Abstract

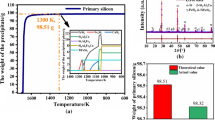

The Si8Al6Fe4Ca content in metallurgical-grade silicon (MG-Si) is one of the key parameters determining the quality of synthesized organosilicon monomers. However, the low content of Si8Al6Fe4Ca in MG-Si makes it difficult to perform quantitative research. Therefore, in this study, the content and formation characteristics of Si8Al6Fe4Ca were amplified by preparing Si–Fe–Al–Ca–Ti alloys. The formation mechanism and electromagnetic strengthening efficiency of Si8Al6Fe4Ca were determined by examining the precipitation thermodynamics and experimental results of intermetallics. The results showed that the Si–Fe–Al–Ca–Ti alloy melt simulated the precipitation of intermetallics in MG-Si. Si8Al6Fe4Ca formed due to the transformation of FeSi2 and Si2Al2Ca and the precipitation of impurity elements in the melt. When no electromagnetic field was applied to the alloy melt, there was a large error between the experimental and theoretical values of Si8Al6Fe4Ca within the studied concentration range. The amount of Si8Al6Fe4Ca in the Si–20wt pctFe–15 wt pctAl–5 wt pctCa–2.5 wt pctTi alloy melt reached the maximum (32.30 wt pct), but the precipitation efficiency was only 64.88 pct. When an electromagnetic field was applied to the alloy melt, the average strengthening rate of Si8Al6Fe4Ca was 23.86 pct, and the maximum strengthening rate was 41.97 pct (Si–20 wt pctFe–15 wt pctAl–2.5 wt pctCa–2.5 wt pctTi). This work improved the formation of the intermetallic compound Si8Al6Fe4Ca during the solidification of MG-Si, which lays a theoretical foundation and provides technical support for the preparation of MG-Si for high-quality silicon.

Similar content being viewed by others

References

Y. Zhang, J. Li, H. Liu, Y. Ji, Z. Zhong, and F. Su: ChemCatChem, 2019, vol. 12(11), pp. 2757–79. https://doi.org/10.1002/cctc.201900385.

S. Li, X. Deng, J. Wen, K. Wei, and W. Ma: Intermetallics, 2021, vol. 128, p. 106987. https://doi.org/10.1016/j.intermet.2020.106987.

J.M. Bablin, A.C. Crawford, D.C. DeMoulpied, and L.N. Lewis: Ind. Eng. Chem. Res., 2003, vol. 15(42), pp. 3555–65. https://doi.org/10.1021/ie020334s.

C. Wang, T. Liu, Y. Huang, G. Wang, and J. Wang: Ind. Eng. Chem. Res., 2013, vol. 15(52), pp. 5282–86. https://doi.org/10.1021/ie303515q.

Y. Zhang, Y. Ji, J. Li, H. Liu, X. Hu, Z. Zhong, and F. Su: Nano Res., 2018, vol. 2(11), pp. 804–19. https://doi.org/10.1007/s12274-017-1689-x.

J. Acker and K. Bohmhammel: J. Organomet. Chem., 2008, vol. 15(693), pp. 2483–93. https://doi.org/10.1016/j.jorganchem.2008.04.026.

Y. Zhang, Y. Ji, J. Li, H. Liu, Z. Zhong, and F. Su: J. Catal., 2017, vol. 348, pp. 233–45. https://doi.org/10.1016/j.jcat.2017.02.030.

P. Zhang, J.H. Duan, G.H. Chen, and W.W. Wang: Sci. Rep., 2015, vol. 1(5), pp. 1–8. https://doi.org/10.1038/srep08827.

F. Zhang, Z. Zhang, Y. Liu, Z. Zhong, and W. Xing: Ind. Eng. Chem. Res., 2016, vol. 40(55), pp. 10600–08. https://doi.org/10.1021/acs.iecr.6b02028.

H. Zhang, S. Guo, J. Wu, D. Wu, K. Wei, and W. Ma: Hydrometallurgy, 2021, vol. 204, p. 105715. https://doi.org/10.1016/j.hydromet.2021.105715.

D. Liu, X. Deng, J. Tai, S. Yang, K. Wei, and W. Ma: Silicon, 2022, https://doi.org/10.1007/s12633-022-01876-4.

G. Qian, L. Zhou, S. Li, Z. Wang, and L. Sun: Acs Sustain. Chem. Eng., 2021, vol. 33(9), pp. 11179–93. https://doi.org/10.1021/acssuschemeng.1c03381.

Y. He, W. Ma, A. Xing, M. Hu, S. Liu, X. Yang, J. Li, S. Du, and W. Zhou: Mater. Sci. Semicon. Proc., 2022, vol. 141, p. 106438. https://doi.org/10.1016/j.mssp.2021.106438.

X. Deng, L. Zhou, K. Wei, and W. Ma: Vacuum, 2022, vol. 207, p. 111581. https://doi.org/10.1016/j.vacuum.2022.111581.

S. Yang, X. Wan, K. Wei, W. Ma, and Z. Wang: Waste Manag., 2020, vol. 120, pp. 820–27. https://doi.org/10.1016/j.wasman.2020.11.005.

A. Hosseinpour and L.T. Khajavi: Miner. Process. Extr. Metall. Rev., 2018, vol. 5(39), pp. 308–18. https://doi.org/10.1080/08827508.2018.1459616.

S. Li, X. Deng, C. Zhang, J. Wen, J. Wu, K. Wei, and W. Ma: J. Alloy Compds., 2020, vol. 831, p. 154888. https://doi.org/10.1016/j.jallcom.2020.154888.

S. Yang, X. Wan, K. Wei, W. Ma, and Z. Wang: Miner. Eng., 2021, vol. 169, p. 106966. https://doi.org/10.1016/j.mineng.2021.106966.

S. Li, X. Deng, K. Wei, W. Ma, and J. Wu: J. Alloy Compds., 2020, vol. 816, p. 152507. https://doi.org/10.1016/j.jallcom.2019.152507.

X. Deng, K. Wei, J. Wen, and W. Ma: J. Alloy Compds., 2022, vol. 890, p. 161832. https://doi.org/10.1016/j.jallcom.2021.161832.

Y.V. Meteleva-Fischer, Y. Yang, R. Boom, B. Kraaijveld, and H. Kuntzel: Intermetallics, 2012, vol. 25, pp. 9–17. https://doi.org/10.1016/j.intermet.2012.02.009.

L. Zhou, S. Li, Q. Tang, X. Deng, K. Wei, and W. Ma: J. Alloy Compds., 2021, vol. 882, p. 160570. https://doi.org/10.1016/j.jallcom.2021.160570.

S. Han, N. Tan, K. Wei, and W. Ma: Sep. Purif. Technol., 2022, vol. 280, p. 119815. https://doi.org/10.1016/j.seppur.2021.119815.

K. Zhu, J. Hu, W. Ma, K. Wei, T. Lv, and Y. Dai: J. Cryst. Growth, 2019, vol. 522, pp. 78–85. https://doi.org/10.1016/j.jcrysgro.2019.05.012.

L. Zhou, K. Zhu, X. Deng, T. Yan, J. Hu, and K. Wei: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 2262–71. https://doi.org/10.1007/s11663-022-02527-0.

Y. Yang, K. Zhang, Y. Li, X. Feng, and T. Lou: Procedia Manuf., 2019, vol. 37, pp. 621–26. https://doi.org/10.1016/j.promfg.2019.12.097.

L. Zhou, K. Zhu, T. Yan, J. Hu, K. Wei, and W. Ma: Metall. Mater. Trans. B, 2022, vol. 2B, pp. 1283–94. https://doi.org/10.1007/s11663-021-02395-0.

T. Yoshikawa and K. Morita: J. Cryst. Growth, 2009, vol. 3(311), pp. 776–79. https://doi.org/10.1016/j.jcrysgro.2008.09.095.

K. Zhu, W. Ma, K. Wei, Y. Lei, J. Hu, T. Lv, and Y. Dai: J. Alloy Compds., 2018, vol. 750, pp. 102–10. https://doi.org/10.1016/j.jallcom.2018.02.161.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No.U1902219), the Yunnan Young and Middle-aged Academic and Technical Leader Reserve Talent Project (No. 2018HB009), the Yunnan Distinguished Young Scholar Science Foundation (No. 202101AV070007), the Major Science and Technology Projects in Yunnan Province (No. 202002AB080002), the Sichuan Science and Technology Program (2021YJ0548), and the Research Project of Panzhihua University (2020ZD002).

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, L., Wei, K., Zhu, K. et al. Formation Mechanism and Strengthening Method of Si8Al6Fe4Ca During the Solidification of Metallurgical-Grade Silicon. Metall Mater Trans B 54, 2216–2228 (2023). https://doi.org/10.1007/s11663-023-02828-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02828-y