Abstract

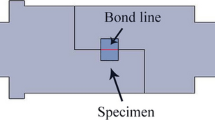

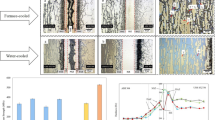

Experimental investigations have been done to verify the effects of hold time during transient liquid-phase bonding on joint microstructure and mechanical properties of a nickel-based single crystal superalloy. The superalloy was bonded at 1473-1513 K for 0.25-12 h in vacuum environment. A set of parameters, 1513 K for 10 h, was determined as the optimum bonding condition. SEM results revealed that the joint without the completion of isothermal solidification is comprised of four different distinct regions, namely, rapid solidification zone (RSZ), isothermal solidification zone (ISZ), diffusion zone, and base metal. EBSD data indicated that the ISZ across the centerline of the bond has an undifferentiated crystallographic orientation being the same as the base metal. At increasing hold times at 1513 K, RSZ and also borides would disappear and result in an improvement of mechanical properties. Mechanical property tests at elevated temperatures have been done to determine the joints’ quality. High-temperature creep rupture strength (for 100 h at 1373 K) and tensile strength (at 1273 K) of the joints could both attain 90% of those of the base metal.

Similar content being viewed by others

References

D.U. Kim and K. Nishimoto, Bonding Phenomena of Transient Liquid Phase Bonded Joints of a Ni Base Single Crystal Superalloy, Met. Mater. Int., 2002, 8, p 403–410

D.S. Duvall, W.A. Owczarski, and D.F. Paulonis, TLP* Bonding: A New Method for Joining Heat Resistant Alloys, Weld. J., 1974, 53, p 203–214

M.A. Arafin, M. Medraj, D.P. Turner, and P. Bocher, Transient Liquid Phase Bonding of Inconel 718 and Inconel 625 with BNi-2: Modeling and Experimental Investigations, Mater. Sci. Eng. A, 2007, 447, p 125–133

Y. Zhou, W.F. Gale, and T.H. North, Modelling of Transient Liquid Phase Bonding, Int. Mater. Rev., 1995, 40, p 181–196

K. Nishimoto, K. Saida, D. Kim, and Y. Nakao, Transient Liquid Phase Bonding of Ni-Base Single Crystal Superalloy, CMSX-2, ISIJ Int., 1995, 35, p 1298–1306

G. Zou, E. Xie, H. Bai, A. Wu, Q. Wang, and J. Ren, A Study on Transient Liquid Phase Diffusion Bonding of Ti-22Al-25Nb Alloy, Mater. Sci. Eng. A, 2009, 499, p 101–105

X. Wang, X. Li, and C. Wang, Effect of Two-Step Heating Process on Joint Microstructure and Properties During Transient Liquid Phase Bonding of Dissimilar Materials, Mater. Sci. Eng. A, 2013, 560, p 711–716

W.F. Gale, Transient Liquid Phase Bonding of Intermetallic Compounds, Mater. Sci. Forum, 2003, 426, p 1891–1896

W.F. Gale and D.A. Butts, Transient Liquid Phase Bonding, Sci. Technol. Weld. Joi., 2004, 9, p 283–300

C.E. Campbell and U.R. Kattner, A Thermodynamic Assessment of the Ni-Al-B System, J. Phase Equilib., 1990, 20, p 485–496

S. Chen, H. Tang, and X. Jing, Transient Liquid-Phase Bonding of T91 Steel Pipes Using Amorphous Foil, Mater. Sci. Eng. A, 2009, 499, p 114–117

V. Jalilvand, H. Omidvar, M.R. Rahimipour, and H.R. Shakeri, Influence of Bonding Variables on Transient Liquid Phase Bonding Behavior of Nickel Based Superalloy IN-738LC, Mater. Des., 2013, 52, p 36–46

Y. Yang, Y. Xie, M. Wang, and W. Ye, Microstructure and Tensile Properties of Nickel-Based Superalloy K417G Bonded Using Transient Liquid-Phase Infiltration, Mater. Des., 2013, 51, p 141–147

W. Li, T. Jin, X. Sun, Y. Guo, H. Guan, and Z. Hu, Study of Ni-Cr-Co-W-Mo-B Interlayer Alloy and Its Bonding Behaviour for a Ni-Base Single Crystal Superalloy, Scr. Mater., 2003, 48, p 1283–1288

B. Laux, S. Piegert, and J. Rösler, Braze Alloy Development for Fast Epitaxial High-Temperature Brazing of Single-Crystalline Nickel-Based Superalloys, Metall. Mater. Trans. A, 2009, 40, p 138–149

G.O. Cook and C.D. Sorensen, Overview of Transient Liquid Phase and Partial Transient Liquid Phase Bonding, J. Mater. Sci., 2011, 46, p 5305–5323

N. Sheng, B. Li, J. Liu, T. Jin, X. Sun, and Z. Hu, Influence of the Substrate Orientation on the Isothermal Solidification During TLP Bonding Single Crystal Superalloys, J. Mater. Sci. Technol., 2014, 30, p 213–216

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chai, L., Huang, J., Hou, J. et al. Effect of Holding Time on Microstructure and Properties of Transient Liquid-Phase-Bonded Joints of a Single Crystal Alloy. J. of Materi Eng and Perform 24, 2287–2293 (2015). https://doi.org/10.1007/s11665-015-1504-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1504-3