P91 and 316LN for Power Plants Applications-A Review, Mater. Today Proc., 2020, 28, p 2505–2510.

S. Orzolek, J. DuPont and J. Siefert, Microstructural Evolution of Dissimilar Metal Welds Involving Grade 91, Metall Mater. Trans. A Phys. Metall Mater. Sci., 2020, 51(5), p 2222–2238. https://doi.org/10.1007/s11661-020-05715-2

L.T. Nhung, P. Mai Khanh, N. Duc Thang and B.S. Hoang, Microstructures in Haz after Heat Treatment of Carbon Steel and Austenitic Stainless Steel Welds, Mater. Sci. Forum, 2020, 985, p 137–146.

L. Čiripová, L. Falat, V. Homolová, M. Džupon, R. Džunda and I. Dlouhý, The Effect of Electrolytic Hydrogenation on Mechanical Properties of T92 Steel Weldments under Different PWHT Conditions, Materials, 2020 https://doi.org/10.3390/ma13163653

J.P. Galler, J.N. DuPont, S.S. Babu and M. Subramanian, Microstructural Evolution of Graded Transition Joints, Metall. Mater. Trans. A Phys. Metall Mater. Sci., 2019, 50(5), p 2201–2217. https://doi.org/10.1007/s11661-019-05138-8

V.S. Kachinskiy, V.G. Krivenko, V.Y. Ignatenko and E.O. Paton, Magnetically Impelled ARC Butt Welding of Hollow and Solid Parts, Weld. World, 2002, 46(7–8), p 49–56. https://doi.org/10.1007/BF03263390

A. Tonti, D. Lega, A. Antonini, M. Romitelli and A. Alvino, (2015) Damage Characterization of an ASTM A 213 Grade 91 Tube after 116.000h of Service in a Reforming Plant, Int. J. Press. Vessel. Pip., 2015, 132–133, p 87–96.

S. Ramesh Kumar, B. Ravishankar and M. Vijay, “Prediction and Analysis of Magnetically Impelled Arc Butt Welded Dissimilar Metal, Mater. Today, 2019 https://doi.org/10.1016/j.matpr.2019.09.054

X. Gómez and J. Echeberría, Microstructure and Mechanical Properties of Low Alloy Steel T11–Austenitic Stainless Steel 347H Bimetallic Tubes, Mater. Sci. Technol., 2000, 16(2), p 187–193. https://doi.org/10.1179/026708300101507532

C. Pandey, J.G. Thakare, P. Tharaphadar, P. Kumar, A. Gupta and S. Sirohi, Characterization of the Soft Zone in Dissimilar Welds Joint of 2.25Cr-1Mo and Lean Duplex LDX2101 Steel, Fusion Eng. Des., 2021, 163, p 112147. https://doi.org/10.1016/j.fusengdes.2020.112147

N. Isasti, D. Jorge-Badiola, J. Alkorta and P. Uranga, Analysis of Complex Steel Microstructures by High-Resolution EBSD, JOM Miner. Metals Mater. Soc., 2016, 68(1), p 215–223. https://doi.org/10.1007/s11837-015-1677-0

R.H. Larn and J.R. Yang, The Effect of Compressive Deformation of Austenite on the Bainitic Ferrite Transformation in Fe-Mn-Si-C Steels, Mater. Sci. Eng. A, 2000, 278(1–2), p 278–291.

F.G. Caballero, H. Roelofs, S. Hasler, C. Capdevila, J. Chao, J. Cornide and C. Garcia-Mateo, Influence of Bainite Morphology on Impact Toughness of Continuously Cooled Cementite Free Bainitic Steels, Mater. Sci. Technol., 2012 https://doi.org/10.1179/1743284710Y.0000000047

B. Josefsson and H.-O. Andrén, Microstructure of Granular Bainite, Le J. Phys. Colloq., 1988, 49, p C6-293-C6-298. https://doi.org/10.1051/jphyscol:1988651

Q.S. Wang, W.Q. Wang and Z.M. Shi, Study on Microstructure of Directional Solidified T91 Steel, IOP Conf. Ser. Earth Environ. Sci, 2018, 113, p 12146.

D.R. BUSH, “An Introduction to the 9Cr-1Mo-V Alloys,” 2001, p 1–8

K. Ramchandran, M. Arun, V. Ganesan and M. Sivaraja, Correlation between Ultrasonic Parameters, Mechanical Properties and Microstructures of Mod T91 Ferritic-Martensitic Steel (PFBR), Int. J. Mech. Eng. Res., 2015, 5(1), p 102–108.

A.B. Zala, N.I. Jamnapara, V.J. Badheka, S. Sam and M. Ranjan, Effect of Aluminide Coatings on Penetration and Microstructure of TIG Welded 9Cr-1Mo Steel for Fusion Blanket Applications, Fusion Eng. Des., 2019, 144, p 172–179. https://doi.org/10.1016/j.fusengdes.2019.04.080

Y. Yu, S. Shironita, K. Souma and M. Umeda, Effect of Chromium Content on the Corrosion Resistance of Ferritic Stainless Steels in Sulfuric Acid Solution, Heliyon, 2018, 4(11), p e00958.

A. Van Bennekom, L.M. Matthews, J.N. Tarboton, The Effect of Martensite Content on the Corrosion and Mechanical Properties of Dual-Phase 12 per Cent Cr Steels, Proc. 1st Int. Chromium Steel Alloy. Congr., (Cape Town), 1992, 2, p 157–163, https://www.pyrometallurgy.co.za/InfaconVI/2157-VanBennekom.pdf. Accessed 3 May 2021

T. Bellezze, G. Giuliani and G. Roventi, Study of Stainless Steels Corrosion in a Strong Acid Mixture. Part 1: Cyclic Potentiodynamic Polarization Curves Examined by Means of an Analytical Method, Corros. Sci., 2018, 130, p 113–125. https://doi.org/10.1016/j.corsci.2017.10.012

T. Ohtsuka and T. Komatsu, Enhancement of Electric Conductivity of the Rust Layer by Adsorption of Water, Corros. Sci., 2005, 47(10), p 2571–2577. https://doi.org/10.1016/j.corsci.2004.10.010

Acknowledgments

This work was funded by ‘‘Department of Science and Technology, Government of India through SERB under the ECR scheme” grant number ECR/2017/003021. The author would also thank the SASTRA Deemed University for their assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ramesh Kumar, S., SreeArravind, M. Assessment of Magnetically Impelled Arc Butt Welded Dissimilar Boiler Graded Steel Tubes: SAE213 T11 and SAE213 T91. J. of Materi Eng and Perform 31, 1846–1856 (2022). https://doi.org/10.1007/s11665-021-06343-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06343-6