Abstract

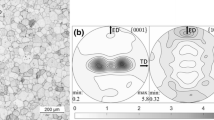

The effects of crystallographic texture and precipitate distribution on macroscopic anisotropy in aluminum alloys were investigated. In order to simultaneously consider the effects of crystallographic texture and precipitate distribution on macroscopic anisotropy, predictions of plastic properties were carried out using an anisotropic yield function based on the material texture and a combined isotropic-kinematic hardening rule. The input to the model was a single stress-strain curve, the crystallographic texture, and the precipitate volume fraction, shape, and habit planes. It was shown that the kinematic hardening rule, which expresses a translation of the yield surface in stress space, was a function of all the parameters describing the precipitate distribution. The model was applied to the case of an extruded and recrystallized binary Al-3 wt pct Cu alloy deformed in uniaxial compression in different directions. Excellent agreement was observed between the experimental and predicted yield stress anisotropy and the specimen cross section shape anisotropy. Gaussian distributions of grain orientations around ideal texture components typical of aluminum alloys were generated using computer simulations. These textures were combined with the isotropic-kinematic hardening rule determined for the Al-3 wt pct Cu binary alloy to theoretically assess the influence of precipitates on the r-value (the width-to-thickness plastic strain ratio in uniaxial tension) and yield stress anisotropy for aluminum sheets. It was shown that, for these textures, the precipitate distribution had the effect of reducing plastic anisotropy, in agreement with the trends generally observed in practice.

Similar content being viewed by others

References

F. Barlat: Mater. Sci. Eng., 1987, vol. 95, pp. 15–29.

S.-H. Choi, J.-H. Cho, F. Barlat, K. Chung, J.W. Kwon, and K.H. Oh: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 377–86.

K.K. Mathur, P.R. Dawson, and U.F. Kocks: Mech. Mater., 1990, vol. 10, pp. 183–202.

A.D. Rollett, D. Juul Jensen, and M.G. Stout: Proc. 13th Ris. Int. Symp. on Materials Science, S.I. Anderson et al., eds., Riso National Laboratory, Roskilde, Denmark, 1992, pp. 93–109.

F. Barlat and J. Liu: Mater. Sci. Eng., 1998, vol. A257, pp. 47–61

S.-H. Choi and F. Barlat: Proc. 4th Int. Conf. on Constitutive Laws for Engineering Materials, Troy, NY, July 27–30, 1999, R.C. Picu and E. Krempl, eds., Rensselaer Polytechnique Institute, Troy, NY, 1999, pp. 217–20.

H. Hargarter, M.T. Lyttle, and E.A. Starke: Mater. Sci. Eng., 1998, vol. A257, p. 87.

S.-H. Choi, J.C. Brem, F. Barlat, and K.H. Oh: Proc. ICOTOM 12, 1999, J.A. Szpunar, ed., NRC Research Press, Ottowa, 1999, pp. 569–74.

S.-H. Choi and F. Barlat: Scripta Mater., 1999, vol. 41, pp. 981–86.

V. Gerold: in Dislocations in Solids, F.R.N. Nabarro, ed., North-Holland Publishing Company, Amsterdam, 1979, vol. 4, pp. 221–60.

J.W. Martin: Micromechanisms in Particle-Hardened Alloys, Cambridge University Press, Cambridge, United Kingdom, 1980.

W.F. Hosford and R.H. Zeisoft: Metall. Trans., 1972, vol. 3, pp. 113–21.

G.I. Taylor: J. Inst. Met., 1938, vol. 62, pp. 307–24.

J.W.F. Bishop and R. Hill: Phil. Mag., 1951, vol. 42, pp. 414–27.

P. Bate, W.T. Roberts, and D.V. Wilson: Acta Metall., 1981, vol. 29, pp. 1797–1814.

D.V. Wilson: Acta Metall., 1965, vol. 13, pp. 807–14.

J.D. Eshelby: R. Soc. London, 1957, vol. A241, pp. 376–96.

R.D. Doherty, D.A. Hughes, F.J. Humphreys, J.J. Jonas, D. Juul Jensen, M.E. Kassner, W.E. King, T.R. McNelley, H.J. McQueen, and A.D. Rollett: Mater. Sci. Eng., 1997, vol. A238, pp. 219–74.

M.T. Pérez-Prado, T.R. McNelley, O.A. Ruano, and G. González-Doncel: Metall. Mater. Trans., A 1998, vol. A29A, pp. 485–92.

S. Matthies: Phys. Status Solid, 1980, vol. 101, pp. 111–15.

S. Matthies and F. Wagner: Phys. Status Solid, 1981, vol. 107, 591–601.

H.J. Bunge: Texture Analysis in Material Science, Butterworth and Co., London, 1982.

F. Barlat, Y. Maeda, K. Chung, M. Yanagawa, J.C. Brem, Y. Hayashida, D.J. Lege, K. Matsui, S.J. Murtha, S. Hattori, R.C. Becker, and S. Makosey: J. Mech. Phys. Solids, 1997, vol. 45, pp. 1727–63.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Choi, S.H., Barlat, F. & Liu, J. Effect of precipitates on plastic anisotropy for polycrystalline aluminum alloys. Metall Mater Trans A 32, 2239–2247 (2001). https://doi.org/10.1007/s11661-001-0199-2

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0199-2