Abstract

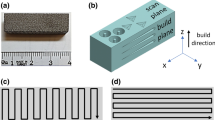

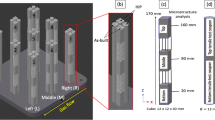

Laser and electron beam melting are prime technologies in metallic powder bed additive manufacturing in which parts are built layer by layer using high energy source. The technology is at a level where each layer can be as thin as 50 µm. Melting and solidification of each powder layer is typically accompanied by some subsurface melting to assure adherence and fusion of layers. In addition to anisotropic mechanical behavior of material caused by layering phenomenon, it is expected that the local mechanical behavior and microstructure vary throughout each build. In this manuscript, local and global mechanical behavior of Ti6Al4V parts produced using electron beam melting technology is investigated using bulk scale mechanical testing and nanoindentation. Parts fabricated in different build orientation were tested at different strain rates at a large scale. The experiment showed that strength is minimal perpendicular to the build plate. Additionally, material exhibited different local mechanical properties relative to distance from base plate. Investigation of the microstructure indicated very distinguished variations in the grain size and alpha and beta phase formation of material in different locations of part relative to build plate. Strength reduction in perpendicular direction is examined and explained through understanding of the microstructure and plastic deformation mechanism in α phase and prior β grains.

Similar content being viewed by others

References

J. Sieniawski, and W. Ziaja: Titanium Alloys—Advances in Properties Control, ISBN 978-953-51-1110-8, Published: May 15, 2013 under CC BY 3.0 license. ©The Author(s).

R. Pederson: Thesis, Luena University of Technology, 2002.

J.W., Foltz, B. Welk, P.C., Collins, H. L. Fraser, J.C. Williams, Metall. Mater. Trans. A, Vol.42 A, March 2011, pp. 645-650.

P.S. Follansbee, G.T. Gray III, Metall. Trans. A, 20 (1989), pp. 863–874.

A. Antonysamy, J. Meyer, and P. B. Prangnell, Mater. Charact., vol. 84, pp. 153–168, Oct. 2013.

L. Ladani, J. Razmi, S.F. Choudhury, J. Eng. Mater. Technol., Volume 136, Issue 3, 031006-1-031006-7 (Jun 05, 2014).

L.E. Murr, E.V. Esquivel, S.A. Quinones, S.M. Gaytan, M.I. Lopez, E. Y. Martinez, F. Medina, D.H. Hernandez, E. Martinez, J.L. Martinez, S.W. Stafford, D.K. Brown, T. Hoppe, W. Meyers, U. Lindhe, and R.B.Wicker, Mater. Charact., Vol. 60, pp. 96-105, 2009.

L.E. Murr, S.M. Gaytan, F. Medina, E.Martinez, D.H. Hernandez, L. Martinez, M.I. Lopez, R.B. Wicker, and S. Collins: Solid Freeform Fabr. Symp. Proc., 2009, pp. 374–97.

L.E. Murr, S.A. Quinones, S.M. Gaytan, M.I. Lopez, A. Rodela, E.Y. Martinez, D.H. Hernandez, E. Martinez, F. Medina, R.B. Wicker, Mech. Behav. Biomed. Mater. Vol. 2, pp. 20-, 2009.

S.M. Gaytan, L.E. Murr, F. Medina, E. Martinez, M.I. Lopez, R.B. Wicker, Mater. Technol., Vol. 24, pp. 180-190, 2009.

L.E. Murr, E. Martinez, S.M. Gaytan, D.A. Ramirez, B.I. Machado, P.W. Shindo, J.L. Martinez, F. Medina, J. Wooten, D. Ciscel, U. Ackelid, and R.B. Wicker, Metall. Mater. Trans. A, November 2011, Volume 42, Issue 11, pp 3491-3508.

L. E. Murr, S. M. Gaytan, A. Ceylan, E. Martinez, J. L. Martinez, D. H. Hernandez, B. I. Machado, D. A. Ramirez, F. Medina, and S. Collins, Acta Mater., vol. 58, no. 5, pp. 1887–1894, Mar. 2010.

E. Rawn: “Oak Ridge National Laboratory Develops 3D Printing Process at the Microscale”, 2014. ArchDaily. Accessed 21 Dec 2014. http://www.archdaily.com/?p=566979.

U. Lindhe, O.L. Harrysson: Solid Freeform Fabrication Symposium Proceedings, 2003, pp. 433–38.

J.R. Schroeder: Advanced Manufacturing Technology Changes the Way Implants are Designed and Produced. Fall, BONEZone, 2006, pp. 17–20.

S. Thundal, 2008. Adv. Mater. Process 166, 60–62.

V. Maier, K. Durst, J. Mueller, B. Backes, H.W. Höppel, and M. Göken, 2011, J. Mater. Res., 26, pp. 1421-1430.

R. Li, L. Riesterb, T. R. Watkins, P.J. Blaub, and A. J. Shih, (2008). J. Mater. Sci. Eng. A, (472). 115-124.

L. Qiana, M. Lib, Z. Zhoua, H. Yanga, and X. Shia, (2005), Surf. Coat. Technol., 195 (2-3). 264-271.

M.B. Mathisen: Norvegian University of Science and Technology, Master Thesis, 2012.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 29, 2014.

Rights and permissions

About this article

Cite this article

Ladani, L. Local and Global Mechanical Behavior and Microstructure of Ti6Al4V Parts Built Using Electron Beam Melting Technology. Metall Mater Trans A 46, 3835–3841 (2015). https://doi.org/10.1007/s11661-015-2965-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2965-6