Abstract

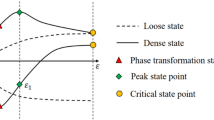

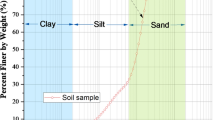

During recent seismic events, such as 2010 Darfield and 2016 Ecuador earthquakes, widespread liquefaction has been observed in sand deposits with silt content. Nevertheless, the presence of non-plastic fines implies variable liquefaction resistance of sands. The goal of this research is the assessment of the influence of non-plastic fines and mixture-packing conditions on liquefaction triggering. A series of monotonic and cyclic consolidated undrained triaxial as well as resonant column tests is carried out on reconstituted soil specimens. The behavior of loose, medium and dense silty sands is analyzed, using different fine contents and confining pressures. The results show that the behavior of mixtures strongly depends on the packing configuration of coarse and fine particles. The experimental results are analyzed in terms of equivalent intergranular void ratio, which is identified in the literature as an adequate state parameter to characterize the global effect of fine particles. The estimation of the equivalent intergranular void ratio requires the determination of the active fine fraction b participating in the force transfer. An original formula is proposed for the parameter b based on packing configuration. The validation of the proposed formula is undertaken through comparisons with the present experimental results but also with results reported in the literature. The proposed expression to estimate the active fine fraction b allows a satisfactory prediction of liquefaction triggering in sand-fines mixtures independently from the fine content.

Similar content being viewed by others

References

AFNOR NFP94-059 (2000) Sols: reconnaissance et essais: déterminationdes masses volumiques minimale et maximale des sols non cohérents.

Amini F, Qi GZ (2000) Liquefaction testing of stratified silty sands. J Geotech Geoenvironmental Eng 126:208–217

Askari F, Dabiri R, Shafiee A, Jafari MK (2010) Effects of non-plastic fines content on cyclic resistance and post liquefaction of sand-silt mixtures based on shear wave velocity

Belkhatir M, Arab A, Della N et al (2010) Liquefaction resistance of Chlef river silty sand: effect of low plastic fines and other Parameters. Acta Polytech Hungarica 7:119–137

Carraro JAH, Bandini P, Salgado R (2005) Liquefaction resistance of clean and silty sands from cone penetration resistance. Geotech Spec Publ 129:1337–1351. https://doi.org/10.1061/40779(158)31

Castro G (1969) Liquefaction of sands. Harvard University, Cambridge

Chang CS, Deng Y, Goudarzy M, Rahman MM, Wichtmann T (2021) Discussion: revisiting the concept of inter-granular void ratio in view of particle packing theory. Geotech Lett. https://doi.org/10.1680/jgele.18.00175

Cubrinovski M, Green RA, Allen J et al (2010) Geotechnical reconnaissance of the 2010 Darfield (Canterbury) earthquake. Bull New Zeal Soc Earthq Eng 43:243–320. https://doi.org/10.5459/bnzsee.43.4.243-320

Cubrinovski M, Ishihara K (2002) Maximum and minimum void ratio characteristics of sands. Soils Found 42:65–78

Dezfulian H (1986) Liquefaction potential of silty sand site. Int J Rock Mech Min Sci Geomech Abstr 23:90. https://doi.org/10.1016/0148-9062(86)91083-1

Hardin BO, Drnevich VP (1972) Shear modulus and damping in soils: design equations and curves. J Soil Mech Found Div 98:667–692

Ishihara K (1993) Liquefaction and flow failure during earthquakes. Geotechnique 43:351–451

Iwasaki T, Tatsuoka F (1977) Effects of grain size and grading on dynamic shear moduli of sands. Soils Found 17:19–35

Jamiolkowski M, Lancellotta R, Lo Presti DCF (1995) Remarks on the stiffness at small strains of six Italian clays. Pre-failure deformation of geomaterials, pp 817–836

JGS-0161 (2009) Test method for minimum and maximum densities of sands, Standards of the Japanese Geotechnical Society

Kishida H (1969) Characteristics of liquefied sands during Mino-Owari, Tohnankai, and Fukui earthquakes. Soils Found 9:75–92

Koester JP (1994) Influence of fines type and content on cyclic strength. In: Ground failures under seismic conditions. ASCE, pp 17–33

Kuerbis R, Negussey D, Vaid YP (1988) Effect of gradation and̄ fines content on the undrained response of sand. In: Proceedings of the Hydraulic fill structure, Geotechnic. ASCE, pp 330–345

Ladd RS (1978) Preparing test specimens using undercompaction. Geotech Test J 1:16–23

Lade PV, Liggio CD, Yamamuro JA (1998) Effects of non-plastic fines on minimum and maximum void ratios of sand. Geotech Test J 21:336–347

Lade PV, Yamamuro JA (1997) Effects of nonplastic fines on static liquefaction of sands. Can Geotech J 34:918–928. https://doi.org/10.1139/t97-052

Li XS, Wang Y (1998) Linear representation of steady-state line for sand. J Geotech geoenvironmental Eng 124:1215–1217

Liu X, Yang J (2018) Shear wave velocity in sand: effect of grain shape. Geotechnique 68:742–748. https://doi.org/10.1680/jgeot.17.T.011

Mitchell JK (1976) Fundamentals of soil behavior, vol 3. Wiley, New York

Mohammadi A, Qadimi A (2015) A simple critical state approach to predicting the cyclic and monotonic response of sands with different fines contents using the equivalent intergranular void ratio. Acta Geotech 10:587–606. https://doi.org/10.1007/s11440-014-0318-z

Murthy TG, Loukidis D, Carraro JAH et al (2008) Undrained monotonic response of clean and silty sands. Geotechnique 58:536–538. https://doi.org/10.1680/geot.2008.D.002

Naeini SA, Baziar MH (2004) Effect of fines content on steady-state strength of mixed and layered samples of a sand. Soil Dyn Earthq Eng 24:181–187. https://doi.org/10.1016/j.soildyn.2003.11.003

Nguyen TK, Benahmed N, Hicher PY (2017) Determination of the equivalent intergranular void ratio: application to the instability and the critical state of silty sand. EPJ Web Conf 140:2017–2020. https://doi.org/10.1051/epjconf/201714002019

Ni Q, Tan TS, Dasari GR, Hight DW (2004) Contribution of fines to the compressive strength of mixed soils. Géotechnique 54:561–569. https://doi.org/10.1680/geot.54.9.561.56936

Okashi Y (1970) Effects Of Sand Compaction On Liquefaction During Tokachioki Earthquake. Soils Found 10:112–128

Oztoprak S, Bolton MD (2013) Stiffness of sands through a laboratory test database. Geotechnique 63:54–70. https://doi.org/10.1680/geot.10.P.078

Papadopoulou A, Tika T (2008) The effect of fines on critical state and liquefaction resistance characteristics of non-plastic silty sands. Soils Found 48:713–725. https://doi.org/10.3208/sandf.48.713

Pitman TD, Robertson PK, Sego DC (1994) Influence of fines on the collapse of loose sands. Can Geotech J 31:728–739. https://doi.org/10.1139/t94-084

Porcino DD, Diano V (2017) The influence of non-plastic fines on pore water pressure generation and undrained shear strength of sand-silt mixtures. Soil Dyn Earthq Eng 101:311–321. https://doi.org/10.1016/j.soildyn.2017.07.015

Rahman MM, Lo SR, Baki MAL (2011) Equivalent granular state parameter and undrained behaviour of sand-fines mixtures. Acta Geotech 6:183–194. https://doi.org/10.1007/s11440-011-0145-4

Rahman MM, Lo SR, Gnanendran CT (2008) On equivalent granular void ratio and steady state behaviour of loose sand with fines. Can Geotech J 45:1439–1456. https://doi.org/10.1139/T08-064

Rollins KM, Evans MD, Diehl NB, III WDD (1998) Shear modulus and damping relationships for gravels. J Geotech Geoenviron Eng 124:396–405

Sarkar D, Goudarzy M, Ko D, Wichtmann T (2020) Influence of particle shape and size on the threshold fines content and the limit index void ratios of sands containing non-plastic fines. Soils Found 60:621–633. https://doi.org/10.1016/j.sandf.2020.02.006

Seed HB, Tokimatsu K, Harder LF, Chung RM (1985) The influence of SPT procedures in soil liquefaction resistance evaluations. J Geotech Eng 111:1425–1445

Stamatopoulos CA (2010) An experimental study of the liquefaction strength of silty sands in terms of the state parameter. Soil Dyn Earthq Eng 30:662–678. https://doi.org/10.1016/j.soildyn.2010.02.008

Thevanayagam S (1998) Effect of fines and confining stress on undrained shear strength of silty sands. J Geotech Geoenvironmental Eng. https://doi.org/10.1061/(ASCE)1090-0241(1999)125:11(1024)

Thevanayagam S, Fiorillo M, Liang J (2000) Effect of non-plastic fines on undrained cyclic strength of silty sands. Soil Dyn Liq 2000:77–91

Thevanayagam S, Martin GR (2002) Liquefaction in silty soils: screening and remediation issues. Soil Dyn Earthq Eng 22:1035–1042. https://doi.org/10.1016/S0267-7261(02)00128-8

Tohno I, Yasuda S (1981) Liquefaction of the ground during the 1978 Miyagiken-Oki earthquake. Soils Found 21:18–34

Tokimatsu K, Yoshimi Y (1983) Empirical correlation of soil liquefaction based on SPT N-value and fines content. Jpn Soc Soil Mech Found Eng 23:56–74

Xenaki VC, Athanasopoulos GA (2003) Liquefaction resistance of sand-silt mixtures: an experimental investigation of the effect of fines. Soil Dyn Earthq Eng 23:1–12. https://doi.org/10.1016/S0267-7261(02)00210-5

Yang SL, Sandven R, Grande L (2006) Steady-state lines of sand-silt mixtures. Can Geotech J 43:1213–1219. https://doi.org/10.1139/T06-069

Yang J, Wei LM (2012) Collapse of loose sand with the addition of fines: The role of particle shape. Geotechnique 62:1111–1125. https://doi.org/10.1680/geot.11.P.062

Zhu Z, Zhang F, Dupla J et al (2021) Assessment of tamping-based specimen preparation methods on static liquefaction of loose silty sand. Soil Dyn Earthq Eng 143:106592. https://doi.org/10.1016/j.soildyn.2021.106592

Zlatović S, Ishihara K (1995) On the influence of nonplastic fines on residual strength. First Int Conf Earthq Geotech Eng 95:239–244

Acknowledgements

This research is carried out in the framework of the French National Project “Characterizing and Improving SOiLs AgainsT liquEfaction” (ISOLATE, Projet-ANR-17-CE22-0009) funded by the French National Research Agency.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

See Figs.

Steady-state lines for the natural Camargue silty sand (Nguyen et al. [28]), using (a) the global void ratio and (b) the proposed equivalent intergranular void ratio

20,

Steady-state lines for M31 clean quartz sand and non-plastic silt from Assyros in Greece (Papadopoulou and Tika [32]), using (a) the global void ratio and (b) the proposed equivalent intergranular void ratio

21,

Steady-state lines for natural sand from the Egyptian desert and non-plastic silt from the area of Assirou in Greece (Stamatopoulos [40]), using (a) the global void ratio and (b) the proposed equivalent intergranular void ratio

22,

Cyclic stress ratio CSR15 for the Ottawa sand and Sil-Co-Sil silica by US Silica Co. (Carraro et al. [5]) with respect to (a) the global void ratio and (b) the proposed equivalent intergranular void ratio

23 and

Cyclic stress ratio CSR15 for natural soil from Shinias-Marathon in Greece (Xenaki and Athanasopoulos [46]) with respect to (a) the global void ratio and (b) the proposed equivalent intergranular void ratio

24.

Rights and permissions

About this article

Cite this article

Gobbi, S., Reiffsteck, P., Lenti, L. et al. Liquefaction triggering in silty sands: effects of non-plastic fines and mixture-packing conditions. Acta Geotech. 17, 391–410 (2022). https://doi.org/10.1007/s11440-021-01262-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-021-01262-1