Abstract

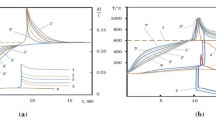

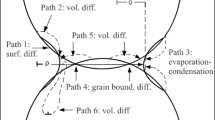

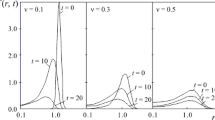

The effect of addition of copper on the sintering of a W powder was systematically investigated by the analysis of dilatometric experiments on W and W-Cu compacts prepared with submicrometric powders. A pure W powder compact and a W-10 wt pct Cu powder compact with the same packing fraction of W particles were first studied, in order to analyze the effect of copper at fixed microstructure of the solid W particle packing. A more systematic set of experiments with different copper contents and W particle sizes was also qualitatively analyzed. A phenomenological model of sintering was developed and fitted in order to extrapolate the effect of copper content on sintering kinetics at fixed microstructure of the W particle skeleton. An interpretation of the sintering mechanisms was then proposed. Sintering of a W-Cu powder compact is the result of solid-state sintering of the W skeleton, enhanced by the capillary forces exerted by copper, with the superimposition of a particle rearrangement step after copper melting.

Similar content being viewed by others

References

G. Pintsuk, S.E. Brunings, J.E. Doring, J. Linke, I. Smid, and L. Xue: Fus. Eng. Des., 2003, vol. 8, pp. 237–40.

Y. Ling, X. Bai, and G. Changchun: Mater. Sci. For., 2003, vols. 423–425, pp. 49–54.

R. Mitteau, J.M. Missiaen, P. Brustolin, O. Ozer, A. Durocher, C. Ruset, C.P. Lungu, X. Courtois, C. Dominicy, H. Maier, C. Grisolia, G. Piazza, and P. Chappuis: Fus. Eng. Des., 2007, vol. 82, pp. 1700–05.

J.S. Lee, T.H. Kim, and T.G. Kang: Proc. Powder Metall. World Congr., Les Edition de Physique, Paris, 1994, pp. 1501–04.

J.L. Johnson and R.M. German: Metall. Mater. Trans. B, 1996, vol. 27B, pp. 901–09.

F. Doré, C.H. Allibert, R. Baccino, and F. Lartigue: Proc. 15th Int. Plansee Seminar, Plansee AG, Plansee, Austria, 2001, pp. 81–93.

S.S. Ryu, Y.D. Kim, and I.H. Moon: J. Alloys Compd., 2002, vol. 335, pp. 233–40.

F.A. Da Costa, A.G.P. Da Silva, and U. Umbelino Gomes: Powder Technol., 2003, vol. 134, pp. 123–32.

D.G. Kim, G.S. Kim, M.J. Suk, S.T. Oh, and Y.D. Kim: Scripta Mater., 2004, vol. 51, pp. 677–81.

S.-H. Hong, B.-K. Kim, and Z. Munir: Mater. Sci. Eng. A, 2005, vol. 405, pp. 325–32.

J. Cheng, P. Song, Y. Gong, Y. Cai, and Y. Xia: Mater. Sci. Eng. A, 2008, vol. 488, pp. 453–57.

J.J. Raharijaona and J.M. Missiaen: Int. J. Refractory Metals Hard Mater., 2010, vol. 28, pp. 388–93.

W. D. Kingery: J. Appl. Phys., 1959, vol. 30, pp. 301–06.

R.M. German: Liquid Phase Sintering, Plenum Press, New York, NY, 1985.

R.M. German: Powder Metallurgy Science, Metal Powder Industry Federation, Princeton, NJ, 1994.

J.-M. Missiaen: Mater. Sci. Eng. A, 2008, vol. 475, pp. 2–11.

J. Johnson, J. Brezovsky, and R. German: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 1557–65.

W.J. Huppmann and H. Riegger: Acta Metall. Mater., 1975, vol. 23, pp. 965–71.

W.J. Huppmann, H. Riegger, W.A. Kaysser, V. Smolej, and S. Pejovnik: Z. Metallkd., 1979, vol. 70, pp. 707–13.

S.-M. Lee, J.-M. Chaix, C.L. Martin, C.H. Allibert, and S.-J.L. Kang: Met. Mater., 1999, vol. 5, pp. 197–203.

V.V. Panichkina, M.M. Sirotiuk, and V.V. Skorokhod: Porosh. Met., 1982, vol. 234, p. 27.

F. Doré, C.L. Martin, and C.H. Allibert: Mater. Sci. Eng. A, 2004, vol. 383, pp. 390–98.

E.N. Hodkin, M.G. Nicholas, and D.M. Poole: J. Less-Common Met., 1970, vol. 20, pp. 93–103.

A. Upadhyaya and R.M. German: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2631–38.

J. Johnson, J. Brezovsky, and R. German: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 2807–14.

V. Bounhoure, J.M. Missiaen, S. Lay, and E. Pauty: J. Am. Cer. Soc., 2009, vol. 92, pp. 1396–1402.

O. Gillia and D. Bouvard: Mater. Sci. Eng. A, 2000, vol. 279, pp. 185–91.

Acknowledgments

This work was carried out with the support of the European Fusion Development Agreement (EFDA) and the European Union under the Association EURATOM/CEA entity. The authors also thank the Eurotungstene Metal Powders–French Company for material supply and technical support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 11, 2010.

Rights and permissions

About this article

Cite this article

Raharijaona, JJ., Missiaen, JM. & Bouvard, D. A Phenomenological Analysis of Sintering Mechanisms of W-Cu from the Effect of Copper Content on Densification Kinetics. Metall Mater Trans A 42, 2411–2419 (2011). https://doi.org/10.1007/s11661-011-0615-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-0615-1