Abstract

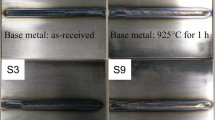

A gamma prime (γ′) precipitation (~35% in volume)-hardened powder metallurgy (P/M) superalloy FGH96 was welded using inertia friction welding (IFW). The microstructure and γ′ distributions in the joints in two conditions, hot isostatic pressed state and solution-treated and aged state, were characterized. The recrystallization of grains, the dissolution and re-precipitation of γ′ in the joints were discussed in terms of the temperature evolutions which were calculated by finite element model analysis. Regardless of the initial states, fully recrystallized fine grain structure formed at welded zone. Meanwhile, very fine γ′ precipitations were re-precipitated at the welded zone. These recrystallized grain structure and fine re-precipitated γ′ resulted in increasing hardness of IFW joint while making the hardness dependent on the microstructure and γ′ precipitation.

Similar content being viewed by others

References

H.Y. Li, J.F. Sun, M.C. Hardy, H.E. Evans, S.J. Williams, T.J.A. Doel, and P. Bowen, Effects of Microstructure on High Temperature Dwell Fatigue Crack Growth in a Coarse Grain PM Nickel Based Superalloy, Acta Mater., 2015, 90, p 355–369

L. Zheng, M. Zhang, and J. Dong, Oxidation Behavior and Mechanism of Powder Metallurgy Rene95 Nickel Based Superalloy Between 800 and 1000 °C, Appl. Surf. Sci., 2010, 256(24), p 7510–7515

S.G. Tian, Y. Liu, X.M. Zhou, Z.G. Zhao, X.Y. Bao, and W.X. Wang, Creep Behaviors of FGH95 Powder Ni-Base Superalloy, Chin. J. Aeronaut., 2009, 22(4), p 444–448

W.P. Yang, G.Q. Liu, K. Wu, and B.F. Hu, Influence of Sub-solvus Solution Heat Treatment on Morphological Instability in a New Ni-Cr-Co-Based Powder Metallurgy Superalloy, J. Alloys Compd., 2014, 582, p 515–521

J. Xie, S. Tian, L.J. Shang, and X. Zhou, Creep Behaviors and Role of Dislocation Network in a Powder Metallurgy Ni-Based Superalloy During Medium-Temperature, Mater. Sci. Eng. A, 2014, 606, p 304–312

C.J. Wu, Y. Tao, and J. Jia, Microstructure and Properties of an Advanced Nickel-Base PM Superalloy, J. Iron Steel Res., 2014, 21(12), p 1152–1157

M. Zhang, F. Li, Z. Yuan, J. Li, and S. Wang, Effect of Heat Treatment on the Micro-indentation Behavior of Powder Metallurgy Nickel Based Superalloy FGH96, Mater. Des., 2013, 49, p 705–715

Y.L. Gu, C.H. Tao, and Y.H. He, Thermomechanical Fatigue Behavior of Powder Metallurgical Nickel Based Superalloy FGH96, J. Iron Steel Res., 2010, 16(6), p 74–79

M. Preuss, J.W.L. Pang, P.J. Withers, and G.J. Baxter, Inertia Welding Nickel-Based Superalloy. I. Metallurgical Characterization, Metall. Mater. Trans. A, 2002, 33A(10), p 3215–3225

M. Preuss, J.W.L. Pang, P.J. Withers, and G.J. Baxter, Inertia Welding Nickel-Based Superalloy: Part II. Residual Stress Characterization, Metall. Mater. Trans. A, 2002, 33(10), p 3227–3234

M.L. Grant, P.J. Withers, G. Baxter, and M. Preuss, Thermal Relaxation of Residual Stresses in Nickel-Based Superalloy Inertia Friction Welds, Metall. Mater. Trans. A, 2011, 42A, p 2301–2311

M. Maalekian, E. Kozeschnik, H.P. Brantner, and H. Cerjak, Comparative Analysis of Heat Generation in Friction Welding of Steel Bars, Acta Mater., 2008, 56(12), p 2843–2855

J.S. Tiley, D.W. Mahaffey, T. Alam, T. Rojhirunsakool, O. Senkov, T. Parthasarthy, and R. Banerjee, Strengthening Mechanisms in an Inertia Friction Welded Nickel-Base Superalloy, Mater. Sci. Eng. A, 2016, 662, p 26–35

M. Preuss, P.J. Withers, and G.J. Baxter, A Comparison of Inertia Friction Welds in Three Nickel Base Superalloys, Mater. Sci. Eng. A, 2006, 437(1), p 38–45

O. Iracheta, C.J. Bennett, and W. Sun, Characterization of Material Property Variation Across an Inertia Friction Welded CrMoV Steel Component Using the Inverse Analysis of Nanoindentation Data, Int. J. Mech. Sci., 2016, 107, p 253–263

Z. Yuanzhi, Y. Zhimin, L. Dongmei, L. Junchao, and Z. Xiang, Microstructure and Property of Ni76Cr19AlTi Side in Inertia Friction Weld Joint of the Superalloy Ni76Cr19AlTi and the Martensite Stainless Steel 4Cr10Si2Mo, ISIJ Int., 2010, 50(11), p 1666–1670

Z. Yuanzhi, Z. Zhe, X. Zhidong, Y. Zhimin, W. Zhifang, and Y. Wenqing, Microstructural Evolution in 4Cr10Si2Mo at the 4Cr10Si2Mo/Nimomic 80A Weld Joint by Inertia Friction Welding, J. Alloys Compd., 2009, 476, p 341–347

F. Daus, H.Y. Li, G. Baxter, S. Bray, and P. Bowen, Mechanical and Microstructural Assessments of RR1000 to IN718 Inertia Welds: Effects of Welding Parameters, Mater. Sci. Technol., 2007, 23(12), p 1424–1432

L. D’Alvise, E. Massoni, and S.J. Walloe, Finite Element Modelling of the Inertia Friction Welding Process Between Dissimilar Materials, J. Mater. Process. Technol., 2002, 125-126, p 387–391

B. Grant, M. Preuss, P.J. Withers, G. Baxter, and M. Rowlson, Finite Element Process Modelling of Inertia Friction Welding Advanced Nickel-Based Superalloy, Mater. Sci. Eng. A, 2009, 513-514(C), p 366–375

M. Kessler, S. Suenger, M. Haubold, and M.F. Zaeh, Modeling of Upset and Torsional Moment During Inertia Friction Welding, J. Mater. Process. Technol., 2016, 227, p 34–40

L. Wang, M. Preuss, P.J. Withers, G. Baxter, and P. Wilson, Energy-Input-Based Finite-Element Process Modeling of Inertia Welding, Metall. Mater. Trans. B, 2005, 36(4), p 513–523

R.P. Turner, D. Howe, B. Thota, R.M. Ward, H.C. Basoalto, and J.W. Brooks, Calculating the Energy Required to Undergo the Conditioning Phase of a Titanium Alloy Inertia Friction Weld, J. Manuf. Process., 2016, 24, p 186–194

C. Liu, H.Y. Zhu, and C.L. Dong, Internal Residual Stress Measurement on Inertia Friction Welding of Nickel-Based Superalloy, Sci. Technol. Weld. Join., 2014, 19(5), p 408–415

L.F. Nie, L.W. Zhang, Z. Zhu, and W. Xu, Microstructure Evolution Modeling of FGH96 Superalloy During Inertia Friction Welding Process, Finite Elem. Anal. Des., 2014, 80, p 63–68

D.W. Mahaffey, O.N. Senkov, R. Shivpuri, and S.L. Semiatin, Effect of Process Variables on the Inertia Friction Welding of Superalloys LSHR and Mar-M247, Metall. Mater. Trans. A, 2016, 47(8), p 3981–4000

C. Zhang, L. Zhang, M. Li, W. Shen, and S. Gu, Effects of Microstructure and Gamma’ Distribution on the Hot Deformation Behavior for a Powder Metallurgy Superalloy FGH96, J. Mater. Res., 2014, 29(23), p 2799–2808

Z.W. Huang, H.Y. Li, M. Preuss, M. Karadge, P. Bowen, S. Bray, and G. Baxter, Inertia Friction Welding Dissimilar Nickel-Based Superalloys Alloy 720Li to IN718, Metall. Mater. Trans. A, 2007, 38(7), p 1608–1620

Y.Q. Ning, M.W. Fu, and W. Yao, Recrystallization of the Hot Isostatic Pressed Nickel-Base Superalloy FGH4096. II: Characterization and Application, Mater. Sci. Eng. A, 2012, 539, p 101–106

Y.Q. Ning, Z.K. Yao, M.W. Fu, and H.Z. Guo, Recrystallization of the Hot Isostatic Pressed Nickel-Base Superalloy FGH4096: I. Microstructure and Mechanism, Mater. Sci. Eng. A, 2011, 528(28), p 8065–8070

C.L. Qiu, M.M. Attallah, X.H. Wu, and P. Andrews, Influence of Hot Isostatic Pressing Temperature on Microstructure and Tensile Properties of a Nickel-Based Superalloy Powder, Mater. Sci. Eng. A, 2013, 564, p 176–185

Y.Q. Chen, E. Francis, J. Robson, M. Preuss, and S.J. Haigh, Compositional Variations for Small-Scale Gamma Prime (γ’) Precipitates Formed at Different Cooling Rates in an Advanced Ni-Based Superalloy, Acta Mater., 2015, 85, p 199–206

Y.Q. Chen, T.J.A. Slater, E.A. Lewis, E.M. Francis, M.G. Burke, M. Preuss, and S.J. Haigh, Measurement of Size-Dependent Composition Variations for Gamma Prime (‘) Precipitates in an Advanced Nickel-Based Superalloy, Ultramicroscopy, 2014, 144, p 1–8

Z.W. Huang, H.Y. Li, G. Baxter, S. Bray, and P. Bowen, Electron Microscopy Characterization of the Weld Line Zones of an Inertia Friction Welded Superalloy, J. Mater. Process. Technol., 2011, 211(12), p 1927–1936

Acknowledgments

This work was supported by the Fundamental Research Funds for the Central Universities of China and the open fund of the Key Laboratory for Metallurgical Equipment and Control of Ministry of Education in WUHAN University of Science and Technology, China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, C., Shen, W., Zhang, L. et al. The Microstructure and Gamma Prime Distributions in Inertia Friction Welded Joint of P/M Superalloy FGH96. J. of Materi Eng and Perform 26, 1581–1588 (2017). https://doi.org/10.1007/s11665-017-2601-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2601-2