Abstract

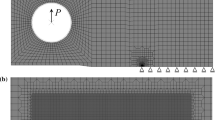

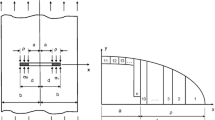

This article reviews expressions to quantify the thermal creep and fatigue lifetime for four copper alloys: Cu-Ag-P, Cu-Cr-Zr, Cu-Ni-Be, and Cu-Al2O3. These property models are needed to simulate the mechanical behavior of structures with copper components, which are subjected to high heat-flux and fatigue loading conditions, such as molds for the continuous casting of steel and the first wall in a fusion reactor. Then, measurements of four-point bending fatigue tests were conducted on two-layered specimens of copper alloy and stainless steel, and thermal ratchetting behavior was observed at 250 °C. The test specimens were modeled with a two-dimensional elastic-plastic-creep finite-element model using the ABAQUS software. To match the measurements, a primary thermal-creep law was developed for Cu-0.28 pct Al2O3 for stress levels up to 500 MPa and strain rates from 10−8 to 10−2 s−1. Specifically, \(\dot \varepsilon \)(s−1)=1.43×1010 exp (−197,000/8.31 T(K)) (σ(MPa))2.5 (t(s))−0.9.

Similar content being viewed by others

References

B.G. Thomas: “Effect of Copper Properties on Thermal Distortion of Continuous Slab Casting Molds,” University of Illinois at Urbana-Champaign, Urbana, IL, Report to Brush Wellman, Cleveland, OH; August 26, 1993.

B.G. Thomas, G. Li, A. Moitra, and D. Habing: ISS Trans., 1998, vol. 25(10), pp. 125–43.

J.O. Ratka and W.D. Spiegelberg: IEEE Trans. Magn., 1994, vol. 30(4), pp. 1859–62.

T.G. O’Connor and J.A. Dantzig: Metall. Mater. Trans. B, 1994, vol. 25B, pp. 443–57.

S.J. Zinkle and S.A. Fabritsev: Atomic and Plasma-Material Interaction Data for Fusion, December 1994, vol. 5, pp. 163–191.

J.F. Stubbins, D.C. Drockelman, P. Kurath, K.D. Leedy, G. Li, J.L. McAfee, G. D. Morgan, K.T. Stattery, B.G. Thomas, and G.W. Willy: Report No. ITER/US/95/IV-BL-20, Final Report of U.S. ITER Task T8 (CY 1995), University of Illinois at Urbana-Champaign, Urbana, IL, Dec. 1995.

P. Fenici, D.J. Boerman, G.P. Tartaglia, and J.D. Elen: J. Nucl. Mater., 1994, vols. 212–215, pp. 399–403.

I.V. Gorynin, S.A. Fabritsiev, and V.V. Rybin: J. Nucl. Mater., 1992, vols. 191–194, pp. 401–06.

R.J. Weggel, J.O. Ratka, W.D. Spiegelberg, and Y. Sakai: IEEE Trans. Magn., 1994, vol. 30 (4), pp. 2188–91.

“Elbrodur Cu-Cr-Zr Alloys,” Technical Data Brochure on Cu Alloy Moulds for Continuous Casting, KM Europa-Metal (Kabelmetal), Oshabruck, Germany, Mar. 1997.

R.R. Solomon, A.V. Nadkarni, and J.D. Troxell: University of Illinois at Urbana-Champaign, Urbana, IL, personal communication, Oct. 3, 1995.

J.-P. Blanchet: Rev. Metall.-CIT, 1982, vol. 82, pp. 237–52.

P.F. Kozlowski, B.G. Thomas, J.A. Azzi, and H. Wang: Metall. Trans. A, 1992, vol. 23A, pp. 903–18.

L. Shi and D.O. Northwood: J. Mater. Eng. Performance, 1995, vol. 4 (2), pp. 196–211.

S.J. Zinkle: Report No. DOE/ER-0045/16, Department of Energy, Oak Ridge National Laboratory, Oak Ridge, TN, Mar. 31, 1986, pp. 164–67.

J.E. Synk and K. Vedula: Mater. Sci. Technol., 1987, vol. 3, pp. 72–75.

J.J. Stephen and D.T. Schmale: Report No. SAND87-1296, Sandia National Laboratories, Albuquerque, NM, 1987.

J.J. Stephen, R.J. Bourcier, F.J. Vigil, and D.T. Schmale: Report No. SAND88-1351, Sandia National Laboratories, Albuquerque, NM, 1988.

V.R. Barabash, G.L. Saksugansky, Y.F. Shevakin, et al.: ITER-IL-NE-1-0-3, ITER Joint Central Team, San Diego JWS, La Jolla, CA, USA, Feb. 1990.

T.J. Miller, S.J. Zinkle, and B.A. Chin: J. Nucl. Mater., 1991, vols. 179–181, pp. 263–66.

H. Gravemann: “Materials for Mold Liners for Continuous Casting of Steel Present Position and Latest Trends,” Presented at the Duisburger StranggieBstage, London, 1984.

W. Vandermeulen, V. Massaut, J.V.D. Velde, and W. Hendrix: Proc. 14th Symp. on Fusion Technology, Pergamon Press, New York, NY, 1986, pp. 1031–35.

S.V. Raj and T.G. Langdon: Acta Metall., 1988, vol. 37 (3), pp. 843–52.

M.S. Nagorka, G.E. Lucas, and C.G. Levi: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 873–82.

S.E. Broyles, K.R. Anderson, J.R. Groza, and J.C. Gibeling: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 1217–27.

A. Ayensu and T.G. Langdon: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 901–07.

M.A. Morris and J.C. Joye: Acta Mater., 1995, vol. 43 (1), pp. 69–81.

C. Dubois and M.A. Morris: Scripta Metall. Mater., 1994, vol. 30 (7), pp. 827–32.

W.D. Nix and J.C. Gibeling: Flow and Fracture at Elevated Temperature, ASM, Metals Park, OH, 1985.

P.W. Taubenlat, W.E. Smith, and A.R. Graviano: High Conductivity Copper and Aluminum Alloys, TMS-AIME, Warrendale, PA, 1984, pp. 19–29.

J. Robles, K.R. Anderson, J.R. Groza, and J.C. Gibeling: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 2235–45.

T.S. Srivatsan, S. Anand, and J.D. Troxell: Eng. Fract. Mech., 1993, vol. 46 (2), pp. 183–98.

ABAQUS User’s Manual, K. Hibbitt, and Sorensen, Inc., Providence, RI, 1997.

O.C. Zienkiewicz: The Finite Element Method, 3rd ed., McGraw-Hill Book Company Limited, New York, NY, 1984.

S. Suresh: Fatigue of Materials, Cambridge University Press, Cambridge United Kingdom, 1991, p. 617.

S.S. Manson: Report No. 1170, National Advisory Commission on Aeronautics, Lewis Flight Propulsion Laboratory, Cleveland.

S.S. Manson and G.R. Halford: Int. J. Fract., 1981, vol. 17, pp. 169.

L.F. Coffin: Trans. ASME, 1954, vol. 76, pp. 931–50.

H. Sehitoglu: “Thermal Mechanical Fatigue Life Prediction Methods,” ASTM STP, 1990, vol. 1122, pp. 47–77.

J.F. Stubbins, P. Kurath, D. Drockelman, G.D. Morgan, J. McAfee, G. Li, and B.G. Thomas: 1995 16th IEEE/NPSS Symp. on Fusion Engineering, University of Illinois at Urbana-Champaign, Urbana, IL, 1995, pp. 174–77.

K.D. Leedy and J.F. Stubbins: University of Illinois at Urbana-Champaign, Urbana, IL, private communication, June 1996.

B.E. Jelke: Master’s Thesis, University of Illinois at Urbana-Champaign, Urbana, IL, 1989.

K. Hatanaka and Y. Ishimoto: Proc. 1992 Joint ASME/JSME Conf. on Electronic Packaging, Milpitas, CA, ASME, New York, NY, 1992, pp. 813–18.

M.C. Billone: Report No. DOE/ER-0313/19, Fusion Reactor Material Semiannual Progress Report Argonne National Laboratory, Argonne, IL, Dec. 31, 1995, p. 295.

G. Li: Ph.D. Thesis, University of Illinois at Urbana-Champaign, Urbana, 1996.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Li, G., Thomas, B.G. & Stubbins, J.F. Modeling creep and fatigue of copper alloys. Metall Mater Trans A 31, 2491–2502 (2000). https://doi.org/10.1007/s11661-000-0194-z

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-000-0194-z