Abstract

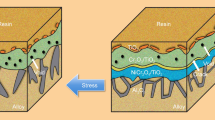

The precipitation behaviors of the topologically close-packed (TCP) phase in the Ru-free and Ru-containing single-crystal Ni-based superalloys have been investigated. All the TCP phases have been identified as the μ phase with large numbers of planar defects by using a scanning transmission electron microscope (STEM). The addition of 3 wt pct Ru effectively suppresses the nucleation of the μ phase because the addition of 3 wt pct Ru not only decreases the supersaturation of γ phase but also increases the elastic strain energy for the nucleation of the μ phase. Additionally, the addition of 3 wt pct Ru makes more Re enter the μ phase during its growth and the critical nucleus radius of the μ phase becomes larger. Therefore, it is found that the addition of 3 wt pct Ru decreases the growth rate of the μ phase.

Similar content being viewed by others

References

R.C. Reed: The Superalloys: Fundamentals and Applications, Cambridge University Press, Cambridge, U.K., 2006.

A. Sato, H. Harada, A.C. Yeh, K. Kawagishi, T. Kobayashi, Y. Koizumi, T. Yokokawa, and J.X. Zhang: Superalloys 2008, TMS, Warrendale, PA, 2008, pp. 131–38.

R. Darolia, D.F. Lahrman, R.D. Field, and R. Sisson: Superalloys 1988, TMS, Warrendale, PA, 1988, pp. 255–64.

C.M.F. Rae and R.C. Reed: Acta Mater., 2001, vol. 49, pp. 4113–25.

M. Simonetti and P. Caron: Mater. Sci. Eng. A, 1998, vol. 254, pp. 1–12.

R.C. Reed, D.C. Cox, and C.M.F. Rae: Mater. Sci. Eng. A, 2007, vol. 448, pp. 88–96.

Y. Koizumi, T. Kobayashi, T. Yokokawa, J. X. Zhang, M. Osawa, H. Harada, Y. Aoki, and M. Arai: Superalloys 2004, TMS, Warrendale, PA, 2004, pp. 35–43.

K. O’Hara, W. Walston, E. Ross, and R. Darolia: U.S. Patent No. 5,482,789, General Electric Company, Cincinnati, OH, 1996.

S. Walston, A. Cetel, R. MacKay, K. O’Hara, D. Duhl, and R. Dreshfield: Superalloys 2004, TMS, Warrendale, PA, 2004, pp. 15–24.

A.P. Ofori, C.J. Humphreys, S. Tin, and C.N. Jones: Superalloys 2004, TMS, Warrendale, PA, 2004, pp. 787–94.

A. Sato, H. Harada, T. Yokokawa, T. Murakumo, Y. Koizumi, T. Kobayashi, and H. Imai: Scripta Mater., 2006, vol. 54, pp. 1679–84.

R.A. Hobbs, L. Zhang, C.M.F. Rae, and S. Tin: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 1014–25.

J.Y. Chen, Q. Feng, and Z.Q. Sun: Scripta Mater., 2010, vol. 63, pp. 795–98.

W. Neumann, H. Kirmse, I. Häusler, A. Mogilatenko, C. Zheng, and W. Hetaba: Bull. Pol. Acad. Sci.: Tech. Sci., 2010, vol. 58, pp. 237–53.

P. Carvalho, H. Haarsma, B. Kooi, P. Bronsveld, and J.T.M. De Hosson: Acta Mater., 2000, vol. 48, pp. 2703–12.

P. Carvalho and J.T.M. De Hosson: Scripta Mater., 2001, vol. 45, pp. 333–40.

K. Hiraga, T. Yamamoto, and M. Hirabayashi: Trans. Jpn. Inst. Met., 1983, vol. 24, pp. 421–8.

J. Zhu and H. Ye: Scripta Metall. Mater., 1990, vol. 24, pp. 1861–66.

X.P. Tan, J.L. Liu, T. Jin, Z.Q. Hu, H.U. Hong, B.G. Choi, I.S. Kim, and C.Y. Jo: Mater. Sci. Eng. A, 2011, vol. 528, pp. 8381–88.

K.Y. Cheng: PhD Thesis, Institute of Metal Research, Chinese Academy of Sciences, Shenyang, China, 2009.

A.K. Sinha: Topologically Close-Packed Structures of Transition Metal Alloys, Pergamon Press, Oxford, U.K., 1972.

D.A. Porter and K.E. Easterling: Phase Transformations in Metals and Alloys, 2nd ed., Chapman & Hall, New York, NY, 1992.

M.S.A. Karunaratne and R.C. Reed: Acta Mater., 2003, vol. 51, pp. 2905–19.

Acknowledgments

This work was financially supported by the National Basic Research Program (973 Program) of China under Grant 2010CB631200 (2010CB631206) and by the National Natural Science Foundation of China (NSFC) under grants 50931004 and U1037601. The authors are grateful for the support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 13, 2011.

Rights and permissions

About this article

Cite this article

Tan, X., Liu, J., Jin, T. et al. Effect of Ruthenium on Precipitation Behavior of the Topologically Close-Packed Phase in a Single-Crystal Ni-Based Superalloy During High-Temperature Exposure. Metall Mater Trans A 43, 3608–3614 (2012). https://doi.org/10.1007/s11661-012-1163-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1163-z