Abstract

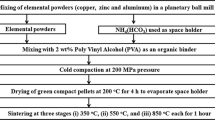

Aluminum AlSi8Mg4 alloy foams were produced by the powder compact foaming route using different parameters for the uniaxial powder compaction step. Compaction time, pressure, and temperature were varied and were found to influence both the density of the foamable precursor and the peak expansion reached during foaming. While peak expansion cannot be related to any single pressing parameter alone in a simple way, a clear dependence of expansion on the precursor density was found. Densification to a relative density between 97.5 and 99 pct yielded volume expansions of the foam up to 880 pct. Lower densities result in weaker foaming, due to insufficient encapsulation of the blowing agent; in addition, we were surprised to find that higher densification also has an adverse effect on peak expansion, most likely due to the elimination of nucleation centers or the effect of entrapped compressed air. Precursor microstructures were analyzed to identify the mechanisms leading to the observed density dependence of expansion.

Similar content being viewed by others

Notes

PHILIPS is a trademark of Philips Electronic Instruments Corp., Mahwah, NJ.

Gemini is a Trademark of Carl Zeiss NTS GmbH, Oberkochen, Germany.

Audi is a trademark of AUDI AG, Ingolstadt, Germany.

References

B.C. Allenand, M.W. Mote, and A.M. Sabroff: U.S. Patent No. 3,087,807, 1959.

J. Baumeister: German Patent No. DE 4018360 C1, 1990.

F. Baumgärtner, I. Duarte, and J. Banhart: Adv. Eng. Mater., 2000, vol. 2, pp. 168–74.

L.-P. Lefebvre, J. Banhart, and D.C. Dunand: Adv. Eng. Mater., 2008, vol. 10, pp. 775–87.

I. Duarte and J. Banhart: Acta Mater., 2000, vol. 48, pp. 2349–62.

F. Garcia-Moreno, M. Fromme, and J. Banhart: Adv. Eng. Mater., 2004, vol. 6, pp. 416–20.

D. Lehmhus and G. Rausch: Adv. Eng. Mater., 2004, vol. 6, pp. 313–30.

B. Matijasevic, J. Banhart, S. Fiechter, O. Görke, and N. Wanderka: Acta Mater., 2006, vol. 8, pp. 864–69.

D. Lehmhus and M. Busse: Adv. Eng. Mater., 2004, vol. 6, pp. 391–96.

H.-M. Helwig: Doctoral Thesis, Technische Universität Berlin, Berlin, 2009, submitted.

C. Körner, F. Berger, M. Arnold, C. Stadelmann, and R.F. Singer: Mater. Sci. Technol., 2000, vol. 16, pp. 781–84.

F. Garcia-Moreno, N. Babcsan, and J. Banhart: Coll. Surf., A, 2005, vol. 263, pp. 290–94.

S. Asavavisithchai and A.R. Kennedy: Adv. Eng. Mater., 2006, vol. 8, pp. 810–15.

L. Bonaccorsi and E. Proverbio: Adv. Eng. Mater., 2006, vol. 8, pp. 864–69.

J. Banhart and H.-W. Seeliger: Adv. Eng. Mater., 2008, vol. 10, pp. 793–802.

Kenndaten von Werkzeugstählen–ORVAR SUPREME Warmarbeitsstahl, Boehler-Uddeholm GmbH, Düsseldorf, 1998, 12 pp.

H.-M. Helwig and J. Banhart: in Cellular Metals and Metal Foaming Technology, J. Banhart, M.F. Ashby, and N.A. Fleck, eds., MIT - Verlag, Berlin, Germany, 2003, pp. 165–68.

University of Texas Health Science Center, home page of UTHSCSA ImageTool, http://ddsdx.uthscsa.edu/dig/itdesc.html.

A. Dudka, F. Garcia-Moreno, N. Wanderka, and J. Banhart: Acta Mater., 2008, vol. 56, pp. 3990–4001.

A.R. Kennedy and S. Asavavisithchai: Mater. Sci. Forum, 2002, vols. 396–402, pp. 251–58.

A. Kennedy and S. Asavavisithchai: in Porous Metals and Metal Foaming Technology, H. Nakajima and N. Kanetake, eds., The Japanese Institute of Metals (JIM), Sendai, Japan, 2005, pp. 139–44.

W. Schatt: Sintervorgänge, VDI-Verlag, Düsseldorf, Germany, 1992.

F. von Zeppelin, M. Hirscher, H. Stanzick, and J. Banhart: Compos. Sci. Technol., 2003, vol. 63, pp. 2293–2300.

V. Bohsle, E.G. Baburaj, M. Miranova, and K. Salama: Mater. Sci. Eng., A, 2003, vol. A356, pp. 190–99.

A. Ibrahim, C. Körner, and R.F. Singer: Adv. Eng. Mater., 2008, vol. 10, pp. 845–48.

G.A. Young and J.R. Scully: Acta Mater., 1998, vol. 46, pp. 6337–49.

J. Banhart, D. Bellmann, and H. Clemens: Acta Mater., 2001, vol. 49, pp. 3409–20.

D. Pan: Masterthesis, TU Berlin, Berlin 2009.

S. Vatchiants and N. Manunkyan: in Porous Metals and Metal Foaming Technology, H. Nakajima and N. Kanetake, eds., The Japanese Institute of Metals (JIM), Sendai, Japan, 2005, pp. 195–99.

P. Schaeffler, G. Hanko, H. Mitterer, and P. Zach: in MetFoam 2007: Porous Metals and Metallic Foams, L.P. Lefebvre, J. Banhart, and D. Dunand, eds., DEStech Publications, Inc., Lancaster, PA, 2007, pp. 7–10.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 9, 2008.

Rights and permissions

About this article

Cite this article

Helwig, HM., Hiller, S., Garcia-Moreno, F. et al. Influence of Compaction Conditions on the Foamability of AlSi8Mg4 Alloy. Metall Mater Trans B 40, 755–767 (2009). https://doi.org/10.1007/s11663-009-9264-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-009-9264-9