Abstract

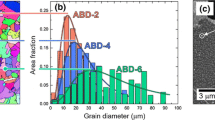

The effects of sulfur, with content variations of 15 to 175 ppm, on the stress-rupture and tensile properties in nickel-base alloy 718 are reported. The stress-rupture life dramatically decreased with increasing sulfur content. This was especially noticeable in the ductility loss at 650 °C. Auger electron spectroscopy of stress-rupture tested specimens provided direct evidence of sulfur and phosphorus segregation to grain boundaries and carbide/matrix interfaces. The stress-rupture life and fracture morphology were both found to correlate with the segregation of sulfur at grain boundaries in alloy 718. Sulfur was also preferentially segregated at the carbide matrix surfaces, and phosphorus was found to be distributed on grain boundaries. However, the phosphorus segregation did not correlate with stress-rupture behavior. Sulfur contents in the range of 15 to 50 ppm had little effect on the stress-rupture life. However, the stress-rupture life decreased dramatically with increasing sulfur content above 50 ppm.

Similar content being viewed by others

References

I.C. Howard and A.A. Willoughby: Developments in Fracture Mechanics—2, Applied Science, 1981, p. 39.

A.R. Rosenfield: Metall. Rev., 1968, vol. 13, p. 29.

J.R. Rice and M.A. Johnson: Inelastic Behaviour of solids, McGraw-Hill, New York, NY, 1970, p. 41.

P. Sevc, J. Janovec, and V. Katana: Scripta Metall., 1994, vol. 31, pp. 1673–78.

G.G. Garrett and J.F. Knott: Metall. Trans. A, 1978, vol. 9A, pp. 1187–1201.

R.G. Thompson, B. Radhakrishnan, and D.E. Mayo: J. Phys., 1988, vol. 49, pp. C5-471.

D.P. Pope and D.S. Wilkinson: in Creep and Fracture of Engineering Materials and Structures, B. Wilshire and D.R.J. Owen, eds., Pineridge Press, Swansea, United Kingdom, 1981.

D. Gupta: Metall. Trans. A, 1977, vol. 8A, pp. 1431–38.

C.J. Middleton: Phil. Trans. R. Soc. London A, 1980, vol. 295, p. 305.

L.M.T. Hopkin and E.A. Jenkinson: J. Iron Steel Inst., 1962, vol. 200, p. 356.

R. Bruscato: Welding Res. Suppl., 1970, vol. 35, p. 148s.

K.A. Abiko, R.L. Bodnar, and D.P. Pope: in Ductility and Toughness Considerations in Elevated Temperature Service, G.V. Smith, ed., ASME, New York, NY, 1978, pp. 1–10.

D.S. Wilkinson, K. Abiko, N. Thyagarajan, and D.P. Pope: Metall. Trans. A, 1980, vol. 11, pp. 1827–36.

M. Polak: Surface Segregation Phenomena, P.A. Dowben and A. Miller, eds., CRS, Boston, MA, 1990, pp. 292–301.

C.L. White, J.H. Schneibel, and R.A. Padgett: Metall. Trans. A, 1983, vol. 14A, pp. 595–610.

J. Kameda and C.J. Mcmahon, Jr.: Metall. Trans. A, 1981, vol. 12A, pp. 31–37.

A. Mitchell: in Superalloys 718, 625, 706 and Various Derivatives, E.A. Loria, ed., TMS, Warrendale, PA, 1994, p. 109.

R. T. Holt and W. Wallace: Int. Met. Rev., 1976.

J.M. Walsh and N.P. Anderson: Superalloys, TMS-AIME, Warrendale, PA, 1976, pp. 127–36.

I. Kirman and D.H. Warrington: Metall. Trans., 1970, vol. 1, pp. 2667–75.

J.M. Oblak, D.F. Paulonis, and D.S. Puvall: Metall. Trans., 1974, vol. 5, pp. 143–53.

J.F. Radavich: J. Met., 1988, vol. 7, p. 42.

J. Larson: Metall. Trans. A, 1976, vol. 7A, pp. 1497–1502.

C. Sims, N. Stoloff, and W. Hagel: Superalloys II, John Wiley & Sons, New York, NY, 1987.

C. Hammond and J. Nutting: Met. Sci., 1977, p. 474.

J.X. Dong: Ph.D. Thesis, University of Science and Technology Beijing, Beijing, 1994.

P. Kotval, J. Venables, and R. Calders: Metall. Trans. A, 1972, vol. 3A, pp. 453–58.

H.G. Gray: NASA TN D-7805, NASA, Washington, DC, Jan. 1975.

E.D. Lawrence, N.C. MacDonald, and P.W. Palmberg: Handbook of Auger Electron Spectroscopy, Physical Electronics Industries, Inc., 1980.

R.G. Thompson, M.C. Koopman, and B.H. King: in Superalloys 718, 625 and Various Derivatives, E.A. Loria, ed., TMS, Warrendale, PA, 1991, p. 53.

P.J. Valdez and J.B. Steinman: Effects of Minor Elements on the Weldability of High-Nickel Alloys, Welding Research Council, New York, NY, p. 93.

W. Yeniscauich and C.W. Fox: Effects of Minor Elements on the Weldability of High-Nickel Alloys, Welding Research Council, New York, NY, p. 24.

R.A. Mulford: Metall. Trans. A, 1983, vol. 14A, pp. 865–70.

C.L. Briant and R.A. Mulford: Metall. Trans. A, 1982, vol. 13A, pp. 745–52.

G.S. Was, H.H. Tischner, and R.M. Latanision: Metall. Trans. A, 1981, vol. 12A, pp. 1397–1408.

W.C. Johnson, J.E. Doherty, B.H. Kear, and A.F. Giamei: Scripta Metall., 1974, vol. 8, pp. 971–74.

A.W. Thompson: Scripta Metall., 1974, vol. 8, p. 607.

C.L. White, R.A. Padgett, and R.W. Swindeman: Scripta Metall., 1981, vol. 15, pp. 777–82.

C.L. White, J.H. Schneibel, and R.A. Padgett: Metall. Trans. A, 1983, vol. 14A, pp. 595–610.

R. Raj and M.F. Ashby: Acta Metall., 1975, vol. 23, pp. 653–66.

H. Trinkaus and H. Ullmaier: Phil. Mag. A, 1979, vol. 39, p. 563.

A.G. Evans, J.R. Rice, and J.P. Hirth: J. Am. Ceram. Soc., 1980, vol. 63, p. 368.

C.L. White: in Aluminum Lithium Alloys, TH. Sanders, Jr. and E.A. Starke, Jr., eds., TMS-AIME, Warrendale, PA, 1981, p. 141.

J.W. Gibbs: The Scientific Papers of J. Willand Gibbs, Dover NY, 1961, vol. 10, pp. 219–331.

E.A. Guggenheim: Thermodynamics, North-Holland, Amsterdam, 1967, pp. 1–60.

C.L. White and D.F. Stein: Metall. Trans. A, 1978, vol. 9A, pp. 13–22.

C.L. White and W.A. Coghlan: Metall. Trans A, 1977, vol. 8A, pp. 1403–12.

M.H. Yoo and H. Trinkaus: Metall. Trans. A, 1983, vol. 14A, pp. 547–61.

M.C. Inaman, D. McLean, and H.R. Tipler: Proc. R. Soc. A, 1963, vol. A273, p. 538.

W.D. Cao and R.L. Kennedy: Superalloys 718, 625 706 and Various Derivatives, E.A. Loria, ed., TMS, Warrendale, PA, 1994, p. 463.

X.S. Xie, X. Liu, Y. Hu, and J.X. Dong: in Superalloys 1996, R.D. Kissinger, ed., TMS, Warrendale, PA, 1996, p. 599.

W.D. Cao, and R.L. Kennedy: in Superalloys 1996, R.D. Kissinger, ed., TMS, Warrendale, PA, 1996, p. 589.

M. Gao, D.J. Dwyer, and R.P. Wei: Scripta Metall., 1995, vol. 32, pp. 1169–74.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Dong, J.X., Xie, X.S. & Thompson, R.G. The influence of sulfur on stress-rupture fracture in inconel 718 superalloys. Metall Mater Trans A 31, 2135–2144 (2000). https://doi.org/10.1007/s11661-000-0131-1

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-000-0131-1