Abstract

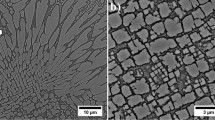

The compositional and microstructural evolution of different generations of precipitates of the ordered γ′ phase during the continuous cooling, followed by isothermal aging, of a commercial nickel-base superalloy, Rene 88DT, has been characterized by three-dimensional atom probe (3DAP) tomography coupled with energy-filtered transmission electron microscopy (EFTEM) studies. After solutionizing in the single γ-phase field, during continuous cooling at a relatively slow rate (~24 °C/min), the first-generation primary γ′ precipitates, forming at relatively higher temperatures, exhibit near-equilibrium compositions, while the smaller-scale secondary γ′ precipitates, forming at lower temperatures, exhibit nonequilibrium compositions often containing an excess of Co and Cr while being depleted in Al and Ti content. The compositions of the γ matrix near these precipitates also exhibit similar trends, with the composition being closer to equilibrium near the primary precipitates as compared to the secondary precipitates. Subsequent isothermal aging at 760 °C leads to coarsening of the primary γ′ precipitates without affecting their composition significantly. In contrast, the composition of the secondary γ′ precipitates is driven toward equilibrium during the isothermal aging process.

Similar content being viewed by others

Notes

Simplex Electropointer is a trademark of Simplex Scientific, Middleton, WI.

Nova Nanolab 200 is a trademark of FEI, Hillsboro, OR.

LEAP 3000 is a trademark of Imago Scientific Instruments, Madison, WI.

Duo Mill is a trademark of Gatan Inc., Pleasanton, CA.

1010 Ion Mill is a trademark of Fischione Instruments, Export, PA.

Tecnai F20 is a trademark of FEI, Hillsboro, OR.

References

R.J. Mitchell and M. Preuss: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 615–27.

D.D. Krueger, R.D. Kissinger, R.G. Menzies, and C.S. Wukusick: U.S. Patent 4,957,567, 1990.

D.D. Krueger, R.D. Kissinger, and R.G. Menzies: in Superalloys 1992, S.D. Antolovich, R.W. Stusrud, R.A. Mackay, D.L. Anton, T. Khan, R.D. Kissinger, and D.L. Klarstrom, eds., TMS-AIME, Warrendale, PA, 1992, pp. 277–86.

S.T. Wlodek, M. Kelly, and D.A. Alden: in Superalloys 1996, R.D. Kissinger, D.J. Deye, D.L. Anton, A.D. Cetel, M.V. Nathal, T.M. Pollock, and D.A. Woodford, eds., TMS, Warrendale, PA, 1996, pp. 129–36.

S.S. Babu, M.K. Miller, J.M. Vitek, and S.A. David: Acta Mater., 2001, vol. 49, pp. 4149–60.

J.Y. Hwang, R. Banerjee, J. Tiley, R. Srinivasan, G.B. Viswanathan, and H.L. Fraser: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 24–35.

P.M. Sarosi, B. Wang, J.P. Simmons, Y. Wang, and M.J. Mills: Scripta Mater., 2007, vol. 57, pp. 767–70.

Y.H. Wen, J.P. Simmons, C. Shen, C. Woodword, and Y. Wang: Acta Mater., 2003, vol. 51, pp. 1123–32.

Y.H. Wen, B. Wang, J.P. Simmons, and Y. Wang: Acta Mater., 2006, vol. 54, pp. 2087–99.

D.N. Seidman, C.K. Sudbrack, and K.E. Yoon: JOM, 2006, vol. 58 (12), pp. 34–39.

M.K. Miller: Micron, 2001, vol. 32, pp. 757–64.

D. Blavette, E. Cadel, and B. Deconihout: Mater. Charact., 2000, vol. 44, pp. 133–57.

C.K. Sudbrack, K.E. Yoon, R.D. Noebe, and D.N. Seidman: Acta Mater., 2006, vol. 54, pp. 3199–3210.

Z. Mao, C.K. Sudbrack, K.E. Yoon, G. Martin, and D.N. Seidman: Nat. Mater., 2007, vol. 6, pp. 210–16.

C.K. Sudbrack, R.D. Noebe, and D.N. Seidman: Acta Mater., 2007, vol. 55. pp. 119–30.

P.M. Sarosi, G.B. Viswanathan, D. Whitis, and M.J. Mills: Ultramicroscopy, 2005, vol. 103, pp. 83–93.

J. Tiley, G.B. Viswanathan, R. Srinivasan, R. Banerjee, and H.L. Fraser: Acta Mater., 2009, vol. 57, pp. 2538–49.

J.W. Littles, Jr., R.G. Pettit, J.J. Schirra, B.A. Cowles, R.A. Holmes, S.M. Russ, H. Rosenberger, and J.M. Larsen: Materials Damage Prognosis, TMS, Warrendale, PA, 2005, pp. 23–29.

K. Thompson, D. Lawrence, D.J. Larson, J.D. Olson, T.F. Kelly, and B. Gorman: Ultramicroscopy, 2007, vol. 107, pp. 131–39.

J.Y. Hwang, S. Nag, A.R.P. Singh, R. Srinivasan, J. Tiley, H.L. Fraser, and R. Banerjee: Scripta Mater., 2009, vol. 61, pp. 92–95.

Smithells Metals Reference Book, 7th ed., E.A. Brandes and G.B. Brook, eds., Butterworth-Heinemann Ltd., Oxford, UK, 1992, ch. 13, pp. 1–118.

Acknowledgments

The authors acknowledge the United States Air Force Research Laboratory (AFRL ISES contract, Contract No. FA8650-08-C-5226) and the United States Air Force Office of Scientific Research (AFOSR Grant No. FA9550-06-1-0193) for providing financial support for this study. In addition, the authors also gratefully acknowledge the CART at the University of North Texas (Denton, TX) and the CAMM at The Ohio State University (Columbus, OH) for access to the experimental facilities used for this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 7, 2009.

Rights and permissions

About this article

Cite this article

Hwang, J., Nag, S., Singh, A. et al. Compositional Variations between Different Generations of γ′ Precipitates Forming during Continuous Cooling of a Commercial Nickel-Base Superalloy. Metall Mater Trans A 40, 3059–3068 (2009). https://doi.org/10.1007/s11661-009-0075-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-0075-z