Abstract

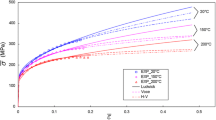

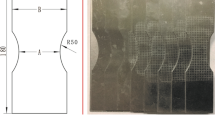

The objective of this work is to experimentally and numerically determine the influence of plastic anisotropy on the forming limit curve (FLC) for a heat-treated (300 °C-1 h) AA1100 aluminum alloy sheet. The FLCs were obtained by the Nakajima test, where the anisotropy effect on the FLC was evaluated using hourglass-type samples taken at 0°, 45°, and 90° with respect to the sheet rolling direction. The effect of crystal orientations on the FLC is investigated using three micro-macro averaging schemes coupled to a Marciniak and Kuczynski (MK) analysis: the tangent viscoplastic self-consistent (VPSC), the tuned strength αVPSC, and the full-constraint Taylor model. The predicted limit strains in the left-hand side of the FLC agree well with experimental measurements along the three testing directions, while differences are found under biaxial stretching modes. Particularly, MK-VPSC predicts an unexpected limit strain profile in the right-hand side of the FLC for samples tested along the transverse direction. Only MK-αVPSC, with a tuning factor of 0.2, predicts satisfactorily the set of FLC measurements. Finally, the correlation of the predicted limit strains with the predicted yield surface by each model was also discussed.

Similar content being viewed by others

References

S. Keeler and W. Backofen, Plastic Instability and Fracture in Sheet Stretched over Rigid Punches, ASM Trans. Q., 1963, 56, p 25–48

G.M. Goodwin, Application of Strain Analysis to Sheet Metal Forming Problems in the Press Shop, La Metallurgia Italiana (No. 680093), SAE Technical Paper, 1968, 60, p 764–774

S. Stören and J.R. Rice, Localized Necking in Thin Sheet, J. Mech. Phys. Solids, 1975, 23, p 421–441

K. Marciniak and K. Kuczynski, Limit Strains in the Process of Stretch-Forming Sheet Metal, Int. J. Mech. Sci., 1967, 9, p 609–620

R. Chiba, H. Takeuchi, M. Kuroda, T. Hakoyama, and T. Kuwabara, Theoretical and Experimental Study of Forming-Limit Strain of Half-Hard AA1100 Aluminium Alloy Sheet, Comput. Mater. Sci., 2013, 77, p 61–71

K. Inal, K. Neale, and A. Aboutajeddine, Forming Limit Comparison for FCC and BCC Sheets, Int. J. Plast., 2005, 21, p 1255–1266

R. Knockaert, Y. Chastel, and E. Massoni, Forming Limits Prediction Using Rate-Independent Polycrystalline Plasticity, Int. J. Plast., 2002, 18, p 231–247

M. Kuroda and V. Tvergaard, Forming Limit Diagrams for Anisotropic Metal Sheets with Different Yield Criteria, Int. J. Solids Struct., 2000, 37, p 5037–5059

W.B. Lee and X.Y. Wen, A Dislocation-Model of Forming Limit Prediction in the Biaxial Stretching of Sheet Metals, Int. J. Mech. Sci., 2006, 48, p 134–144

P.D. Wu, S.R. MacEwen, D.J. Lloyd, and K.W. Neale, Effect of Cube Texture on Sheet Metal Formability, Mater. Sci. Eng. A, 2004, 364, p 182–187

K. Yoshida, T. Ishizaka, M. Kuroda, and S. Ikawa, The Effects of Texture on Formability of Aluminum Alloy Sheets, Acta Mater., 2007, 55, p 4499–4506

C. Schwindt, F. Schlosser, M.A. Bertinetti, M. Stout, and J.W. Signorelli, Experimental and Visco-Plastic Self-consistent Evaluation of Forming Limit Diagrams for Anisotropic Sheet Metals: An Efficient and Robust Implementation of the M-K Model, Int. J. Plast., 2015. doi:10.1016/j.ijplas.2015.01.005

M.J. Serenelli, M.A. Bertinetti, and J.W. Signorelli, Investigation of the Dislocation Slip Assumption on Formability of BCC Sheet Metals, Int. J. Mech. Sci., 2010, 52, p 1723–1734

M.J. Serenelli, M.A. Bertinetti, and J.W. Signorelli, Study of Limit Strains for FCC and BCC Sheet Metal Using Polycrystal Plasticity, Int. J. Solids Struct., 2011, 48, p 1109–1119

J.W. Signorelli and M.A. Bertinetti, On the Role of Constitutive Model in the Forming Limit of FCC Sheet Metal with Cube Orientations, Int. J. Mech. Sci., 2009, 51, p 473–480

J.W. Signorelli, M.A. Bertinetti, and M.J. Serenelli, Experimental and Numerical Study of the Role of Crystallographic Texture on the Formability of an Electro-galvanized Steel Sheet, J. Mater. Process. Technol., 2012, 212, p 1367–1376

P.D. Wu, K.W. Neale, and V.D. Giessen, On Crystal Plasticity FLD Analysis, Proc. R. Soc. London A, 1997, 453, p 1831–1848

S.H. Choi, J.C. Brem, F. Barlat, and K.H. Oh, Macroscopic Anisotropy in AA5019A Sheets, Acta Mater., 2000, 48, p 1853–1863

H. Yuan, J. Li, D. Cai, Q. Yang, and W. Liu, Quantitative Analysis of Texture Evolution of Direct Chill Cast and Continuous Cast AA1100 Aluminium Alloys During Cold Rolling, Mater. Trans., 2007, 48, p 1886–1890

K. Yoshida, Y. Tadano, and M. Kuroda, Improvement in Formability of Aluminum Alloy Sheet by Enhancing Geometrical Hardening, Comput. Mater. Sci., 2009, 46, p 459–468

M.A. Bertinetti, C. Schwindt, and J.W. Signorelli, Effect of the Cube Orientation on Formability for FCC Materials: A Detailed Comparison Between Full-Constraint and Self-consistent Predictions, Int. J. Mech. Sci., 2014, 87, p 200–217

A.B. Lopes, F. Barlat, J.J. Gracio, J.F.F. Duarte, and E.F. Rauch, Effect of Texture and Microstructure on Strain Hardening Anisotropy for Aluminum Deformed in Uniaxial Tension and Simple Shear, Int. J. Plast., 2003, 19, p 1–22

J.W. Yoon, F. Barlat, J.J. Gracio, and E. Rauch, Anisotropic Strain Hardening Behavior in Simple Shear for Cube Textured Aluminum Sheets, Int. J. Plast., 2005, 21, p 2426–2447

J.W. Yoon, F. Barlat, R.E. Dick, and M.E. Karabin, Prediction of Six or Eight Ears in a Drawn Cup Based on a New Anisotropic Yield Functions, Int. J. Plast, 2006, 22, p 174–193

E. Nakamachi, C.L. Xie, H. Morimoto, K. Morita, and N. Yokoyama, FORMABILITY Assessment of FCC Aluminum Alloy Sheet by Using Elastic/Crystalline Viscoplastic Finite Element Analysis, Int. J. Plast., 2002, 18, p 617–632

C. K. Moy, M. Weiss, J. Xia, G. Sha, S.P. Ringera and G. Ranzia. Influence of heat treatment on the microstructure, texture and formability of 2024 aluminium alloy, Mater. Sci. Eng., 2012, 552A, p 48–60, in English.

J. Hu, J. Jonas, Y. Zhou, and T. Ishikawa, Influence of Damage and Texture Evolution on Limit Strain in Biaxially Stretched Aluminum Alloy Sheets, Mater. Sci. Eng. A, 1998, 251, p 243–250

R. Narayanasamy, R. Ravindran, K. Manonmani, and J. Satheesh, A Crystallographic Texture Perspective Formability Investigation of Aluminium 5052 Alloy Sheets at Various Annealing Temperatures, Mater. Des., 2009, 30, p 1804–1817

K. Velmanirajan, K. Anuradha, A. Syed, R. Abu Thaheer, R. Narayanasamy, R. Madhavan, and S. Suwas, Experimental Investigation of Forming Limit, Void Coalescence and Crystallographic Textures of Aluminum Alloy 8011 Sheet Annealed at Various Temperatures, Arch. Civ. Mech. Eng., 2014, 14, p 398–416

J. Sidor, A. Miroux, R. Petrov, and L. Kestens, Controlling the Plastic Anisotropy in Asymmetrically Rolled Aluminium Sheets, Philos. Mag., 2008, 88, p 3779–3792

S. Bruschi, T. Altan, D. Banabic, P.F. Bariani, A. Brosius, J. Cao, A. Ghiotti, M. Khraisheh, M. Merklein, and A.E. Tekkaya, Testing and Modeling of Material Behavior and Formability in Sheet Metal Forming, CIRP Ann., 2014, 63, p 727–749

R.A. Lebensohn and C.N. Tomé, A Self-consistent Approach for the Simulation of Plastic Deformation and Texture Development of Polycrystals: Application to Zr Alloys, Acta Metall. Mater., 1993, 41, p 2611–2624

J.W. Signorelli, M.A. Bertinetti, and P.A. Turner, Predictions of Forming Limit Diagrams Using a Rate-Dependent Polycrystal Self-consistent Plasticity Model, Int. J. Plast., 2009, 25, p 1–25

F. Bachmann, R. Hielscher, and H. Schaeben, Texture Analysis with MTEX—Free and Open Source Software Toolbox, Solid State Phenom., 2010, 160, p 63–68

A. Bragard, J. Baret, and H. Bonnarens, A Simplified Technique to Determine FLD at the Onset of Necking, Rapp. Cent. Rech. Mettall., 1972, 33, p 53–63

E.M. Viatkina, W.A. Brekelmans, and M. Geers, A Crystal Plasticity Based Estimate for Forming Limit Diagrams from Textural Inhomogeneities, J. Mater. Proc. Tech., 2005, 168, p 211–218

P.D. Wu, K.W. Neale, E. Van der Giessen, M. Jain, A. Makinde, and S.R. MacEwen, Crystal Plasticity Forming Limit Diagram Analysis of Rolled Aluminum Sheets, Metall. Mater. Trans. A, 1998, 29, p 527–535

Acknowledgments

The authors are grateful for the financial support provided by CONICYT (Fondecyt Project No. 1130404 and ECOS-CONICYT Project 2011 C11 E06). This work was funded by the CONICET (PIP 2011-2013 and PICT 2013-0588). The authors would like to thank C. Sobrero and R. Bolmaro for their significant help in the use of the x-ray equipment.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

To highlight the influence introduced by the fact that the model calibration considers results along RD, we repeated the simulations shown in Fig. 12 but assuming that all the material parameters at the single crystal level were calibrated using tensile test results along TD, and the MK imperfection factor was adjusted according to the corresponding limit strain at the plane strain condition also for TD specimens. The computed results do not exhibit qualitative differences between them, showing that the predicted limit strain profiles are not significantly sensitive to minor differences in the strain-stress behavior. As an example, Fig. 16 shows comparatively the limit strains values calculated using the MK-αVPSC model calibrated using RD or TD experimental data. Similar remarks can be done for the other two polycrystalline homogenization schemes used in the simulations (i.e., tangent VPSC and FC models) and for the diagonal direction (DD), considering either the power or saturation hardening law.

Rights and permissions

About this article

Cite this article

Durán, A.I., Signorelli, J.W., Celentano, D.J. et al. Experimental and Numerical Analysis on the Formability of a Heat-Treated AA1100 Aluminum Alloy Sheet. J. of Materi Eng and Perform 24, 4156–4170 (2015). https://doi.org/10.1007/s11665-015-1684-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1684-x