Abstract

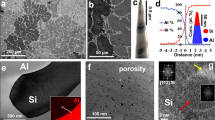

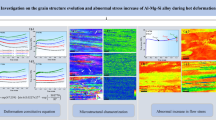

Al alloys are known to experience extensive grain refinement during shear-assisted processing techniques, an effect driven by dynamic dislocation density generation and microstructural restoration assisted by deformation-induced heating. In order to predict the extent of grain refinement of Al–Si alloys in response to the friction-assisted shear deformation, a coupling of Finite Element Method and the Kinetic Monte Carlo Potts Model is utilized in this work. We show that our microstructure-sensitive model simulates the microstructural response of Al–Si alloys to influence of shear deformation and temperature, as a recrystallization and grain growth phenomenon. The microstructural evolution of Al–Si alloys was simulated as a function of deformation, temperature, and Si composition. Simulations were performed on microstructures representing alloy compositions corresponding to pure Al, Al–1 pct Si, and Al–4 pct Si, for temperatures ranging 300 °C to 400 °C and several different magnitudes of shear. Model predictions were validated with experimental results of the grain size and orientation changes in Al–Si alloys during pin-on-disk tribometer experiments. Further, these simulations predict that the increase in Si composition results in larger heterogeneities in strain distribution under shear and commensurately tepid recrystallization. This demonstrates a plausible physical explanation for variations in grain size observed in tribometric experiments.

Similar content being viewed by others

References

S. Whalen, V. Joshi, N. Overman, D. Caldwell, C. Lavender, and T. Skszek: in Magnesium Technology 2017, K.N. Solanki, D. Orlov, A. Singh, and N.R. Neelameggham, eds., Springer, 2017, pp. 315–22.

S. Whalen, N. Overman, V. Joshi, T. Varga, D. Gra, and C. Lavender: Mater. Sci. Eng. A., 2019, vol. 755, pp. 278–88.

J.T. Darsell, N.R. Overman, V.V. Joshi, S.A. Whalen, and S.N. Mathaudhu: J. Mater. Eng. Perform., 2018, vol. 27, pp. 4150–61.

N.R. Overman, S.A. Whalen, M.E. Bowden, M.J. Olszta, K. Kruska, T. Clark, E.L. Stevens, J.T. Darsell, V.V. Joshi, X. Jiang, K.F. Mattlin, and S.N. Mathaudhu: Mater. Sci. Eng. A., 2017, vol. 701, pp. 56–68.

P. Zhao, Y. Wang, and S.R. Niezgoda: Int. J. Plast., 2018, vol. 100, pp. 52–68.

N.J. Petch: Prog. Met. Phys., 1954, vol. 5, pp. 1–52.

Z.C. Cordero, B.E. Knight, and C.A. Schuh: Int. Mater. Rev., 2016, vol. 61, pp. 495–512.

I. Charit and R.S. Mishra: Scr. Mater., 2008, vol. 58, pp. 367–71.

B. Gwalani, M. Olszta, S. Varma, L. Li, A. Soulami, E. Kautz, S. Pathak, A. Rohatgi, P.V. Sushko, S. Mathaudhu, C.A. Powell, and A. Devaraj: Commun. Mater., 2020, vol. 1, pp. 1–8.

Z. Zhang, Q. Wu, M. Grujicic, and Z.Y. Wan: J. Mater. Sci., 2016, vol. 51, pp. 1882–95.

M. Jamalian, V. V Joshi, S. Whalen, C. Lavender, and D.P. Field: in 18th International Conference on Textures of Materials, IOP Publishing, 2018, pp. 1–8.

C.G. Figueroa, R. Schouwenaars, J. Cortés-Pérez, R. Petrov, and L. Kestens: Mater. Charact., 2018, vol. 138, pp. 263–73.

K.G. Basavakumar, P.G. Mukunda, and M. Chakraborty: J. Mater. Process. Technol., 2007, vol. 186, pp. 236–45.

S. Meenia, F. Khan, S. Babu, R.J. Immanuel, S.K. Panigrahi, and J.G.D. Ram: Mater. Charact., 2016, vol. 113, pp. 134–43.

A.G. Rao, K.R. Ravi, B. Ramakrishnarao, V.P. Deshmukh, A. Sharma, N. Prabhu, and B.P. Kashyap: Metall. Mater. Trans. A., 2013, vol. 44A, pp. 1519–29.

S. Jin, Z. Luo, X. An, X. Liao, J. Li, and G. Sha: J. Mater. Sci. Technol., 2021, vol. 68, pp. 199–208.

S.G. Shabestari and F. Shahri: J. Mater. Sci., 2004, vol. 39, pp. 2023–32.

S. Richmire and M. Haghshenas: in IOP Conference Series: Materials Science and Engineering, vol. 174, IOP Publishing, 2017, pp. 1–8.

L.C.L. Ko and J.Q. Da Fonseca: in ICAA13 Pittsburgh, H. Weiland, A.D. Rollett, and W.A. Cassada, eds., Springer, 2012, pp. 1607–12.

E. Damavandi, S. Nourouzi, S.M. Rabiee, R. Jamaati, and J.A. Szpunar: J. Alloy. Compunds., 2021, vol. 858, pp. 1–18.

P.A. Manohar, M. Ferry, and T. Chandra: ISIJ Int., 1998, vol. 38, pp. 913–24.

C.S. Smith: Trans. Am. Inst. Min. Eng., 1948, vol. 175, pp. 15–51.

A. Khalkhali and M. Saranjam: Int. J. Automot. Eng., 2015, vol. 5, pp. 932–38.

M.P. Iqbal, A. Tripathi, R. Jain, R.P. Mahto, S.K. Pal, and P. Mandal: Int. J. Mech. Sci., 2020, vol. 185, p. 105882.

W. Frazier, C. Wang, Z. Xu, and N. Overman: Metall. Mater. Trans. A., 2020, vol. 51, pp. 533–44.

C. Wang, A. Soulami, Z. Xu, G. Cheng, S. Hu, D. Burkes, W.E. Frazier, K.S. Choi, X. Wang, X. Hu, C.A. Lavender, and V.V. Joshi: Process Modeling of U-10wt % Mo Alloys Using Integrated Computational Materials Engineering, PNNL-28640. Richland, WA: Pacific Northwest National Laboratory, 2019.

G. Cheng, X. Hu, W.E. Frazier, C.A. Lavender, and V.V. Joshi: Mater. Sci. Eng. A., 2018, vol. 736, pp. 41–52.

S.A. Langer, A.C.E. Reid, R.C. Lua, E.R. Garcia, and V.R. Coffman: Int. J. Mater. Prod. Technol., 2009, vol. 35, pp. 361–73.

P.S. Sahni, G.S. Grest, M.P. Anderson, and D.J. Srolovitz: Phys. Rev. Lett., 1983, vol. 50, pp. 263–66.

P.S. Sahni, D.J. Srolovitz, G.S. Grest, M.P. Anderson, and S.A. Safran: Phys. Rev. B., 1983, vol. 28, pp. 2705–16.

M.P. Anderson, D.J. Srolovitz, G.S. Grest, and P.S. Sahni: Acta Metall., 1984, vol. 32, pp. 783–91.

G.S. Grest, D.J. Srolovitz, and M.P. Anderson: Acta Metall., 1985, vol. 33, pp. 509–20.

K. Adam, J.M. Root, Z. Long, and D.P. Field: J. Mater. Eng. Perform., 2017, vol. 26, pp. 207–13.

P.E. Goins and W.E. Frazier: Acta Mater., 2020, vol. 188, pp. 79–91.

E.A. Holm, M.A. Miodownik, and A.D. Rollett: Acta Mater., 2003, vol. 51, pp. 2701–16.

V. Tikare and E. Holm: J. Am. Ceram. Soc., 1998, vol. 81, pp. 480–84.

W.E. Frazier, G.S. Rohrer, and A.D. Rollett: Acta Mater., 2015, vol. 96, pp. 390–98.

E.R. Homer, V. Tikare, and E.A. Holm: Comp Mat Sci., 2013, vol. 69, pp. 414–23.

E. Ising: Zeitschrift fur Phys., 1925, vol. 31, pp. 253–58.

R.B. Potts and J.C. Ward: Prog. Theor. Phys., 1955, vol. 13, pp. 38–46.

P.E. Goins and E.A. Holm: Comput. Mater. Sci., 2016, vol. 124, pp. 411–19.

D. Zöllner: Comput. Mater. Sci., 2014, vol. 86, pp. 99–107.

W.E. Frazier, S. Hu, and V.V. Joshi: Comput. Mater. Sci., 2020, vol. 185, p. 109945.

D. Raabe: Acta Mater., 2000, vol. 48, pp. 1617–28.

S.P. Chen, D.N. Hanlon, S. Van Der Zwaag, Y.T. Pei, and J.T.M. Dehosson: J. Mater. Sci., 2002, vol. 37, pp. 989–95.

B. Gwalani, W. Fu, M. Olszta, J. Silverstein, D. Yadav, P. Manimunda, A. Guzman, K. Xie, A. Rohatgi, S. Mathaudhu, C. Powell, P. Sushko, and Y. Li: Under Submission, 2021.

M. Lewandowska, T. Wejrzanowski, and K.J. Kurzydłowski: J. Mater. Sci., 2008, vol. 43, pp. 7495–7500.

M.C. Santos, A.R. Machado, and M.A.S. Barrozo: Temperature in Machining of Aluminum Alloys, https://www.intechopen.com/chapters/60618.

A. Rollett, F. Humphreys, G.S. Rohrer, and M. Hatherly: Recrystallization and Related Annealing Phenomena, 2nd ed. Elsevier Ltd, Amsterdam, 2004.

R.D. Doherty, D.A. Hughes, F.J. Humphreys, J.J. Jonas, D.J. Jensen, M.E. Kassner, W.E. King, T.R. McNelley, H.J. McQueen, and A.D. Rollett: Mater. Sci. Eng. A., 1997, vol. 238, pp. 219–74.

X.M. Chen, L.T. Li, W.Z. Chen, W.C. Zhang, L.X. Zhang, Y.D. Qiao, and E.D. Wang: Mater. Sci. Eng. A., 2017, vol. 708, pp. 351–59.

L. Chen, F. Yuan, P. Jiang, J. Xie, and X. Wu: Mater. Sci. Eng. A., 2017, vol. 694, pp. 98–109.

R.A. Vandermeer and N. Hansen: Acta Mater., 2008, vol. 56, pp. 5719–27.

S.L. Thomas, K. Chen, J. Han, P.K. Purohit, and D.L. Srolovitz: Nat. Commun., 2017, vol. 8, pp. 1–12.

T.J. Rupert, D.S. Gianola, Y. Gan, and K.J. Hemker: Science., 2009, vol. 326, pp. 1686–90.

M. Winning, G. Gottstein, and L.S. Shvindlerman: Acta Mater., 2002, vol. 50, pp. 353–63.

D.A. Molodov, V.A. Ivanov, and G. Gottstein: Acta Mater., 2007, vol. 55, pp. 1843–48.

S.L. Thomas, A.H. King, and D.J. Srolovitz: Acta Mater., 2016, vol. 113, pp. 301–10.

Z.Y. Ma, S.R. Sharma, and R.S. Mishra: Mater. Sci. Eng. A., 2006, vol. 433, pp. 269–78.

Acknowledgments

This work was supported by the Laboratory Directed Research and Development program at Pacific Northwest National Laboratory (PNNL) as part of the Solid Phase Processing Science initiative. PNNL is a multiprogram national laboratory operated for the U.S. Department of Energy (DOE) by Battelle Memorial Institute under Contract No. DE-AC05-76RL0-1830.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted June 8, 2021; accepted January 13, 2022.

Rights and permissions

About this article

Cite this article

Frazier, W.E., Li, L., Gwalani, B. et al. An Approach for the Microstructure-Sensitive Simulation of Shear-Induced Deformation and Recrystallization in Al–Si Alloys. Metall Mater Trans A 53, 1450–1461 (2022). https://doi.org/10.1007/s11661-022-06606-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06606-4