Abstract

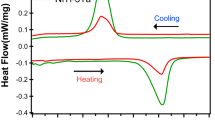

Ni-49Ti and Ni-30Pt-50Ti (nominal at. pct) shape memory alloys (SMAs) were isothermally oxidized in air over the temperature range of 773 K to 1173 K (500 °C to 900 °C) for 100 hours. The oxidation kinetics, presented in detail in a companion study, show ~4 times reduction in oxidation rate due to Pt.[1] The microstructure, composition, and phase content of the scales and depletion zones were determined by scanning electron microscopy (SEM), energy dispersive spectroscopy (EDS), and X-ray diffraction (XRD). A relatively pure TiO2 rutile structure was identified as the predominant scale surface feature, typified by a distinct highly striated and faceted crystal morphology, with crystal size proportional to oxidation temperature. The complex layered structure beneath these crystals was characterized by semiquantitative XRD of serial/taper polished sections and SEM/EDS of cross sections for samples oxidized at 973 K (700 °C). In general, graded mixtures of TiO2, NiTiO3, NiO, Ni(Ti), or Pt(Ni) metallic dispersoids, and continuous Ni3Ti or Pt-rich metal depletion zones, were observed from the gas surface to the substrate interior. Overall, substantial depletion of Ti occurred due to the formation of predominantly TiO2 scales. It is proposed that the Ni-30Pt-50Ti alloy oxidized more slowly than the binary Ni-49Ti alloy by decreasing oxygen and titanium diffusion through the thin Pt-rich layer.

Similar content being viewed by others

References

J.L. Smialek, D.L. Humphrey, and R.D. Noebe: Oxid. Met., 2010, vol. 74, pp. 125–44.

W. Tang: Metall. Mater. Trans. A, 1997, vol. 28A, pp. 537–44.

J. Ma, I. Karaman, and R.D. Noebe: Int. Mater. Rev., 2010, vol. 55, pp. 257–315.

R. Noebe, D. Gaydosh, S. Padula, A. Garg, T. Biles, and M. Nathal: Proc. SPIE, 2005, vol. 5761, pp. 364–75.

S. Padula, G. Bigelow, R. Noebe, and D. Gaydosh, and A. Garg: SMST 2006: Proc. Int. Conf. on Shape Memory and Superelastic Technologies, ASM INTERNATIONAL, Metals Park, OH, 2008, pp. 787–802.

O. Rios, R.D. Noebe, T. Biles, A. Garg, A. Palczer, D. Scheiman, H.J. Seifert, and M. Kaufman: Proc. SPIE, 2005, vol. 5761, pp. 376–87.

E.T.F. Chau, C.M. Friend, D.M. Allen, J. Hora, and J.R. Webster: Mater. Sci. Eng. A, 2006, vols. 438–440, pp. 589–92.

J.A. DeCastro, K.J. Melcher, and R.D. Noebe: Proc. 41st Joint Propulsion Conf., American Institute of Aeronautics and Astronautics, Reston, VA, 2005, paper no. AIAA-2005-3988.

F.T. Calkins and J.H. Mabe: J. Mech. Des., 2010, vol. 132, pp. 111012-1–111012-7.

D. Stoeckel: Mater. Des., 1990, vol. 11, pp. 302–07.

J.V. Humbeeck: Mater. Sci. Eng., A, 1999, vols. 273–275, pp. 134–48.

T. Duerig, A. Pelton, and D. Stockel: Mater. Sci. Eng. A, 1999, vols. 273–275, pp. 149–60.

P. Filip, J. Lausmaa, J. Musialek, and K. Manzanec: Biomaterials, 2001, vol. 22, pp. 2131–38.

C.L. Chu, T. Hu, S.L. Wu, Y.S. Dong, L.H. Yin, Y.P. Pu, P.H. Lin, C.Y. Cung, K.W.K. Yeung, and P.K. Chu: Acta Biomater., 2007, vol. 3, pp. 795–806.

B. Lin, K. Gall, H.J. Maier, and R. Waldron: Acta Biomater., 2009, vol. 5, pp. 795–806.

G. Mani, M.D. Feldman, D. Patel, and C.M. Agrawal: Biomaterials, 2007, vol. 28, pp. 1689–1710.

J.L. Smialek, D.L. Humphrey, and R.D. Noebe: Oxidation Kinetics of a NiTiPt High Temperature Shape Memory Alloy, NASA/TM-2007-214697, NASA, Washington, DC, 2007.

T. Satow, T. Isano, and T. Honma: J. Jpn. Inst. Met., 1974, vol. 38, pp. 242–46.

C.M. Chan, S. Trigwell, and T.W. Duerig: Surf. Interface Anal., 1990, vol. 5, pp. 349–54.

C.L. Chu, S.K. Wu, and Y.C. Yen: Mater. Sci. Eng., A, 1996, vol. 216, pp. 193–200.

G.S. Firstov, R.G. Vitchev, H. Kumar, B. Blanpain, and J. Van Humbeeck: Biomaterials, 2002, vol. 23, pp. 4863–71.

L. Zhu, J.M. Fino, and A. Pelton: SMST 2003, Proc. Int. Conf. on Shape Memory and Superelastic Technologies, ASM INTERNATIONAL, Metals Park, OH., 2003, pp. 357–66.

D. Vojtěch, P. Novák, M. Novák, L. Jaska, T. Fabián, J. Maixner, and V. Machovič: Intermetallics, 2008, vol. 16, pp. 424–31.

C.H. Xu, X.Q. Ma, S.Q. Shi, and C.H. Woo: Mater. Sci. Eng., A, 2004, vol. 371, pp. 45–50.

Q. Tian and J. Wu: Mater. Sci. Forum, 2002, vols. 394–395, pp. 455–58.

Q. Tian, J. Chen, Y. Chen, and J. Wu: Z. Metallkd., 2003, vol. 94, pp. 36–40.

K.-N. Lin and S.-K. Wu: Oxid. Met., 2009, vol. 71, pp. 187–200.

J.L. Smialek, A. Garg, R.B. Rogers, and R.D. Noebe: Oxide Scales Formed on NiTi and NiPtTi Shape Memory Alloys, NASA/TM–2011-217096, NASA, Washington, DC, 2011.

K. Otsuka and X. Ren: Prog. Mater Sci., 2005, vol. 50, pp. 511–678.

Binary Alloy Phase Diagrams, 2nd ed., T.B. Massalski, H. Okamoto, P.R. Subramanian, and L. Kacprzak, eds., ASM INTERNATIONAL, Metals Park, OH, 1990, vol. 3, p. 2874.

K. Tello, S. Cochran, J. Nuechterlein, K. Roman, D. Drake, H. Rosin, A. Garg, R. Noebe, and M.J. Kaufman: unpublished research, Colorado School of Mines, 2011.

J.L. Smialek, M.A. Gedwell, and P.K. Brindley: Scripta Metall. Mater., 1990, vol. 24, pp. 1291–96.

C.L. Zeng, M.C. Li, G.Q. Liu, and W.T. Wu: Oxid. Met., 2002, vol. 58, pp. 171–84.

Y.-J. Park, H.-J. Song, I. Kim, and H.-S. Yang: J. Mater. Med., 2007, vol. 18, pp. 565–75.

Acknowledgments

The authors thank R. Mattingly for his expert assistance with XRD data acquisition and analysis, enabling the success of the serial/taper section phase profiling studies. This work was funded by the NASA Fundamental Aeronautics Program, Supersonic Project (Dr. Dale Hopkins, API).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 28, 2011.

Rights and permissions

About this article

Cite this article

Smialek, J.L., Garg, A., Rogers, R.B. et al. Oxide Scales Formed on NiTi and NiPtTi Shape Memory Alloys. Metall Mater Trans A 43, 2325–2341 (2012). https://doi.org/10.1007/s11661-011-1036-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-1036-x