Abstract

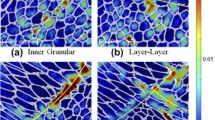

In this paper we propose a novel method, spherical indentation, for evaluation of the plastic properties of combined structures. Three-dimensional (3D) printed products, for example gradient metal alloys consisting of different kinds of material, contain interfaces that can act as weak points and threaten the mechanical reliability of products. Combined structures containing an interface between Cu alloy and Ag were prepared for testing. Samples were heat-treated at 100°C and 200°C for 3 h to optimize processing conditions. The indentation tensile properties of the samples were estimated by analyzing multiple loading–unloading curves obtained by use of the representative stress and strain method. A continuous increase in both yield strength and tensile strength was observed for the Cu alloy and the Cu/Ag interface after heat treatment at up to 200°C, because of precipitation hardening. These experimental results show that mechanical characterization of combined structures by spherical indentation is highly useful on the nano and micro scales.

Similar content being viewed by others

References

METI Journal, The potential of 3D printing. (METI Journal, 2013) http://www.meti.go.jp/english/publications/pdf/journal 2013_08a.pdf. August 2013.

I.D. Harris, Development and Implementation of Metals Additive Manufacturing (Deep Offshore Technology, 2011), http://ewi.org/eto/wp-content/uploads/2013/06/Additive-Manu facturing-DOT-Paper-2011.pdf. 2011.

I. Gibson, D.W. Rosen, and B. Stucker, Additive Manufacturing Technologies (Springer, Dordrecht, 2010), pp. 6–11, pp. 32–38.

I. Shishkovsky, F. Missemer, N. Kakovkina, and I. Smurov, Crystals 3, 517 (2013).

S. Copley, R. Martukanitz, W. Frazier, and M. Rigdon, Mechanical Properties of Parts Formed by Laser Additive Manufacturing (Advanced Materials & Processes, 2011), http://www.asminternational.org/documents/10192/1904083/amp16909p26.pdf/c31656cc-06c3-4642-bca6-d45c20c49b07. September 2011.

D.C. Hofmann, S. Roberts, R. Otis, J. Kolodziejska, R.P. Dillon, J.-O. Suh, A.A. Shapiro, Z.-K. Liu, and J.-P. Borgonia, Sci. Rep. (2014). doi:10.1038/srep053571.

M.F. Doerner and W.D. Nix, J. Mater. Res. 1, 601 (1986).

W.C. Oliver and G.M. Pharr, J. Mater. Res. 7, 1564 (1992).

S. Suresh and A.E. Giannakopoulos, Acta Mater. 46, 5755 (1998).

Y.H. Lee and D. Kwon, J. Mater. Res. 17, 901 (2002).

S.A.S. Asif, K.J. Wahl, and R.J. Colton, Rev. Sci. Inst. 70, 2408 (1999).

D.M. Shinozaki and Y. Lu, J. Elect. Mater. 26, 852 (1997).

J. Malzbender and G. de With, Surf. Technol. 135, 60 (2000).

X.Z. Hu and B.R. Lawn, Thin Solid Films 322, 225 (1998).

J.-H. Ahn and D. Kwon, J. Mater. Res. 16, 3170 (2001).

D. Tabor, Hardness of Metals (Oxford: Clarendon Press, 1951), p. 37.

E.-C. Jeon, M.-K. Baik, S.-H. Kim, B.-W. Lee, and D. Kwon, Key Eng. Mater. 297–300, 2152 (2005).

J.-Y. Kim, et al., Surf. Coat. Technol. 201, 4278 (2006).

G.E. Dieter, Mechanical Metallurgy (New York: McGraw Hill, 1986), p. 289.

C. Hardy, et al., J. Numer. Met. Eng. 3, 451 (1971).

K.L. Johnson, J. Mech. Phys. Solids 18, 115 (1970).

K.-W. Lee, et al., J. Phys. D 41, 074014 (2008).

A.M. Howatson, P.G. Lund, and J.D. Todd, Engineering Tables and Data (Netherlands: Springer, 1972), p. 41.

Y.V. Murty, Encycl. Mater. 2, 2483 (2008).

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) Grant funded by the Korea government (MSIP) (2010-0029211).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, WS., Kim, SG., Kim, YC. et al. Use of Spherical Instrumented Indentation to Evaluate the Tensile Properties of 3D Combined Structures. J. Electron. Mater. 44, 831–835 (2015). https://doi.org/10.1007/s11664-014-3593-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-014-3593-4