Abstract

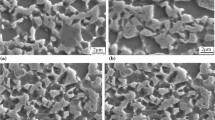

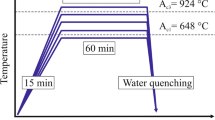

This work investigated the microstructure, mechanical properties and corrosion behavior of dual-phase (DP) steel after different intercritical quenching treatment and compared the results with commercial AH32 steel. The results indicate that the microstructure of all tested DP steels was composed of lath martensite and polygonal ferrite. As the temperature increased from 750 to 850 °C, the martensite lath became slender, whereas martensite volume fraction (Vm) increased from 53 to 71%. The change in the morphology and content of martensite not only led to an increase in hardness and yield strength, but also to a decrease in the plasticity and impact toughness, which was consistent with the mixture law. However, the ultimate tensile strength did not increase but declined, which was an unusual behavior. It was related to the micro-void coalescence fracture mechanism caused by the ferrite/martensite interface decohesion. Moreover, the increasing temperature led to the enhanced galvanic effect between ferrite and martensite, accelerating the corrosion rate of DP steels in a 3.5% NaCl solution. A comparison of all results in our work indicates that DP750 steel with 53% martensite had excellent comprehensive properties.

Similar content being viewed by others

References

R. Shukla, S.K. Ghosh, D. Chakrabarti, and S. Chatterjee, Microstructure, Texture, Property Relationship in Thermo-Mechanically Processed Ultra-Low Carbon Microalloyed Steel for Pipeline Application, Mater. Sci. Eng., A, 2013, 587, p 201–208

L. Qian, Q. Zhou, F. Zhang, J. Meng, M. Zhang, and Y. Tian, Microstructure and Mechanical Properties of a Low Carbon Carbide-Free Bainitic Steel co-Alloyed with Al and Si, Mater. Design, 2012, 39, p 264–268

P. Mallick, N.K. Tewary, S.K. Ghosh, and P.P. Chattopadhyay, Microstructure-Tensile Property Correlation in 304 Stainless Steel After Cold Deformation and Austenite Reversion, Mater. Sci. Eng. A, 2017, 707, p 488–500

M. Ko, B. Ingham, N. Laycock, and D.E. Williamsde, In Situ Synchrotron X-Ray Diffraction Study of the Effect of Microstructure And Boundary Layer Conditions on CO2 Corrosion of Pipeline Steels, Corros. Sci., 2015, 90, p 192–201

D. Kong, X. Ni, C. Dong, L. Zhang, C. Man, J. Yao, K. Xiao, and X. Li, Heat Treatment Effect on the Microstructure and Corrosion Behavior of 316L Stainless Steel Fabricated by Selective Laser Melting for Proton Exchange Membrane Fuel Cells, Electrochim. Acta, 2018, 276, p 293–303

Y. Kang, Q. Han, X. Zhao, and M. Cai, Influence of Nanoparticle Reinforcements on the Strengthening Mechanisms of an Ultrafine-Grained Dual Phase Steel Containing Titanium, Mater. Design, 2013, 44, p 331–339

C. Zheng and D. Raabe, Interaction Between Recrystallization and Phase Transformation During Intercritical Annealing in a Cold-Rolled Dual-Phase Steel: A Cellular Automaton Model, Acta Mater., 2013, 61, p 5504–5517

K. Park, M. Nishiyama, N. Nakada, T. Tsuchiyama, and S. Takaki, Effect of the Martensite Distribution on the Strain Hardening and Ductile Fracture Behaviors in Dual-Phase Steel, Mater. Sci. Eng. A, 2014, 604, p 135–141

M. Calcagnotto, Y. Adachi, D. Ponge, and D. Raabe, Deformation and Fracture Mechanisms in Fine-and Ultrafine-Grained Ferrite/Martensite Dual-Phase Steels and the Effect of Aging, Acta Mater., 2011, 59, p 658–670

G. Song, T. Vystavel, N. Pers, J. Hosson, and W. Sloof, Relation Between Microstructure and Adhesion of Hot DIP Galvanized Zinc Coatings on Dual Phase Steel, Acta Mater., 2012, 60, p 2973–2981

M. Shahzad, Q. Tayyaba, T. Manzoor, T.Subhani Rafi ud-din, and A. Qureshi, The effects of Martensite Morphology on Mechanical Properties, Corrosion Behavior and Hydrogen Assisted Cracking in A516 Grade Steel, Mater. Res. Express, 2018, 5, p 016516

E. Erişir and O.G. Bilir, Effect of Intercritical Annealing Temperature on Phase Transformations in Medium Carbon Dual Phase Steels, J. Mate. Eng. Perform., 2014, 23, p 1055–1061

A. Ghaheri, A. Shafyei, and M. Honarmand, Effects of Inter-Critical Temperatures on Martensite Morphology, Volume Fraction and Mechanical Properties of Dual-Phase Steels Obtained from Direct and Continuous Annealing Cycles, Mater. Design, 2014, 1980–2015(62), p 305–319

S. Banadkouki and E. Fereiduni, Effect of Prior Austenite Carbon Partitioning on Martensite Hardening Variation in a Low Alloy Ferrite–Martensite Dual Phase Steel, Mater. Sci. Eng. A, 2014, 619, p 129–136

M. Asadi, B.C. Cooman, and H. Palkowski, Influence of Martensite Volume Fraction and Cooling Rate on the Properties of Thermomechanically Processed Dual Phase Steel, Mater. Sci. Eng. A, 2012, 538, p 42–52

W. Woo, V.T. Em, E.Y. Kim, S.H. Han, Y.S. Han, and S.H. Choi, Stress–Strain Relationship Between Ferrite and Martensite in a Dual-Phase Steel Studied by In Situ Neutron Diffraction and Crystal Plasticity Theories, Acta Mater., 2012, 60, p 6972–6981

H. Ghassemi-Armaki, R. Maaß, S.P. Bhat, S. Sriram, J.R. Greer, and K.S. Kumar, Deformation Response of Ferrite and Martensite in a Dual-Phase Steel, Acta Mater., 2014, 62, p 197–211

P. Movahed, S. Kolahgar, S. Marashi, M. Pouranvari, and N. Parvin, The Effect of Intercritical Heat Treatment Temperature on the Tensile Properties and Work Hardening Behavior of Ferrite–Martensite Dual Phase Steel Sheets, Mater. Sci. Eng. A, 2009, 518, p 1–6

Steel and Steel Products-Location and Preparation of Samples and Test Pieces for Mechanical Testing, GB/T 2975-2018, Standards Press of China, 2018.

Standard Test Methods for Tension Testing of Metallic Materials, ASTM E8/E8M-16a, ASTM International, 2016.

Metallic materials-Charpy pendulum impact test method, Standards Press of China GB/T 229-2007, 2007.

H. Farivar, S. Richter, M. Hans, A. Schwedt, U. Prahl, and W. Bleck, Experimental Quantification of Carbon Gradients in Martensite and Its Multi-Scale Effects in a DP Steel, Mater. Sci. Eng. A, 2018, 718, p 250–259

L.D. Barlow and M.D. Toit, Effect of Austenitizing Heat Treatment on the Microstructure and Hardness of Martensitic Stainless Steel AISI, 420, J. Mate. Eng. Perform., 2012, 21, p 1327–1336

Y. Mazaheria and G. Kalashami, High Strength-Elongation Balance in Ultrafine Grained Ferrite-Martensite Dual Phase Steels Developed by Thermomechanical Processing, Mater. Sci. Eng. A, 2019, 761, p 138021

J. Zhang, H. Di, Y. Deng, and R. Misra, Effect of Martensite Morphology and Volume Fraction on Strain Hardening and Fracture Behavior of Martensite–Ferrite Dual Phase Steel, Mater. Sci. Eng. A, 2015, 627, p 230–240

A.P. Pierman, O. Bouaziz, T. Pardoen, P. Jacques, and L. Brassart, The Influence of Microstructure and Composition on the Plastic Behaviour of Dual-Phase Steels, Acta Mater., 2014, 73, p 298–311

N. Farabi, D.L. Chen, and Y. Zhou, Microstructure and Mechanical Properties of Laser Welded Dissimilar DP600/DP980 Dual-Phase Steel Joints, J. Alloy. Compd., 2011, 509, p 982–989

E. Ahmad, T. Manzoor, K. Ali, and J. Akhter, Effect of Microvoid Formation on the Tensile Properties of Dual-Phase Steel, J. Mate. Eng. Perform., 2000, 9, p 306–310

Standard Practice for Calculation of Corrosion Rates and Related Information from Electrochemical Measurements, ASTM G102–04, ASTM International, 2004.

T. Baldhoff and A. Marshall, Characterization of Surface Films Formed on Aluminum During Mass-Transfer Limited Anodic Dissolution in Phosphoric Acid, J. Electrochem. Soc., 2017, 164, p 46–53

C.N. Cao, Principles of Electrochemistry of Corrosion, 3rd ed., Chemical Industry Press, Beijing, 2008, p 109–112

Acknowledgments

This work was supported by the PhD early development program of Liaocheng University (Grant No. 318051735).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hao, X., Zhao, X., Huang, B. et al. Influence of Intercritical Quenching Temperature on Microstructure, Mechanical Properties and Corrosion Resistance of Dual-Phase Steel. J. of Materi Eng and Perform 29, 4446–4456 (2020). https://doi.org/10.1007/s11665-020-04928-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04928-1