Abstract

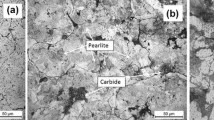

A spherical carbonyl iron powder was consolidated by the field-assisted hot pressing technique using graphite tools at two different temperatures, both above the austenitizing temperature. The microstructures obtained exhibited a compositional gradient in carbon along the consolidated material. Thus, the outer rim of the cylindrical samples was composed of cementite and pearlite that gradually turned to pearlite, leading to a fully ferritic microstructure at the core of the sample. The increase in the temperature has led to a higher introduction of carbon within the sample. The interposition of a thin tungsten foil between the graphite die/punches and the powders has significantly reduced the diffusion of the carbon through the iron matrix and has suppressed the microstructural anisotropy.

Similar content being viewed by others

References

M. Omori: Mater. Sci. Eng. A, 2000, vol. 287, pp. 183-88.

R. Orrù, R. Licheri, A.M. Locci, A. Cincotti, G. Cao: Mater. Sci. Eng. R, 2009, vol. 63, pp. 127-287.

S. Grasso,Y. Sakka,G. Maizza: Sci. Technol. Adv. Mater., 2009, Vol. 10, pp. 1-24.

D.V. Quach, J.R. Groza, A. Zavaliangos, and U. Anselmi-Tamburini: 10—Fundamentals and Applications of Field/Current Assisted Sintering: Woodhead Publishing Series in Metals and Surface Engineering, Woodhead Publishing, Abington, 2010, pp. 249–74.

O. Guillon, J. González-Julian, B. Dargatz, T. Kessel, G. Schierning, J. Räthel, M. Herrmann: Adv. Eng. Mater., 2014, vol. 16, pp. 830-49.

S. Libardi, M. Zadra, F. Casari, A. Molinari: Mater. Sci. Eng. A, 2008, vol. 478, pp. 243-50.

M. Pellizzari, A. Fedrizzi, M. Zadra: Mater. Des., 2011, vol. 32, pp. 1796-1805.

S. Pandya, K.S. Ramakrishna, A.R. Annamalai, A. Upadhyaya: Mater. Sci. Eng. A, 2012, vol. 556, pp. 271-77.

R. Muñoz-Moreno, E.M. Ruiz-Navas, B. Srinivasarao, J.M. Torralba: J. Mater. Sci. Technol., 2014, vol. 30, pp. 1145-54.

B. Srinivasarao, J.M. Torralba, M.A. Jabbari Taleghani, M.T. Pérez-Prado: Mater. Lett, 2014, Vol. 123, pp. 75-78,

K. Feng, Y. Yang, M. Hong, J. Wu, S. Lan: J. Mater. Process. Technol., 2008, vol. 208, pp. 264-69.

J. Räthel, M. Herrmann, W. Beckert: J. Eur. Ceram. Soc., 2009, vol. 29, pp. 1419-25.

G. Bernard-Granger, N. Benameur, C. Guizard, M. Nygren: Scr. Mater., 2009, vol. 60, pp. 164-67.

Y. Liu, Z. Jin: Ceram. Int., 2012, vol. 38, pp. 217-22.

W. Wang, H. Kou, S.Liu, Y. Shi, J. Li, X. Feng, Y. Pan, Y. Li, J. Guo: Ceram. Int., 2015, vol. 41, pp. 2576-81.

H.K.D.H. Bhadeshia, R.W.K. Honeycombe: Steels, Third Edition, Butterworth-Heinemann, Oxford, 2006, pp. 39-70.

R.P Smith: Acta Metal., 1953, vol. 1, pp. 578-87.

G.G. Tibbetts: J. Appl. Phys., 1980, vol. 51, pp. 4813-16.

M. Fáberová, R. Bureš, E. Dudrová: Powder Metall. Prog., 2009, vol. 9, pp. 212-18.

E.O. Hall: Proc. Phys. Soc. B., 1951, vol. 64, pp. 747-53.

N.J. Petch: J. Iron Steel Inst., 1953, vol. 174, pp. 25-32.

E. Lassner, W.D. Schubert: Tungsten: Properties, Chemistry, Technology of the Element, Alloys, and Chemical Compounds, Kluwer Academic/Plenum Publishers, New York, 1999.

A.K. Dutta: Phys. Rev., 1953, vol. 90, pp. 187–92.

C.N. Hooker, A.R. Ubbelohde, D.A.Young: Proc. Roy. Soc. A., 1965, vol. 284, pp. 17-31.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 16, 2015.

Rights and permissions

About this article

Cite this article

García-Junceda, A., Acebo, L. & Torralba, J.M. Study and Suppression of the Microstructural Anisotropy Generated During the Consolidation of a Carbonyl Iron Powder by Field-Assisted Hot Pressing. Metall Mater Trans A 46, 3192–3198 (2015). https://doi.org/10.1007/s11661-015-2919-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2919-z