Abstract

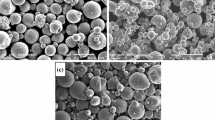

This study reports on the microstructure, phase identification and hardness property of the LENS-manufactured binary Ti-Al alloy which was achieved via laser in situ alloying. The in situ alloying method, using laser beam as an energy source, indicated that it is possible to achieve a binary gamma phase microstructure from elemental powders of Ti and Al. The as-produced sample, however, was characterized of having different microstructure at the top, middle and bottom regions. The middle and top layers had similar hardness which was lower than that of the bottom region. The as heat-treated sample was characterized of lamellar grain microstructure at the top and just grains at the bottom and the middle. The observed grains were different in size, phase and hardness. This study indicated that in addition to the pores and the precipitation of α2 phase or aluminum segregation on the grain boundary veins intermetallics lead to severe cracking. Overall, the hardness values of the as-produced and heat-treated samples were similar, and due to extensive cracking, it was inferred that both samples will lack ductility.

Similar content being viewed by others

References

F. Appel, M. Oehring, and J.D.H. Paul, A Novel In Situ Composite Structure in TiAl Alloys, Mater. Sci. Eng. A, 2008, 493, p 232–236

A. Clemens, A. Bartels, S. Bystrzanowski, H. Chladil, H. Leitner, G. Dehm, R. Gerling, and F.P. Schimansky, Grain Refinement in γ-TiAl Based Alloys by Solid State Phase Transformations, Intermetallics, 2006, 14, p 1380–1385

A. Rostamian and A. Jacot, A Numerical Model for the Description of the Lamellar and Massive Phase Transformation in TiAl Alloys, Intermetallics, 2008, 16, p 1227–1236

F. Appel, H. Clemens, and F.D. Fischer, Modeling Concepts for Intermetallic Titanium Aluminides, Prog. Mater Sci., 2016, 81, p 55–124

G. Wang and M. Dahms, Synthesizing Gamma-TiAl Alloys by Reactive Powder Processing, JOM, 1993, 45, p 52–56 (in English)

N.A. Nochovnaya, P.V. Panin, A.S. Kochetkov, and K.A. Bokov, Modern Refractory Alloys Based on Titanium Gamma-Aluminide: Prospects of Development and Application, Met. Sci. Heat Treat., 2014, 56(8), p 23–27

H. Clemens and S. Mayer, Design, Processing, Microstructure, Properties, and Applications of Advanced Intermetallic TiAl Alloys, Adv. Eng. Mater., 2013, 15(4), p 191–215

J.D.K. Rivard, A.S. Sabau, C.A. Blue, D.C. Harper, and J.O. Kiggans, Modeling and Processing of Liquid-Phase-Sintering γ-TiAl During High-density Infrared Processsing, Metall. Mater. Trans. A, 2006, 37A, p 1289–1299

M. Todai, T. Nakano, T. Liu, H.Y. Yasuda, K. Hagihara, K. Cho, M. Ueda, and M. Takeyama, Effect of Building Direction on the Microstructure and Tensile Properties of Ti-48Al-2Cr-2Nb Alloy Additively Manufactured by Electron Beam Melting, Addit. Manuf., 2017, 13, p 61–70

R. Gerling, E. Aust, W. Limberg, M. Pfuff, and F.P. Schimansky, Metal Injection Moulding of gamma Titanium Aluminide Alloy Powder, Mater. Sci. Eng. A, 2006, 423, p 262–268

A. Dehghan-Manshadi, D. StJohn, M. Dargusch, Y. Chen, J.F. Sun, and M. Qian, Metal Injection Moulding of Non-spherical Titanium Powders: Processing, Microstructure and Mechanical Properties, J. Manuf. Process., 2018, 31, p 416–423

R. Gerling and F.P. Schimansky, Prospects for Metal Injection Moulding Using a Gamma Titanium Based Alloy Powder, Mater. Sci. Eng. A, 2002, 329-331, p 45–49

A. Dehghan-Manshadi, M.J. Bermingham, M.S. Dargusch, D.H. StJohn, and M. Qian, Metal Injection Moulding of Titanium and Titanium Alloys: Challenges and Recent Development, Powder Technol., 2017, 319, p 289–301

L.E. Murr, Metallurgy of Additive Manufacturing: Examples from Electron Beam Melting, Addit. Manuf., 2015, 5, p 40–53

M. Galati and L. Iuliano, A Literature Review of Powder-Based Electron Beam Melting Focusing on Numerical Simulation, Addit. Manuf., 2018, 19, p 1–20

P.K. Gokuldoss, S. Kolla, and J. Eckert, Additive Manufacturing Processes: Selective Laser Melting, Electron Beam Melting and Binder Jetting-Selection Guidelines, Materials, 2017, 10(672), p 1–12

M. Tlotleng, B. Masina, and S. Pityana, Characteristics of Laser In Situ Alloyed Titanium Aluminides Coatings, Procedia Manuf., 2017, 7, p 39–45

A.N.D. Gasper, S. Catchpole-Smith, and A.T. Clare, In Situ Synthesis of Titanium Aluminides by Direct Metal Deposition, J. Mater. Process. Technol., 2017, 239, p 230–239

M. Thomas, T. Malot, and P. Aubry, Laser Metal Deposition of the Intermetallic TiAl Alloy, Metall. Mater. Trans. A, 2017, 48A, p 3143–3157

R.M. Imaev, V.M. Imaev, and T.G. Khismatullin, Refining of the Microstructure of Cast Intermetallic Alloy Ti-43% Al-X (Nb, Mo, B) with the Help of Heat Treatment, Met. Sci. Heat Treat., 2006, 48(1-2), p 81–84

Y.H. Wang, J.P. Lin, Y.H. He, X. Lu, Y.L. Wang, and G.L. Chen, Microstructure and Mechanical Properties of High Nb Containing TiAl Alloys by Reactive Hot Pressing, J. Alloys Compd., 2008, 461, p 367–372

A.R.C. Sharman, J.I. Hughes, and K. Ridgway, Characterisation of Titanium Aluminide Components Manufactured by Laser Metal Deposition, Intermetallics, 2018, 93, p 89–92

J. Lapin, Z. Gabalcova, and O. Bajana, The Effect of Microstructure on the Mechanical Properties of Directionally Solidified Intermetallic Ti-46Al-8Nb Alloy, Kovové Materiály, 2009, 47, p 159–167 (in English)

Y. Guangyu, J. Wenpeng, Z. Pei, J. Liang, L. Nan, W. Jian, and T. Huiping, Microstructure of As-Fabricated and Post Heat Treated Ti-47Al-2Nb-2Cr Alloy Produced by Selective Electron Beam Melting (SEBM), Rare Met. Mater. Eng., 2016, 45(7), p 1683–1686

I. Shishkovsky, F. Missemer, and I. Smurov, Direct Metal Deposition of Functional Graded Structures in Ti-Al System, Phys. Procedia, 2012, 39, p 382–391

K. Kothari, R. Radhakrishnan, N.M. Wereley, and T.S. Sudarshan, Microstructure and Mechanical Properties of Consolidated Gamma Titanium Aluminides, Powder Metall., 2007, 50(1), p 21–27

T. Voisin, J.-P. Monchoux, M. Perrut, and A. Couret, Obtained of a Fine Near-Lamellar Microstructure in TiAl Alloys by Spark Plasma Sintering, Intermetallics, 2016, 71, p 88–97

C. Mercer and W.O. Soboyejo, Hall–Patch Relationship in Gamma Titanium Aluminides, Scr. Mater., 1996, 35(1), p 17–22

Acknowledgments

The author would like to acknowledge the financial support that was received from both The National Research Foundation and The Council for Scientific and Industrial Research. The following grants supported this research: National Research Foundation Thuthuka (Grant No. BM_TTK170905261706), CSIR Young Researcher Establishment Funds (YREF212) and CSIR Parliamentary Grant (LMIRDPP07030).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tlotleng, M. Microstructural Properties of Heat-Treated LENS In Situ Additively Manufactured Titanium Aluminide. J. of Materi Eng and Perform 28, 701–708 (2019). https://doi.org/10.1007/s11665-018-3789-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3789-5