Abstract

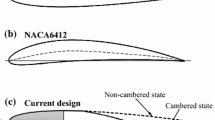

Aerospace vehicles have recently received great attention for their completely reusable in aviation and aerospace. To achieve the optimal aerodynamic performance of the aerospace vehicle, the nose cone needs to change its aerodynamic shape under different flight conditions. However, the structural design of a morphing nose cone that is capable of changing aerodynamic shape adaptively and withstanding prescribed aerodynamic loads remains an ongoing challenge. To overcome this issue and to further advance our previous work, the motion performance of a morphing nose cone inspired by the deformation mechanism of the honeybee abdomen was tested to evaluate the deformation ability and bearing capacity. The dynamic prediction analysis of the morphing nose cone with a clearance joint and flexible links was then investigated to elucidate the crucial issues in the deformation movement. To improve the motion performance, a performance improvement scheme based on redundant constraints drawn from the muscle distribution of the honeybee abdomen was proposed. Finally, the structural stiffness, dynamic analysis, and experimental testing of the improved morphing nose cone were conducted. The experimental results indicate that the extension and contraction ratios and bending angles of the improved morphing nose cone under loads of 0, 10, and 25 kg loads improve by 1.51% and 2.329°, 2.78% and −1.902°, and 5.06% and 1.111°, respectively, verifying the rationality and effectiveness of the performance improvement scheme. This work provides a new reference for the design of the morphing structure for aerospace vehicles.

Similar content being viewed by others

References

Tormo V G, Serghides V C. Initial sizing and reentry trajectory design methodologies for dual-mode-propulsion reusable aerospace vehicles. J Spacecr Rockets, 2007, 44: 1038–1050

Bowcutt K. A perspective on the future of aerospace vehicle design. In: 12th AIAA International Space Planes and Hypersonic Systems and Technologies. Virginia, 2003. 1–10

Zhang Y, Zhao J, Chen W, et al. Biomimetic skeleton structure of morphing nose cone for aerospace vehicle inspired by variable geometry mechanism of honeybee abdomen. Aerosp Sci Tech, 2019, 92: 405–416

Zhao J, Yan S, Deng L, et al. Design and analysis of biomimetic nose cone for morphing of aerospace vehicle. J Bionic Eng, 2017, 14: 317–326

Barbarino S, Bilgen O, Ajaj R M, et al. A review of morphing aircraft. J Intell Material Syst Struct, 2011, 22: 823–877

Ajaj R M, Beaverstock C S, Friswell M I. Morphing aircraft: The need for a new design philosophy. Aerosp Sci Tech, 2016, 49: 154–166

Ameduri S, Concilio A. Morphing wings review: Aims, challenges, and current open issues of a technology. P I Mech Eng C-J Mec, 2020, doi: https://doi.org/10.1177/0954406220944423

Sofla A Y N, Meguid S A, Tan K T, et al. Shape morphing of aircraft wing: Status and challenges. Mater Des, 2010, 31: 1284–1292

Meguid S A, Su Y, Wang Y. Complete morphing wing design using flexible-rib system. Int J Mech Mater Des, 2017, 13: 159–171

Gerdroodbary M B. Aerodynamic Heating in Supersonic and Hypersonic Flows: Advanced Techniques for Drag and Aero-Heating Reduction. Amsterdam: Elsevier Ltd., 2022

Gauer M, Paull A. Numerical investigation of a spiked blunt nose cone at hypersonic speeds. J Spacecr Rockets, 2008, 45: 459–471

Narayan A, Narayanan S, Kumar R, et al. Control of aerodynamic drag and heating of nose cones through taper spikes. J Spacecr Rockets, 2019, 56: 1165–1176

Gerdroodbary M B, Imani M, Ganji D D. Heat reduction using conterflowing jet for a nose cone with aerodisk in hypersonic flow. Aerosp Sci Tech, 2014, 39: 652–665

Pish F, Manh T D, Gerdroodbary M B, et al. Computational study of the cavity flow over sharp nose cone in supersonic flow. Int J Mod Phys C, 2020, 31: 2050079

Huang W. A survey of drag and heat reduction in supersonic flows by a counterflowing jet and its combinations. J Zhejiang Univ Sci A, 2015, 16: 551–561

Jiang Y, Gerdroodbary M B, Sheikholeslami M, et al. Influence of upstream strut on hydrogen fuel distribution inside the supersonic combustion chamber. Int J Hydrogen Energy, 2020, 45: 22032–22040

Li J, Wu J, Yan S. Conceptual design of deployment structure of morphing nose cone. Adv Mech Eng, 2013, 5: 590957

Shi R, Wan W. Analysis of flight dynamics for large-scale morphing aircraft. Aircraft Eng Aerosp Tech, 2015, 87: 38–44

Ericsson L E, Guenther R A. Effect on slender vehicle dynamics of change from spherical to conical nose bluntness. J Spacecr Rockets, 1972, 9: 435–440

Schmidt L V. Introduction to aircraft flight dynamics. Reston: AIAA, 1998. 165–186

Xu B, Shi Z K. An overview on flight dynamics and control approaches for hypersonic vehicles. Sci China Inf Sci, 2015, 58: 1–19

Kim B. A methodology of an equivalent beam modeling for a nose-cone of a missile. In: 28th Structures, Structural Dynamics and Materials Conference. Colorado, 1987. 1085–1092

Deepak N R, Ray T, Boyce R R. Evolutionary algorithm shape optimization of a hypersonic flight experiment nose cone. J Spacecr Rockets, 2008, 45: 428–437

Anderson M B, Burkhalter J E, Jenkins R M. Missile aerodynamic shape optimization using genetic algorithms. J Spacecr Rockets, 2000, 37: 663–669

Li D, Zhao S, Da Ronch A, et al. A review of modelling and analysis of morphing wings. Prog Aerosp Sci, 2018, 100: 46–62

Sun R J, Chen G P, Zhou C, et al. Multidisciplinary design optimization of adaptive wing leading edge. Sci China Tech Sci, 2013, 56: 1790–1797

Obradovic B, Subbarao K. Modeling of dynamic loading of morphing-wing aircraft. J Aircraft, 2011, 48: 424–435

Guo X, Wang S, Qu Y, et al. Nonlinear dynamics of Z-shaped morphing wings in subsonic flow. Aerosp Sci Tech, 2021, 119: 107145

Gamboa P, Vale J, Lau F J P, et al. Optimization of a morphing wing based on coupled aerodynamic and structural constraints. AIAA J, 2009, 47: 2087–2104

Concilio A, Dimino I, Pecora R, et al. Aircraft morphing systems: Elasticity of selected components and modelling issues. In: Active and Passive Smart Structures and Integrated Systems XIV. California, 2020. 147–158

Kan Z, Li D, Shen T, et al. Aerodynamic characteristics of morphing wing with flexible leading-edge. Chin J Aeronaut, 2020, 33: 26102619

Sleesongsom S, Bureerat S. Effect of actuating forces on aeroelastic characteristics of a morphing aircraft wing. In: Applied Mechanics and Materials. Zurich, 2011. 308–317

Ajaj R M, Parancheerivilakkathil M S, Amoozgar M, et al. Recent developments in the aeroelasticity of morphing aircraft. Prog Aerosp Sci, 2021, 120: 100682

Xie C C, Liu Y, Yang C. Theoretic analysis and experiment on aeroelasticity of very flexible wing. Sci China Tech Sci, 2012, 55: 2489–2500

Zhang J, Shaw A D, Wang C, et al. Aeroelastic model and analysis of an active camber morphing wing. Aerosp Sci Tech, 2021, 111: 106534

Cook J R, Smith M J. Stability of aeroelastic airfoils with camber flexibility. J Aircraft, 2014, 51: 2024–2027

Ajaj R M, Friswell M I. Aeroelasticity of compliant span morphing wings. Smart Mater Struct, 2018, 27: 105052

Andersen G, Cowan D, Piatak D. Aeroelastic modeling, analysis and testing of a morphing wing structure. In: 48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference. Hawall, 2007. 1–15

Samuel J B, Pines D. Design and testing of a pneumatic telescopic wing for unmanned aerial vehicles. J Aircraft, 2007, 44: 1088–1099

Communier D, Botez R M, Wong T. Experimental validation of a new morphing trailing edge system using Price-Païdoussis wind tunnel tests. Chin J Aeronaut, 2019, 32: 1353–1366

Feng S Y, Guo Q F, Wang J J, et al. Influence of membrane wing active deformation on the aerodynamic performance of an aircraft model. Sci China Tech Sci, 2022, 65: 2474–2484

Ledu J, Pollak C. Flight testing results on a hypersonic re-entry nose cone. J Spacecr Rockets, 1969, 6: 1044–1047

Wang J, Zhao L, Wang X, et al. An experimental investigation on transpiration cooling of wedge shaped nose cone with liquid coolant. Int J Heat Mass Transfer, 2014, 75: 442–449

Wu N, Wang J, He F, et al. An experimental investigation on transpiration cooling of a nose cone model with a gradient porosity layout. Exp Thermal Fluid Sci, 2019, 106: 194–201

Luu T, Cheung A, Ball D, et al. Honeybee flight: A novel ‘streamlining’ response. J Exp Biol, 2011, 214: 2215–2225

Zhao J, Yan S, Wu J. Critical structure for telescopic movement of honey bee (Insecta: Apidae) abdomen: Folded intersegmental membrane. J Insect Sci, 2016, 16: 79

Zhang Y, Yan S, Liang Y. A novel bioinspired mechanism to elucidate the movement flexibility of the honeybee abdomen driven by muscles. Insect Sci, 2022, 29: 1181–1194

Johnson K L. Energy dissipation at spherical surfaces in contact transmitting oscillating forces. J Mech Eng Sci, 1961, 3: 362–368

Machado M, Moreira P, Flores P, et al. Compliant contact force models in multibody dynamics: Evolution of the Hertz contact theory. Mechanism Machine Theor, 2012, 53: 99–121

Zhang Y, Gu Y, Liu T, et al. Dynamic behavior and parameter sensitivity of the free-floating base for space manipulator system considering joint flexibility and clearance. P I Mech Eng C-J Mec, 2019, 233: 895–910

Lankarani H M, Nikravesh P E. A contact force model with hysteresis damping for impact analysis of multibody systems. In: International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Canada, 1989. 45–51

Xiang W W K, Yan S Z, Wu J N. A comprehensive method for joint wear prediction in planar mechanical systems with clearances considering complex contact conditions. Sci China Tech Sci, 2015, 58: 86–96

Zhang Y, Pang X, Yang Y, et al. Effect of calcium ion on the morphology structure and compression elasticity of muscle fibers from honeybee abdomen. J Biomech, 2021, 127: 110652

Hao G, Kong X. A novel large-range XY compliant parallel manipulator with enhanced out-of-plane stiffness. J Mech Des, 2012, 134: 061009

Zhao Q, Guo J, Hong J. Assembly precision prediction for planar closed-loop mechanism in view of joint clearance and redundant constraint. J Mech Sci Technol, 2018, 32: 3395–3405

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the China Postdoctoral Science Foundation (Grant No. 2022M721822), the National Natural Science Foundation of China (Grant No. 51475258), and the free exploration project of State Key Laboratory of Tribology, Tsinghua University (Grant No. SKLT2020B04).

Rights and permissions

About this article

Cite this article

Zhang, Y., Li, C., Zhang, Y. et al. Experimental investigations on structural improvement of morphing mechanism for nose cone of aerospace vehicle adopting a bionic redundant constraint strategy. Sci. China Technol. Sci. 66, 1075–1095 (2023). https://doi.org/10.1007/s11431-022-2320-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-022-2320-6