Abstract

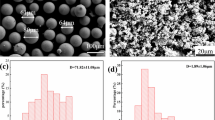

An IN718 alloy coating was prepared by high-power diode laser cladding. 980STA standard heat treatment and direct aging (DA) were employed to improve the properties of this coating. The niobium segregation in the as-deposited coating and the heat-treated coating had been investigated using a scanning electron microscope (SEM) equipped with energy-dispersive X-ray spectroscopy (EDAX). The results showed that 980STA standard heat treatment improved the microhardness of the coating significantly, and Laves concentration was reduced from 30.6 vol pct to about 11.4 vol pct after 980STA. The niobium concentration in Laves of the 980STA-treated coating was higher than that of DA-treated coating and as-deposited coating. Only a small portion of niobium in the coating was precipitated in the form of γ″ during the 980STA heat treatment. The rest of niobium was the alloying element for solid-solution strengthening and the constituent element of Laves. The niobium segregation facilitated the formation of Laves.

Similar content being viewed by others

References

R.F. Decker and C.T. Sims: The Superalloys: Vital High Temperature Gas Turbine Materials for Aerospace and Industrial Power, C.T. Sims and W.C. Hagel, eds., Wiley, New York, NY, 1972, pp. 33–77.

M.K. Miller, S.S. Babu, and M.G. Burke: Mater. Sci. Eng. A, 1999, vol. 270A, pp. 14–18.

T. Antonsson and H. Fredriksson: Metall. Mater. Trans. B, 2005, vol. 36B, pp. 85–96.

S. Gobbi, L. Zhang, J. Norris, K.H. Richter, and J.H. Loreau: J. Mater. Process. Technol., 1996, vol. 56, pp. 333–45.

R. Vincent: Acta Metall., 1985, vol. 33, pp. 1205–16.

K. Vishwakarma, N. Richards, and M. Chaturvedi: Mater. Sci. Eng. A, 2008, vol. 480A, pp. 517–28.

K. Sivaprasad and S.G.S. Raman: Metall. Mater. Trans. B, 2008, vol. 39B, pp. 2115–27.

D. Clark, M.R. Bache, and M.T. Whittaker: J. Mater. Process. Technol., 2008, vol. 203, pp. 439–48.

C. Radhakrishna, K.P. Rao, and S. Srinivas: J. Mater. Sci. Lett., 1995, vol. 14, pp. 1810–12.

H. Qi, M. Azer, and A. Ritter: Metall. Mater. Trans., 2009, vol. 40A, pp. 2410–22.

G. Knorovsky, M. Cieslak, T. Headley, A. Romig, and W. Hammetter: Metall. Trans. A, 1989, vol. 20A, pp. 2149–58.

J.N. DuPont, J.G. Nawrocki, and M.L. Griffith: Proc. Solid Freeform Fabrication Conference, D.L. Bourell, J.J. Beaman, R.H. Crawford, H.L. Marcus, K.L. Wood, and J.W. Barlow, eds., University of Texas at Austin, Austin, TX, 2001, pp. 232–41.

F. Liu, X. Lin, C. Huang, M. Song, G. Yang, and W. Huang: J. Alloys Compd., 2011, vol. 509, pp. 4505–09.

A. Jung and A. Schnell: Int. J. Fatigue, 2008, vol. 30, pp. 286–91.

W. Liu and J. DuPont: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 3397–3406.

M. Gäumann, C. Bezençon, P. Canalis, and W. Kurz: Acta Mater., 2001, vol. 49, pp. 1051–62.

A.A. Jawwad, M. Strangwood, and C. Davis: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 1237–47.

J.F. Radavich: Proc. Conf. Speralloy 718—Metallurgy and Application, E.A. Loria, eds., TMS, Warrendale, PA, 1989, pp. 229–40.

C. Radhakrishna and K.P. Rao: J. Mater. Sci., 1997, vol. 32, pp. 1977-84.

J.J. Schirra, R.H. Caless, and R.W. Hatala: Superalloys 718, 625 and Various Derivatives, E.A. Loria, eds., TMS, Pittsburgh, PA, 1991, pp. 375-88.

W.D. Morrow and B.R. Patterson: J. Mater. Energ. Sys., 1986, vol. 8, pp. 38-43.

M. Sozanska, A. Maciejny, C. Dagbert, J. Galland, and L. Hyspecká: Mater. Sci. Eng. A, 1999, vols. 273-5A, pp. 485–90.

G.M. Reddy, C.V.S. Murthy, K.S. Rao, and K.P. Ral: Int. J. Manuf. Technol., 2009, vol. 43, pp. 671-80.

M.J. Cieslak, G.A. Knorovsky, T.J. Headley, and J.A.D. Romig: Proc. Conf. Speralloy 718—Metallurgy and Application, E.A. Loria, eds., TMS, Warrendale, PA, 1989, pp. 59–68.

X. Cai: Fundamentals of Materials Science and Engineering, Shanghai Tiaotong University Press, Shanghai, P.R. China, 2010.

W. Kurz and D.J. Fisher: Fundamentals of Solidification, 4th ed., Enfield Publishing & Distribution Company, Enfield, NH, 1998.

Z.M. Wang, K. Guan, M. Gao, X.Y. Li, X.F. Chen, and X.Y. Zeng: J. Alloys Compd., 2012, vol. 513, pp. 518–23.

J. Huang, P.L. Nie, Y.C. Zhang, H.G. Liu, Z.G. Li, and Y.X. Wu: Rare Metal, Mater. Eng., 2011, vol. 40, pp. 283–87.

G. Bi, A. Gasser, K. Wissenbach, A. Drenker, and R. Poprawe: Opt. Lasers Eng., 2006, vol. 44, pp. 1348–59.

D.G.L. Prakash, M.J. Walsh, D. Maclachlan, and A.M. Korsunsky: Int. J. Fatigue, 2009, vol. 31, pp. 1966–77.

A. Strondl, R. Fischer, G. Frommeyer, and A. Schneider: Mater. Sci. Eng. A, 2008, vol. 480A, pp. 138–47.

Acknowledgments

The authors gratefully acknowledge the financial support of the Ministry of Science and Technology of the People’s Republic of China (Grant No. 2009DFB50350) and the National Natural Science Foundation of China (Grant No. 50971091).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 11, 2012.

Rights and permissions

About this article

Cite this article

Zhang, Y., Li, Z., Nie, P. et al. Effect of Heat Treatment on Niobium Segregation of Laser-Cladded IN718 Alloy Coating. Metall Mater Trans A 44, 708–716 (2013). https://doi.org/10.1007/s11661-012-1459-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1459-z