Abstract

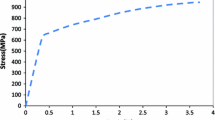

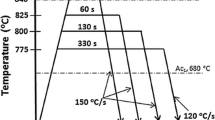

The flow behavior of dual-phase (DP) steels is modeled on the finite-element method (FEM) framework on the microscale, considering the effect of the microstructure through the representative volume element (RVE) approach. Two-dimensional RVEs were created from microstructures of experimentally obtained DP steels with various ferrite grain sizes. The flow behavior of single phases was modeled through the dislocation-based work-hardening approach. The volume change during austenite-to-martensite transformation was modeled, and the resultant prestrained areas in the ferrite were considered to be the storage place of transformation-induced, geometrically necessary dislocations (GNDs). The flow curves of DP steels with varying ferrite grain sizes, but constant martensite fractions, were obtained from the literature. The flow curves of simulations that take into account the GND are in better agreement with those of experimental flow curves compared with those of predictions without consideration of the GND. The experimental results obeyed the Hall-Petch relationship between yield stress and flow stress and the simulations predicted this as well.

Similar content being viewed by others

References

J. Shaw, B. Engl, C. Espina, E.C. Oren, and Y. Kawamoto: New Steel Sheet and Steel Bar Products and Processing, D.W. Anderson, ed., SAE-SP 1685, Society of Automotive Engineers (SAE), Warrendale, PA, 2002, pp. 63–71.

B.C. De Cooman, J.G. Speer (2011) Fundamentals of Steel Product Physical Metallurgy, ASM International, Materials Park, OH, p. 392.

R.D. Lawson, D.K. Matlock, and G. Krauss: Fundamentals of Dual Phase Steels Symposium, TMS-AIME, Warrendale, PA, 1981, pp. 347–81.

Y.I. Son, Y.K. Lee, K.-T. Park, C.S. Lee, D. Hyuk Shin (2005) Acta Mater (53): 3125–34.

M. Calcagnotto, D. Ponge, E. Demir, and D. Raabe: Mater. Sci. Eng. A, 2010, vol. 527, pp. 2738–46.

U. Liedl, S. Traint, and E.A. Werner: Computat. Mater. Sci., 2002, vol. 25, pp. 122–28.

H. Fischmeister and B. Karlsson: Z. Für Metallkunde, 1977, vol. 68, pp. 311–27.

M. Dollar and S. Gorczyca: Metal Sci., 1983, vol. 17, pp. 671–79.

M.Y. Liu, B. Shi, C. Wang, S.K. Ji, X. Cai, and H.W. Song: Mater. Lett., 2002, vol. 57, pp. 2798–2802.

O. Maid: PhD Thesis, RWTH, Aachen University, Aachen, Germany, 1986.

W. Bleck and W. Mueschenborn: Thyssen Technische Berichte, 1984, no.1, pp. 24–32.

Z. Jiang, G. Zhenzhong, and J. Lian: Mater. Sci., 1995, vol. 190, pp. 55–64.

C.A.N. Lanzilotto and F.B. Pickering: Metal Sci., 1982, vol. 16, p. 371.

R. Song, D. Ponge, D. Raabe, and R. Kaspar: Acta Mater., 2005, vol. 53, pp. 845–58.

J.M. Rigsbee and P.J. Van der Arend: Dual-Phase HSLA Steels, Formable HSLA and Dual-Phase Steels, A.T. Davenport, ed., TMS-AIME, Warrendale, PA, 1979, pp. 56–86.

A.R. Marder: Metall. Trans. A, 1982, vol. 13, pp. 85–92.

R. Davies: Metall. Trans. A, 1978, vol. 9, pp. 671–79.

M.F. Ashby: Phil. Mag., 1970, vol. 21, pp. 399–424.

M.F. Ashby: Phil. Mag., 1966, vol. 14, pp. 1157–78.

Z. Jiang, J. Liu, and J. Lian: Acta Metall. Mater., 1992, vol. 40, pp. 1587–97.

R.M. Rodriguez and I. Gutierrez: Mater. Sci. Forum, 2003, vols. 426–432, pp. 4525–30.

V. Uthaisangsuk: PhD Thesis, RWTH, Aachen University, Aachen, Germany, 2009.

V. Uthaisangsuk, S. Muenstermann, U. Prahl, W. Bleck, H.-P. Schmitz, and T. Pretorius: Computat. Mater. Sci., 2011, vol. 50, pp. 1225–32.

C. Thomser, V. Uthaisangsuk, and W. Bleck: Steel Res. Int., 2009, vol. 80, pp. 582–87.

M. Calcagnotto, Y. Adachi, D. Ponge, and D. Raabe: Acta Mater., 2011, vol. 59, pp. 658–70.

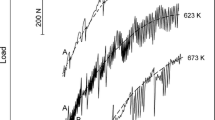

R. Kaspar and O. Pawelski: Materialprufung, 1989, vol. 31, p. 14.

O. Pawelski and R. Kaspar: Materialprufung, 1988, vol. 30, p. 357.

V.G. Kouznetsova: PhD Thesis, Technical University Eindhoven, Eindhoven, the Netherlands, 2002.

A. Ramazani, K. Mukherjee, U. Prahl, and W. Bleck: Comput. Mater. Sci., 2011, vol. 52, pp. 46–54.

Y. Bergström: Mater. Sci. Eng., 1970, vol. 5, pp. 193–200.

Y. Estrin and H. Mecking: Acta Metall., 1984, vol. 32, pp. 57–70.

O. Bouaziz and P. Buessler: La Revue De Metallurgie–CIT 99, 2002, pp. 71–77.

G. Reisner: VDI Fortschritt-Berichte, Reihe 18: Mechanik/Bruchmechanik, no. 214.

G. Piatti and P. Schiller: J. Nucl. Mater., 1986, vols. 141–143, pp. 417–26.

B.A. Bilby and J.W. Christian: J. Iron Steel Inst., 1961, vol. 197, pp. 122–31.

M.S. Wechsler, D.S. Lieberman, and T.A. Read: AIME Trans. JIM, 1953, vol. 197, pp. 1503–15.

T. Gladman and F.B. Pickering: Yield, Flow and Fracture of Polycrystals, T.N. Baker, ed., Applied Science Publishers Ltd., London, U.K., 1983, pp. 141–98.

W. Bleck: Material Characterisation, 1st ed., Verlag Mainz, Aachen, Germany, 2009.

F.B. Pickering: Constitution and Properties of Steels, R.W. Chan and F.B. Pickering, eds., VCH Verlasgesellschaft GmbH, Weinheim, Germany, 1992, pp. 41–94.

J. Kadkhodapour, S. Schmauder, D. Raabe, S. Ziaei-Rad, U. Weber, and M. Calcagnotto: Acta Mater., 2011, vol. 59, pp. 4387–94.

Acknowledgments

This research was carried out under project number MC2.07293 in the framework of the Research Program of the Materials Innovation Institute M2i (www.m2i.nl). The authors also wish to thank Dr. Marion Calcagnotto from Salzgitter Mannesmann Forschung GmbH for her tensile test data files and discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 5, 2011.

Rights and permissions

About this article

Cite this article

Ramazani, A., Mukherjee, K., Prahl, U. et al. Transformation-Induced, Geometrically Necessary, Dislocation-Based Flow Curve Modeling of Dual-Phase Steels: Effect of Grain Size. Metall Mater Trans A 43, 3850–3869 (2012). https://doi.org/10.1007/s11661-012-1196-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1196-3