Abstract

In this study, high-strength AA7075 alloy samples were cryogenically forged after annealing and then subjected to solution and aging treatments. The cryogenically forged 7075-T73 alloy samples displayed equiaxed fine grains associated with abundant fine precipitates in their matrix. Compared with conventional 7075-T73 alloy samples, the cryogenically forged samples exhibited an 8-12% reduction in tensile strength and an increased fatigue strength and higher corrosion resistance. The fatigue strength measured at 107 cycles was 225 MPa in the bare samples; the strength was increased to 250 MPa in the cryogenically forged samples. The effect of anodization on the corrosion resistance of the bare samples was improved from (E corr) −0.80 to −0.61 V.

Similar content being viewed by others

References

Y.S. Huang, T.S. Shih, and J.H. Chou, Electrochemical Behavior of Anodized AA7075-T73 Alloys Affected by Matrix Structures, Appl. Surf. Sci., 2013, 283, p 249–257

K. Golpala Krishna, K. Sivaprasad, K. Venkateswarlu, and K.C. Hari Kumar, Microstructural Evolution and Aging Behavior of Cryorolled Al-4Zn-2Mg Alloy, Mater. Sci. Eng. A Struct., 2012, 535, p 129–135

P. Das, R. Jayaganthan, and I.V. Singh, Tensile and Impact-Toughness Behaviour of Cryorolled Al 7075 Alloy, Mater. Des., 2011, 32, p 1298–1305

S.K. Panigrahi and R. Jayaganthan, Development of Ultrafine Grained High Strength Age Hardenable Al 7075 Alloy by Cryorolling, Mater. Des., 2011, 32, p 3150–3160

S.K. Panigrahi and R. Jayaganthan, Effect of Ageing on Microstructure and Mechanical Properties of Bulk, Cryorolled, and Room Temperature Rolled Al 7075 Alloy, J. Alloy Compd., 2011, 509, p 9609–9616

J. Yin, J. Lu, H. Ma, and P. Zhang, Nanostructural Formation of Fine Grained Aluminum Alloy by Severe Plastic Deformation at Cryogenic Temperature, J. Mater. Sci., 2004, 39, p 2851–2854

T.S. Shih, T.H. Lee, and Y.J. Jhou, The Effects of Anodization Treatment on the Microstructure and Fatigue Behavior of 7075-T73 Aluminum Alloy, Mater. Trans., 2014, 55, p 1280–1285

E. Cirik and K. Genel, Effect of Anodic Oxidation on Fatigue Performance of 7075-T6 Alloy, Surf. Coat. Technol., 2008, 202, p 5190–5201

M. Shahzad, M. Chaussumier, R. Chieragatti, F. Rezai-Aria, and C. Mabru, Influence of Surface Treatments on Fatigue Life of Al 7010 Alloy, J. Mater. Process Technol., 2010, 13, p 1821–1826

M. Chaussumier, C. Mabru, M. Shahzad, R. Chieragatti, and F. Rezai-Aria, A predictive Fatigue Life Model for Anodized 7050 Aluminium Alloy, Int. J. Fatigue, 2013, 48, p 205–213

P.N. Adler, R. Delasi, and G. Geschwind, Influence of Microstructure on the Mechanical, Metall. Trans., 1972, 3, p 3191–3200

F. Viana, A.M.P. Pinto, H.M.C. Santos, and A.B. Lopes, Retrogression and Re-Ageing of 7075 Aluminium Alloy: Microstructural Characterization, J. Mater. Process Technol., 1999, 92–93, p 54–59

S.P. Knight, N. Birbilis, B.C. Muddle, A.R. Trueman, and S.P. Lynch, Correlations Between Intergranular Stress Corrosion Cracking, Grain-Boundary Microchemistry, and Grain-Boundary Electrochemistry for Al-Zn-Mg-Cu Alloys, Corros. Sci., 2010, 52, p 4073–4080

American Society for Testing and Materials, Standard Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products, ASTM B557–10, American Society for Testing and Materials, West Conshohocken, 2014

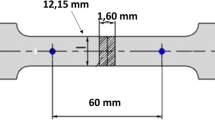

Japanese Industrial Standard Committee, Method of Rotating Bending Fatigue Testing of Metals, Japanese Industrial Standard Committee, JIS Z2274, Tokyo, 1978

K. Gopala Krishna, K. Sivaprasad, T.S.N. Sankara Narayanan, and K.C. Hari Kumar, Localized Corrosion of an Ultrafine Grained Al-4Zn-2Mg Alloy Produced by cryorolling, Corros. Sci., 2012, 60, p 82–89

M. Cabibbo, Microstructure Strengthening Mechanisms in Different Equal Channel Angular Pressed Aluminum Alloys, Mater. Sci. Eng. A Struct., 2013, 560, p 413–432

T. Zhai, X.P. Jiang, J.X. Li, M.D. Garratt, and G.H. Bray, The Grain Boundary Geometry for Optimum Resistance to Growth of Short Fatigue Cracks in High Strength Al-Alloys, Int. J. Fatigue, 2005, 27, p 1202–1209

Acknowledgments

We gratefully acknowledge the financial support from the Ministry of Science and Technology of the Republic of China (MOST 103-2221-E-008-026-MY2). Many thanks also to National Central University for providing the SEM and TEM equipments and to National Sun-Yat Sen University for the EBSD analyses.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shih, TS., Liao, TW. & Hsu, WN. Effects of Cryogenic Forging and Anodization on the Mechanical Properties of AA 7075-T73 Aluminum Alloys. J. of Materi Eng and Perform 25, 1211–1218 (2016). https://doi.org/10.1007/s11665-016-1946-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-1946-2