Abstract

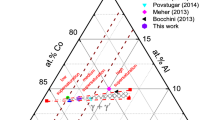

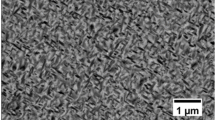

Discontinuous coarsening (DC) of the primary lamellar structure (PLS) occurring at lamellar colony boundaries (LCBs) and in surface layers of various Ti-(40 to 45) at. pct Al binary and Ti-46 at. pct Al-X (X=Si and C) ternary alloys was systematically investigated by using optical microscopy and scanning and transmission electron microscopy. The compositions of the α 2 and γ phases in the primary lamellar structure were estimated based on the weight fractions of the two phases, determined by X-ray diffraction. When the solution-treated Ti-(40 to 45) at. pct Al binary alloys were subsequently soaked at 1000 °C, the primary lamellae in the Ti-40 at. pct Al alloy were the most stable, while those in the Ti-44 at. pct Al were the most unstable. Both the thermodynamic analysis and experimental results confirm that the driving force of the coarsening is mainly derived from the reduction of the chemical free energy (i.e., out-of-equilibrium chemical composition) and the interfacial energy of primary lamellae, whereas the coarsening resistance is mainly from the increase of the elastic strain energy of lamellar interfaces and the surrounding during coarsening. It is found that Si has an exceptional ability to hinder the coarsening of the primary lamellar structure at high temperatures, but the precise mechanism for this improvement is uncertain now. Based on this study, a proposal is finally addressed to improve the thermal stability of the primary lamellar structure of titanium aluminides.

Similar content being viewed by others

Abbreviations

- DC:

-

discontinuous coarsening

- EM:

-

eutectic microstructure containing the Ti5(Al,Si)3 phase in the Ti-Al-Si system

- PLS:

-

primary lamellar structure

- L:

-

lamellae

- LCB:

-

lamellar colony boundary

- SL:

-

surface layer of one specimen

- ΔF :

-

driving force of discontinuous coarsening

- ΔG I :

-

reduction of interfacial energy after the coarsening

- ΔG C :

-

chemical free energy loss after the coarsening, i.e., difference of ΔG /Total m and ΔG /PLS m at a given temperature

- ΔG /Total m :

-

chemical free energy loss from a superstaturated α 2 matrix to the equilibrium α 2 and γ phases at a given temperature

- ΔG /PLS m :

-

chemical free energy loss from a supersaturated α 2 matrix to the metastable α 2 and γ phases (primary lamellar structure) at a given temperature

- ΔG S :

-

strain energy stored in surface layer due to specimen preparation

- ΔF S :

-

driving force of the coarsening in surface layer

- ΔG R :

-

discontinuous coarsening resistance

- ΔG ES :

-

increase of elastic strain energy during the coarsening

- ΔG B :

-

increase of grain boundary energy during the coarsening associated with the increase of DC cell boundary area

References

K.S. Chan and Y.-W. Kim: in Microstructure/Property Relationships in Titanium Aluminides and Alloys, Y.-W. Kim and R.R. Boyer, eds., TMS, Warrendale, PA, 1991, pp. 179–96.

K.S. Chan, J. Onstott, and K.S. Kumar: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 71–80.

G. Frommeyer, W. Wunderlich, T. Kremser, and Z.G. Liu: Mater. Sci. Eng., 1992, vol. A152, pp. 166–72.

Y.-W. Kim: JOM, 1994, vol. 46, pp. 30–40.

D.S. Shih, S.-C. Huang, G.K. Scarr, H. Jiang, and J.C. Chestnutt: in Microstructure/Property Relationships in Titanium Aluminides and Alloys, Y.-W. Kim and R.R. Boyer, eds., TMS, Warrendale, PA, 1991, pp. 135–48.

J. Campbell, K.T. Venkateswara Rao, and R.O. Ritchie: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 563–77.

M.F. Bartholomensz and J.A. Wert: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 2161–71.

Y.-W. Kim: Acta Metall. Mater., 1992, vol. 40, pp. 1121–34.

A. Denquin and S. Naka: Acta Mater., 1996, vol. 44, pp. 343–65.

S.A. Jones and M.J. Kaufman: Acta Metall. Mater., 1993, vol. 41, pp. 387–98.

P. Pouly, M.J. Hua, C.I. Garcia, and A.J. DeArdo: Scripta Metall. Mater., 1993, vol. 29, pp. 1529–34.

S.I. Kardashova, A.Y. Lozovoi, and I.M. Razumovskii: Acta Metall. Mater., 1994, vol. 42, pp. 3341–48.

D.S. Shong and Y.-W. Kim: Scripta Metall. Mater., 1989, vol. 23, pp. 257–61.

Y. Yamabe, N. Honjo, and M. Kikuchi: Proc. Int. Symp. on Intermetallic Compounds, Structure and Mechanical Properties (JIMIS-6), O. Izumi, ed., JIM, Sendai, 1991, pp. 821–24.

G.W. Qin, J.J. Wang, and S.M. Hao: Intermetallics, 1999, vol. 7, pp. 1–4.

G.W. Qin, S.M. Hao, and D. Song: Acta Metall. Sinica, 1998, vol. 34, pp. 1279–85 (in Chinese).

M. Oehring, P.J. Ennis, F. Appel, and R. Wagner: in High-Temperature Ordered Intermetallic Alloys VII, Materials Research Society Symposia Proceedings, C.C. Koch, C.T. Liu, N.S. Stoloffad, and A. Wanner, eds., MRS, Pittsburgh, PA, 1997, pp. 257–62.

J.N. Wang and T.G. Nieh: Acta Mater., 1998, vol. 46, pp. 1887–1901.

J.Y. Jung and J.K. Park: Acta Mater., 1998, vol. 46, pp. 4123–30.

S. Mitao and L.A. Bendersky: Acta Mater., 1997, vol. 45, pp. 4475–89.

G.W. Qin and S.M. Hao: Scripta Mater., 1997, vol. 37, pp. 937–42.

D. Hu, A.B. Godfrey, and M. Lorreto: Intermetallics, 1998, vol. 6, pp. 413–17.

D.Y. Seo, T.R. Bieler, S.U. An, and D.E. Larsen: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 89–98.

R.V. Ramanujan, P.J. Maziasz, and C.T. Liu: Acta Mater., 1996, vol. 44, pp. 2611–42.

S.-C. Huang, D.W. Mckee, D.S. Shih, and J.C. Chestnutt: in Intermetallic Compounds—Structure and Mechanical Properties, O. Izumi, ed., JIM, Sendai, 1991, pp. 367–70.

H.S. Park, S.K. Hwang, C.M. Lee, Y.C. Yoo, S.W. Nam, and N.J. Kim: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 251–59.

R.V. Ramanujan: Acta Metall. Mater., 1994, vol. 42, pp. 2775–81.

C. McCullough, J.J. Valencia, C.G. Levi, and R. Mehrabian: Acta Metall. Mater., 1989, vol. 37, pp. 1321–36.

Y. Umakoshi, T. Nakano, and T. Yamane: Mater. Sci. Eng. A, 1992, vol. A152, pp. 81–88.

J.D. Livingston and J.W. Cahn: Acta Metall., 1974, vol. 22, pp. 495–503.

M. Kikuchi and Y. Yamabe: Proc. of Int. Symp. on Intermetallic Compounds, Structure and Mechanical Properties (JIMIS-6), O. Izumi, ed., JIM, Sendai, 1991, pp. 815–88.

J.Y. Jung and J.K. Park: Phil. Mag. A, 2000, vol. 80, pp. 1127–38.

J.T. Li, Y.P. Zong, and S.M. Hao: J. Mater. Sci. Technol., 1999, vol. 15, pp. 58–74.

T. Noda, M. Okake, S. Isobe, and M. Sayashi: Mater. Sci. Eng. A, 1995, vols. A192–A193, pp. 774–79.

D.R. Johnson, H. Inui, and M. Yamaguchi: Acta Mater., 1996, vol. 44, pp. 2523–35.

S. Mitao and L.A. Bendersky: Proc. Int. Conf. on Solid-Solid Phase Transformations ’99 (JIMIC-3), M. Koiwa, K. Otsuka, and T. Miyazaki, eds., JIM, Kyoto, 1999, pp. 585–88.

A.T. Dinsdale: CALPHAD, 1991, vol. 15, pp. 317–425.

U.R. Kattner and W.J. Boettinger: Mater. Sci. Eng. A, 1992, vol. A152, pp. 9–17.

J.T. Li, M. Jiang, and S.M. Hao: J. Northeastern University (Natural Science Version), 1998, vol. 19, pp. 1–6.

U.R. Kattner, J.C. Lin, and Y.A. Chang: Metall. Mater. Trans. A, 1992, vol. 23A, pp. 2081–90.

H.A. Lipsitt: in Titanium Aluminides—an Overview, High Temperature Ordered Intermetallic Alloys, Materials Research Society Symposia Proceedings, MRS, Pittsburgh, PA, 1985, vol. 39, pp. 351–62.

F.R.N. Nabarro: Proc. Phys. Soc., 1940, vol. 52, pp. 90–104.

P. Wang and V.K. Vasudevan: Scripta Metall., 1992, vol. 27, pp. 89–94.

H. Tian, Z. Huang, C. Chen, and J. Lin: Acta Mater. Sinica, 1994, vol. A30, pp. 117–22 (in Chinese).

W.B. Lee, H.S. Yang, and A.K. Mukherjee: Mater. Sci. Eng. A, 1995, vols. A192–A193, pp. 733–40.

F.Y. Hau, G.X. Wang, and H.J. Klaar: Scripta Metall. Mater., 1995, vol. 33, pp. 597–601.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Qin, G.W., Oikawa, K., Sun, Z.M. et al. Discontinuous coarsening of the lamellar structure of γ-TiAl-based intermetallic alloys and its control. Metall Mater Trans A 32, 1927–1938 (2001). https://doi.org/10.1007/s11661-001-0005-1

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0005-1