Abstract

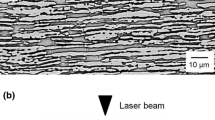

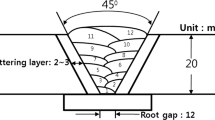

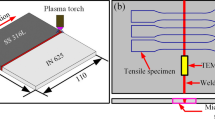

The correlation between the mechanical properties and ferrite volume fraction (approximately 40, 50, and 60 Ferrite Number [FN]) in duplex stainless steel weld metals were investigated by changing the Cr content in filler wires with a flux-cored arc-welding (FCAW) process. The interpass temperature was thoroughly maintained under a maximum of 423 K (150 °C), and the heat input was also sustained at a level under 15 KJ/cm in order to minimize defects. The microstructure examination demonstrated that the δ-ferrite volume fraction in the deposited metals increased as the Cr/Ni equivalent ratio increased, and consequently, chromium nitride (Cr2N) precipitation was prone to occur in the ferrite domains due to low solubility of nitrogen in this phase. Thus, more dislocations are pinned by the precipitates, thereby lowering the mobility of the dislocations. Not only can this lead to the strength improvement, but also it can accentuate embrittlement of the weld metal at subzero temperature. Additionally, the solid-solution strengthening by an increase of Cr and Mo content in austenite phase depending on the reduction of austenite proportion also made an impact on the increase of the tensile and yield strength. On the other hand, the impact test (at 293 K, 223 K, and 173 K [20 °C, –50 °C, and –100 °C]) showed that the specimen containing about 40 to 50 FN had the best result. The absorbed energy of about 40 to 50 J sufficiently satisfied the requirements for industrial applications at 223 K (–50 °C), while the ductile-to-brittle transition behavior exhibited in weldment containing 60 FN. As the test temperature decreased under 223 K (–50 °C), a narrow and deep dimple was transformed into a wide and shallow dimple, and a significant portion of the fracture surface was occupied by a flat cleavage facet with river patterns.

Similar content being viewed by others

References

I. Varol and W.A. Baeslack, III: Mater. Charact., 1997, vol. 39, pp. 553–73.

J.C. Lippold and D.J. Kotecki: Welding Metallurgy and Weldability of Stainless Steels, 1st ed., Hoboken, NJ, 2005, pp. 230–34.

H. Ericksson and S. Bernhardsson: Corros. Sci., 1991, vol. 47, pp. 719–25.

J. Oredsson and S. Bernhardsson: Mater. Perf., 1983, vol. 22, pp. 35–42.

J.I. Son, S.S. Kim, J.H. Lee, and B.H. Choi: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 1617–25.

Y.H. Jang, S.S. Kim, and J.H. Lee: Mater. Sci. Eng. A, 2005, vol. 396, pp. 302–10.

S.B. Kim, K.W. Paik, and Y.K. Kim: Mater. Sci. Eng. A, 1998, vol. 247, pp. 67–74.

J. Li, Y. Xu, X. Xiao, J. Zhao, L. Jiang, and J. Hu: Mater. Sci. Eng. A, 2009, vol. 527, pp. 245–51.

S. Kou: Welding Metallurgy, 2nd ed., Wiley, Hoboken, NJ, 2003, pp. 3–29.

R.N Gunn: Duplex Stainless Steel, Woodhead Publishing Ltd., Abington, VA, 1997, pp. 110–19.

J.R. Davis: Stainless Steels (ASM Specialty Handbook), ASM International, Materials Park, OH, 1994.

V. Muthupandi, P. Bala Srinivasan, V. Shankar, S.K. Seshadri, and S. Sundaresan: Mater. Lett., 2005, vol. 59, pp. 2305–09.

Y.H. Park and Z.H. Lee: Mater. Sci. Eng. A, 2001, vol. 297, pp. 78–84.

M. Kemp, A. Van Bennekom, and F.P.A. Robinson: Mater. Sci. Eng. A, 1995, vol. 199, pp.183–94.

J. Sakai, I. Matsushima, Y. Kamemura, M. Tanimura, and T. Osuka: Duplex Stainless Steels, R.A. Lula, ed., ASM International, Materials Park, OH, 1983, pp. 211–31.

R.A. Perren, T. Suter, C. Solenthaler, G. Gullo, P.J. Uggowitzer, H. Böhni, and M.O. Speidel: Corros. Sci., 2001, vol. 43, pp. 727–45.

D.J. Kotecki and T.A. Sievert: Weld. J., 1992, vol. 71, pp. 171–78.

D.E. Nelson and W.A. Baeslack, III: Mater. Charact., 1997, vol. 39, pp. 467–77.

R. Badji, M. Bouabdallah, B. Bacroix, C. Kahloun, B. Belkessa, and H. Maza: Mater. Charact., 2008, vol. 59, pp. 447–53.

D.J. Lee, J.C. Byun, J.H. Sung, and H.W. Lee: Mater. Sci. Eng. A, 2009, vol. 513, p. 154.

Y.H. Kim, D.J. Lee, J.C. Byun, K.H. Jung, J.I. Kim, H.J. Lee, Y.T. Shin, S.H. Kim, and H.W. Lee: Mater. Des., 2011, vol. 32, pp. 330–36.

A.J. Ramirez, J.C. Lippold, and S.D. Brandi: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 1575–97.

S.D. Brandi and A.J. Ramirez: Duplex Stainless Steels ’97, Proc. Conf., KCI, Maastricht, the Netherlands, 1997, pp. 405–10.

V.S. Moura, L.D. Limda, J.M. Pardal, A.Y. Kina, R.R.A. Corte, and S.S.M. Tavares: Mater. Charact., 2008, vol. 59, pp. 1127–32.

B. Deng, Z. Wang, Y. Jiang, T. Sun, J. Xu, J. Li: Corros. Sci., 2009, vol. 51, pp. 2969–75.

J.C. Lippold and A.M. Al-Rumaih: Duplex Stainless Steels ’97, Proc. Conf., KCI, Maastricht, the Netherlands, 1997, pp. 405–10.

S.D. Brandi, J.C. Lippold, and W. Lin: Duplex Stainless Steels ’97, Proc. Conf., KCI, Maastricht, the Netherlands, 1997, pp. 411–18.

T. Ogawa and T. Koseki: Weld. J., 1989, vol. 68, pp. 181–91.

T.G. Gooch: ASM Conference Proc. on Duplex Stainless Steels, 1982, pp. 573–602.

J.D. Kordatos, G. Fourlaris, and G. Papadimitiou: Scripta Mater., 2001, vol. 44, pp. 401–08.

J.W. Simmons: Mater. Sci. Eng. A, 1996, vol. 207, p. 159.

F.R.N. Nabarro: Mater. Sci. Eng. A, 1989, vol. 113, pp. 315–26.

S. Pak and L. Karlsson: Scand. J. Metall., 1990, vol. 19, pp. 19–23.

J.W. Chan: Adv. Cryog. Eng., 1992, vol. 55, pp. 34–38.

D.J. Lee, J.C. Byun, J.H. Sung, and H.W. Lee: Mater. Sci. Eng. A, 2009, vols. 513–514, pp. 154–59.

G. Han, S. Fukuyama, and K. Yokogawa: Mater. Sci. Technol., 1999, vol. 15, pp. 905–09.

R. Peierls: Proc. Phys. Soc., 1940, vol. 52, pp. 34–37.

G. Schoeck: Mater. Sci. Eng. A, 2005, vol. 400, pp. 7–17.

B. Deng, Z. Wang, Y. Jiang, T. Sun, J. Xu, and J. Li: Corros. Sci., 2009, vol. 51, pp. 2969–75.

R. Kacar: Mater. Des., 2004, vol. 25, pp. 1–9.

R. Kacar and M. Acarer: Mater. Sci. Eng. A, 2003, vol. 363, p. 290.

H. Sieurin and R. Sandstom: Eng. Fract. Mech., 2006, vol. 73, p. 377.

Metals and Ceramics Information Center: SEM/TEM Fractography Handbook, Metals and Ceramics Information Center, Huntington, CA, 1975.

S. Bonnet, J. Bourgoin, J. Champredonde, D. Guttmann, and M. Guttmann: Mater. Sci. Technol., 1990, vol. 6, pp. 221–29.

K. Chandra, R. Singhal, V. Kain, and V.S. Raja: Mater. Sci. Eng. A, 2010, vol. 527, pp. 3904–12.

Acknowledgment

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (Grant 20100021533).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 18, 2011.

Rights and permissions

About this article

Cite this article

Kang, D.H., Lee, H.W. Effect of Different Chromium Additions on the Microstructure and Mechanical Properties of Multipass Weld Joint of Duplex Stainless Steel. Metall Mater Trans A 43, 4678–4687 (2012). https://doi.org/10.1007/s11661-012-1310-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1310-6