Abstract

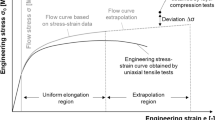

A solution to improve the formability of aluminum alloy sheets can consist in investigating warm forming processes. The optimization of forming process parameters needs a precise evaluation of material properties and sheet metal formability for actual operating environment. Based on the analytical M-K theory, a finite element (FE) M-K model was proposed to predict forming limit curves (FLCs) at different temperatures and strain rates. The influences of initial imperfection value (f 0) and material thermos-viscoplastic model on the FLCs are discussed in this work. The flow stresses of AA5086 were characterized by uniaxial tensile tests at different temperatures (20, 150, and 200 °C) and equivalent strain rates (0.0125, 0.125, and 1.25 s−1). Three types of hardening models (power law model, saturation model, and mixed model) were proposed and adapted to correlate the experimental flow stresses. The three hardening models were implemented into the FE M-K model in order to predict FLCs for different forming conditions. The predicted limit strains are very sensitive to the thermo-viscoplastic modeling of AA5086 and to the calibration of the initial geometrical imperfection which controls the onset of necking.

Similar content being viewed by others

References

T. Naka, G. Torikai, R. Hino, and F. Yoshida, The Effects of Temperature and Forming Speed on the Forming Limit Diagram for Type 5083 Aluminum-Magnesium Alloy Sheet, J. Mater. Process. Technol., 2001, 113(1–3), p 648–653

D. Li and A.K. Ghosh, Tensile Deformation Behavior of Aluminum Alloys at Warm Forming Temperatures, Mater. Sci. Eng. A, 2003, 352(1), p 279–286

D. Li and A.K. Ghosh, Biaxial Warm Forming Behavior of Aluminum Sheet Alloys, J. Mater. Process. Technol., 2004, 145(3), p 281–293

G. Palumbo and L. Tricarico, Numerical and Experimental Investigations on the Warm Deep Drawing Process of Circular Aluminum Alloy Specimens, J. Mater. Process. Technol., 2007, 184(1–3), p 115–123

W. Hui, Y.B. Luo, P. Friedman, M.H. Chen, and G.A.O. Lin, Warm Forming Behavior of High Strength Aluminum Alloy AA7075, Trans. Nonferrous Met. Soc. China, 2012, 22(1), p 1–7

X. Chu, L. Leotoing, D. Guines, and E. Ragneau, Temperature and Strain Rate Influence on AA5086 Forming Limit Curves: Experimental Results And Discussion on the Validity of the M-K Model, Int. J. Mech. Sci., 2014, 78, p 27–34

A.S. Khan and M. Baig, Anisotropic Responses, Constitutive Modeling and the Effects of Strain-Rate and Temperature on the Formability of an Aluminum Alloy, Int. J. Plast., 2011, 27, p 522–538

N. Abedrabbo, F. Pourboghrat, and J. Carsley, Forming of Aluminum Alloys at Elevated Temperatures—Part 1: Material Characterization, Int. J. Plast., 2006, 22, p 314–341

N. Abedrabbo, F. Pourboghrat, and J. Carsley, Forming of Aluminum Alloys at Elevated Temperatures—Part 2: Numerical Modeling and Experimental Verification, Int. J. Plast., 2006, 22, p 342–373

N. Abedrabbo, F. Pourboghrat, and J. Carsley, Forming of AA5182-O and AA5754-O at Elevated Temperatures Using Coupled Thermo-mechanical Finite Element Models, Int. J. Plast., 2007, 23(5), p 841–875

F.J. Zerilli and R.W. Armstrong, Dislocation-Mechanics-Based Constitutive Relations for Material Dynamics Calculation, J. Appl. Phys., 1987, 5, p 1816–1825

Y. Bergstrom, Dislocation Model for the Stress-Strain Behaviour of Polycrystalline Alpha-Iron with Special Emphasis on the Variation of the Densities of Mobile and Immobile Dislocations, Mater. Sci. Eng., 1969, 5, p 193–200

S. Nemat-Nasser and Y. Li, Flow Stress of fcc Polycrystals with Application to OFHC cu, Acta Mater., 1998, 46(2), p 565–577

G.Z. Voyiadjis and F.H. Abed, Microstructural Based Models for bcc and fcc Metals with Temperature and Strain Rate Dependency, Mech. Mater., 2005, 37(2–3), p 355–378

A. Rusinek and J.R. Klepaczko, Shear Testing of a Sheet Steel at Wide Range of Strain Rates and a Constitutive Relation with Strain-Rate and Temperature Dependence of the Flow Stress, Int. J. Plast., 2001, 17(1), p 87–115

A.H. van den Boogaard, P.J. Bolt, A Material Model for Warm Forming of Aluminium Sheet. In: VII International Conference on Computational Plasticity, COMPLAS, 2003

H. Vegter, C. Horn, Y. An, E.H. Atzema, H. Pijlman, T.H. van den Boogaard, and H. Huetink, Characterization and Modelling of the Plastic Material Behaviour and its Application in Sheet Metal Forming Simulation, VII International Conference on Computational Plasticity, Barcelona, 2003.

A. Rusinek and J.A.J.A. Rodríguez-Martínez, Thermo-viscoplastic Constitutive Relation for Aluminium Alloys, Modeling of Negative Strain Rate Sensitivity and Viscous Drag Effects, Mater. Des., 2009, 30(10), p 4377–4390

H. Aretz, An Extension of Hill’s Localized Necking Model, Int. J. Eng. Sci., 2010, 48, p 312–331

J.H. Sung, J.H. Kim, and R.H. Wagoner, A Plastic Constitutive Equation Incorporating Strain, Strain-Rate, and Temperature, Int. J. Plast., 2010, 26(12), p 1746–1771

F. Barlat and O. Richmond, Modelling Macroscopic Imperfections for the Prediction of Flow Localization and Fracture, Fatigue Fract. Eng. Mater. Struct., 2003, 26, p 311–321

C. Zhang, L. Leotoing, G. Zhao, D. Guines, and E. Ragneau, A Methodology for Evaluating Sheet Formability Combining the Tensile Test with the M-K Model, Mater. Sci. Eng. A, 2010, 528(1), p 480–485

S. Zhang, L. Leotoing, D. Guines, S. Thuillier, and S. Zang, Calibration of Anisotropic Yield Criterion with Conventional Tests or Biaxial Test, Int. J. Mech. Sci., 2014, 85, p 142–151

Acknowledgments

The authors would like to acknowledge the financial support from the National Natural Science Foundation of China (Grant No. 51405266) and Natural Science Foundation of Shandong Province (Grant No. ZR2014EEP003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chu, X., Leotoing, L., Guines, D. et al. Effect of Material Thermo-viscoplastic Modeling on the Prediction of Forming Limit Curves of Aluminum Alloy 5086. J. of Materi Eng and Perform 24, 3459–3470 (2015). https://doi.org/10.1007/s11665-015-1643-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1643-6