Abstract

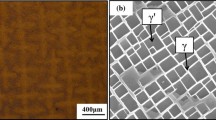

In order to clarify the differences of very high cycle fatigue (VHCF) behavior of nickel based superalloy IN718 with different loading frequencies, stress-controlled fatigue tests were carried out by using ultrasonic testing method (20 KHz) and rotary bending testing method (52.5 Hz), both at room temperatures, to establish stress versus cycles to failure (S-N) relationships. Results disclosed that cycles to failure at a given stress level increased with an increase of the applied frequency, i.e., the higher frequency produced an upper shift of the S-N curves. Fractographic analysis suggested that crack initiation and propagation behaviors had large differences: cracks in low-frequency tests preferentially initiated from multiple sources on the specimen surface, while in high-frequency tests, cracks mostly originated from a unique source of subsurface inclusions. Subsequently, frequency-involved modeling was proposed, based on the damage accumulation theory, which could well illustrate qualitatively those comparisons due to different loading frequencies.

Similar content being viewed by others

References

Furuya Y. Size effect in gigacycle fatigue of high-strength steel under ultrasonic fatigue testing. Procedia Eng, 2010, 2: 485–490

Hoffelner W, Kromp K, Weiss B. Effect of test frequency on fatigue hardening behavior of aluminum. Scripta Metall Mater, 1975, 9: 1157–1161

Karlashov A V, Tokarev V P, Sazonov V V. Frequency effect during fatigue of alloy D16T in conditions of high temperature and local stress concentrations. In: Fiziko-Khimicheskaya Mekhanika Materialov, Fiziko-Khimicheskaya Mekhanika Materialov, Soviet Materials Science, 1975. 11

Bathias C, Paris P C. Gigacycle fatigue in mechanical practice. New York: Marcel Dekker, 2005

Wang Q Y, Berard J Y, Dubarre A. Gigacycle fatigue of ferrous alloys. Fatigue Fract Eng Mater Struct, 1999, 22: 667–672

Furuya Y, Matsuoka S, Abe T, et al. Gigacycle fatigue properties for high strength low-alloy steel at 100Hz, 600Hz and 20KHz. Scr Mater, 2002, 46: 157–162

Bayraktar E, Garcias I M, Bathias C. Failure mechanisms of automotive metallic alloys in very high cycle fatigue range. Int J Fatigue, 2006, 28: 1590–1602

Huang J, Spowart J E, Jones J W. Fatigue behaviour of SiCp-reinforced aluminium composites in the very high cycle regime using ultrasonic fatigue. Fatigue Fract Eng Mater Struct, 2006, 29: 507–517

Bathias C. Piezoelectric fatigue testing machines and devices. Int J Fatigue, 2006, 28: 1438–1445

Wang Q Y, Berard J Y, Dubarre A, et al. Fatigue characterization of a spheroidal graphite cast iron under ultrasonic loading. J Mater Sci, 2004, 39: 687–689

Furuya Y, Matsuoka S. Improvement of gigacycle fatigue properties by modified ausforming in 1600 and 2000 MPA-class low-alloy steels. Metall Mater Trans A, 2002, 33: 3421–3431

Yi J Z, Torbet C J, Feng Q, et al. Ultrasonic fatigue of a single crystal Ni-base superalloy at 1000 C. Mater Sci Eng A, 2007, 443: 142–149

Korth G, Smolik G. Status Report of Physical and Mechanical Test of Alloy 718. Report tree-1254, EG&G Idaho, Inc, 1978

Kawagoishi N, Chen Q, Nisitani H. Fatigue strength of Inconel 718 at elevated temperatures. Fatigue Fract Eng Mater Struct, 2000, 23: 209–216

Ma X F, Duan Z, Shi H J. Fatigue and fracture behavior of nickel-based superalloy Inconel 718 up to the very high cycle regime. J Zhejiang Univ-Sci A, 2010, 11: 727–737

Duan Z, Shi H J, Ma X F. Load frequency effect on gigacycle fatigue properties of superalloy Inconel 718. In: 2nd International Conference on Computer Engineering and Technology, 2010, 5: 130–133

Andersson H, Persson C. In-situ SEM study of fatigue crack growth behavior in IN718. Int J Fatigue, 2004, 26: 211–219

Duan Z. Research on gigacycle fatigue properties of high-strength alloys. Dissertation for Doctoral Degree. Beijing: Tsinghua University. 2011

Orowan E. Problems of plastic gliding. Proc Phys Soc, 1940, 52: 8–22

Johnston W G, Gilman J J. Dislocation velocities, dislocation densities, and plastic flow in lithium fluoride crystals. J Appl Phys, 1959, 30: 129–144

Reimers W, Pyzalla A R, Schrever A K, et al. Neutrons and Synchrotron Radiation in Engineering Materials Science: From Fundamentals to Material and Component Characterization. Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA, 2008

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Duan, Z. & Shi, H. Comparison of the very high cycle fatigue behaviors of INCONEL 718 with different loading frequencies. Sci. China Phys. Mech. Astron. 56, 617–623 (2013). https://doi.org/10.1007/s11433-013-5013-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11433-013-5013-9