Abstract

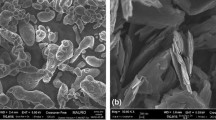

AA2124 reinforced with graphene (G), silicon carbide nanoparticles (SiCnp), and graphene-coated SiCnp (GCSiCnp) were fabricated and characterized. GCSiCnp reinforcement was fabricated by ball milling, followed by mixing and milling the reinforcements with AA2124 powders. Consolidation was achieved by cold compaction and hot extrusion (HE). The powders’ morphology and structural evolution were characterized with XRD and SEM. Microhardness and tensile properties were also characterized. Increasing the fillers’ content beyond 5 wt pct deteriorated the composites’ mechanical properties due to the agglomeration of the fillers. Adding 5 wt pct GCSiCnp increased the hardness, specific strength, and modulus of the composite and decreased ductility. Furthermore, 5 wt pct SiCnp induced severe lattice strain by intra-granular dispersion strengthening. The GCSiCnp filler strengthened the Al-matrix via the strong interfacial bonding of the intercalated inter-granular lamination of the hybrid particles within the Al-matrix and the intra-granular dispersion strengthening associated with the individual SiCnp. Adding 5 wt pct G lowered the HE composite’s density and hardness significantly, while the sliding of G-intercalated layers coating the Al-grains facilitated plastic flow along the extrusion direction and enhanced the strength and ductility of the composite compared to that containing 5 wt pct GCSiCnp.

Similar content being viewed by others

References

Goushegir S.M., Dos Santos J. F., and Amancio-Filho S. T. Mater. Des. 2014, 54, pp.196–206

Kala H., Mer K. K. S., and Kumar S. Procedia Mater. Sci. 2014, 6. pp.1951–1960.

Dinaharan I., Kalaiselvan K., and Murugan N. Compos. Commun. 2017, 3, pp.42–46.

Jayalakshmi S, Gupta M (2015) Metallic Amorphous Alloy Reinforcements in Light Metal Matrices Springer Briefs in Materials. Springer, New York

Liu, L. Ke Q., Liu F., Huang C., and Xing L. Mater. Des. 2013, 45. pp.343–348.

Casati R. and Vedani M. Met., 2014, 4, pp.65–83.

Li J. L., Xiong Y. C., Wang X. D., Yan S. J., Yang C., He W. W., Chen J. Z., Wang S. Q. Zhang X. Y.,and Dai S. L. Mater. Sci. Eng. A 2015, 626, pp.400–405.

Zhao X. J., Xiao L. R., Zhao Z. W., Guo L., Ru H. Q., Zhang N., and Chen D. L. Ceram. Int. 2014, 40, pp.14295–14303.

Fadavi Boostani A., Tahamtan S., Jiang Z. Y., Wei D., Yazdani S., Azari Khosroshahi R., Taherzadeh Mousavian R., Xu Zhang J., and Gong D. Compos. Part A Appl. Sci. Manuf. 2015, 68, pp.155–163.

Kollo L., Leparoux M., Bradbury C. R., Jäggi C., Carreño-Morelli E., and Rodríguez-Arbaizar M. J. Alloys Compd. 2010, 489, pp.394–400.

Bastwros M., Kim G.Y., Zhu C., Zhang K., Wang S., Tang X., and Wang X. W. Compos. Part B Eng. 2014, 60, pp.111–118.

Wang J., Li Z., Fan G., Pan H., Chen Z., and Zhang D. Scr. Mater. 2012, 66, pp.594–597

Khadem H., Nategh S.A., and Yoozbashizadeh S. J. Alloys Compd. 2011, 509, pp.2221–2226.

Saheb N., Aliyu I. K., Hassan S. F., and Al-Aqeeli N. Mater. (Basel) 2014, 6, pp. 6748–6767.

Dorri Moghadam A., Omrani E., Menezes P. L., and Rohatgi P. K. Compos. Part B Eng. 2015, 77, pp. 402–420.

Carreño-Gallardo C., Estrada-Guel I., López-Meléndez C., and Martínez-Sánchez R. J. Alloys Compd. 2014, 586, pp. 68–72.

Wu Y. and Lvernia E. J. Scr. Met. Mater. 1992, 27, pp.173-178.

Conlon K. T. and Wilkinson D. S. Mater. Sci. Eng. A 2001, 317, pp.108–114.

Huang Y., Su Y., Guo X., Guo Q., Ouyang Q., Zhang G. and Zhang D. J. Alloys Compd., 2017, 711, pp. 22–30.

El-Ghazaly A., Anis G., and Salem H. G. Composites Part A. 2017, 95, pp.325–336.

A. El Ghazaly, M. Shokeir, S.N. El Moghazi, A. Fathy, M.M. Emara, and H.G. Salem: in Proceeding of the 3rd Pan American Materials Congress 2017, pp. 115–23.

Salem H. G., El-Eskandarany S., and Kandil A., Abdul Fattah H. J. Nanomater. 2009, 2009, pp.1-12.

Mendoza-Duartea J. M., Guela E., Hernandezb F. C. R., Gallardoa C. C., Meléndezc C. L. and Sáncheza R. M. Mater. Res. 2016, 19, pp. 13-19

V.D. Mote, Y. Purushotham, and B.N. Dol: J. Appl. Theor. Phys., 2012, 6, pp. 1–8.

Zhu H. and Qi F. Rare Met. 2011, 30, pp. 550-554.

El Daly A. A., Abdel Hameed M., Hashish M. and Daoush W. M. Mater. Sci. Eng. A 2013, 559, pp.384-393.

Reddy A. P., Krishna P. V., Rao E. N., and Murthy N. V. Mater. Today Proceedings. 2017, 4, pp.359-397.

Deaquino-Lara R, Gutiérrez-Castañeda E, Estrada-Guel I, Hinojosa-Ruiz G, Garcia-Sánchez E, Herrera-Ranirez JM, Pérez-Bustamante R, Martínez-Sánchez R (2014) Mater Des 53:1104-1111

Fallahdoost H., Nouri A., and Azimi A. J. Phys. Chem. Solids 2016, 93, pp.137-144.

Mann S., Kumar R., and Jindal V. K. Journal of RSC Advances 2017, 36, pp.1-21.

Baradeswaran A. and Laya Perumal A. E. Composites Part B 2014, 56, pp.464-471.

Bhowmik A, Dey D, Biswas A (2020) Mater Today Proc. https://doi.org/10.1016/j.matpr.2020.02.436

Ted Cuo M. L. and Tsao C. Y. A. Compos. Sci. and Technol. 2000, 60, pp.65-74.

Kaushik N. Ch. and Rao R. N. Tribol. Int. 2016, 96, pp.184-190

Challapalli S (2001) Mechanical Alloying and Milling. CRC Press, New York

Reddy M. P., Shakoor R. A., Parande G., Manakari V., Ubaid F., Mohamed A., and Gupta M. Prog. Nat. Sci.: Mater. Int. 2017, 27, pp.606-614.

Cheng-jin HU, Hong-ge YAN, Ji-hua CHEN, and Bin SU. Trans. Nonferrous Met. Soc. China 2016, 26, pp.1259-1268.

Salem H. G. and Sadek A. A. J.Mater.Eng. perform. 2010, 19, pp.356-367.

Eldesouky A, Johnsson M, Svengren H, Attallah MM, Salem HG (2014) J Alloys Compd. 609:215-221

J.L. Hernandez-Rivera, H. Medellín-Castilo, D.F. De Lange, and L.G. Mejía-Rodríguez: in ASME 2014 International Mechanical Engineering Congress and Exposition, 2014.

Sun Y, Zhang C, Liu B, Meng Q, Ma S, Dai W (2018) Metals 8:499-511

Blanco Fernandez, J., Jimenez Macias, E., Saenz-Diez Muro, J. C., Caputi, L. S., Miriello, D., De Luca, R., & Carvajal Fals, H. D. Metals, 2018 8(2), pp. 113-126.

Shao P, Yang W, Zhang Q, Meng Q, Tan X, Xiu Z, Qiao J, Yu Z, Wu G (2018) Composites A 109:151-162

Mohammad Islam, Yasir Khalid, Iftikhar Ahmad, Abdulhakim A. Almajid, Amine Achour, Theresa J. Dunn, Aftab Akram, and Saqib Anwar: Metal. and Mat Trans A 2018, 49, pp. 2963-2976.

Acknowledgments

The authors of the work would like to acknowledge the Youssef Jamil Science and Technology Research Center for facilitating the use of equipment. The authors would also like to acknowledge the assistance of Eng. Dina Fouad for her time and effort.

Funding

This work was supported by the American University in Cairo.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted April 16, 2019.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Shokeir, M., El Moghazi, S., Omara, A.F. et al. Influence of Graphene, SiCnp, and G/SiCnp Hybrid Fillers on the Strengthening Mechanisms of Al-Matrix. Metall Mater Trans A 51, 3280–3298 (2020). https://doi.org/10.1007/s11661-020-05721-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05721-4