Abstract

Background, aim, and scope

North American pulp and paper mills are facing tremendous challenges, which may necessitate major mill modernizations. An example is process modification to reduce dependency on purchased power, which is an expensive resource. Such modifications may have environmental implications at the mills’ sites, on their product life cycle, and on other interconnected systems, and therefore, systematic tools such as life cycle assessment (LCA) need to be applied. Different LCA system boundary approaches can be used for such process design applications, and these approaches need to be compared to determine their respective benefits and limitations in this context. This study compares setting the system boundary according to a cradle-to-gate approach [attributional LCA (ALCA)] and a system expansion [consequential LCA (CLCA)] approach using a case study, which deals with implementing cogeneration and increased de-inked pulp production at an integrated newsprint mill.

Methodology

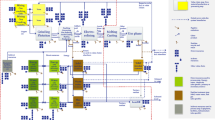

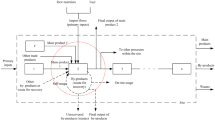

A case study considering various process options to reduce purchased electricity at an integrated newsprint mill is defined. These options include implementing cogeneration and increasing de-inked pulp production. The environmental impacts related to these process options are analyzed using two LCA methodologies. The first one consists in setting the system boundary according to a cradle-to-gate ALCA approach, while the second one uses a differential CLCA approach (system expansion). Comparisons of the two methods are based on different parameters: inclusion/exclusion of the indirect environmental consequences, selected allocation procedures, and effect of using the average versus the marginal technology for power production.

Results

Both the ALCA approach and the CLCA approach indicate that the process options are beneficial. However, the results show that indirect environmental consequences, which are assessed only with the CLCA approach, can be opposite to direct effects (e.g., the results can indicate an improvement of the direct impacts and a deterioration of the indirect ones). In addition, environmental impacts obtained by modeling the average or the marginal technology may be very different. Using an ALCA approach often necessitates the use of an arbitrary allocation procedure, which can greatly affect the results. On the other hand, ALCA can be used to perform “hot spots” identification, which, at this time, is not possible with CLCA.

Discussion

The cradle-to-gate boundary approach, which is usually used in the literature for pulp and paper process design applications, may not always be the most appropriate to determine the environmental consequences of implementing different process options. However, at this time, there is no method based on CLCA allowing for “hot spots” identification, and thus, a combined approach may be required for process design.

Conclusions

It is shown that the choice of the system boundary can significantly affect the results. More specifically, the usage of different allocation procedures in ALCA leads to different interpretation of the results, which does not occur when using the CLCA approach. CLCA provides more complete information for decision making for the cases where most of the consequences occur outside the life cycle of the product investigated.

Recommendations and perspectives

Research opportunities include developing methodologies to integrate ALCA and CLCA for improved process design applications and mechanisms for reducing uncertainty in CLCA.

Similar content being viewed by others

References

Bare JC, Norris GA, Pennington DW, McKone T (2003) Traci: the tool for the reduction and assessment of chemical and other environmental impacts. J Ind Ecol 3–4(6):49–78

Cornejo F, Janssen M, Gaudreault C, Samson R, Stuart PR (2005) Using life cycle assessment (LCA) as a tool to enhance environmental impact assessment (Eia). Chem Engi Transact 7:521–528

Das TK, Houtman C (2004) Evaluating chemical-, mechanical-, and bio-pulping processes and their sustainability characterization using life-cycle assessment. Environ Prog 4(23):347–357

Dias A, Lopes E, Arroja L, Capela I, Pereria F (2002) Life cycle assessment of paper production from eucalyptus globulus. Case study of the Portuguese industry. Appita J 1(55):21–26

Ekvall T (1999a) Key methodological issues for life cycle inventory analysis of paper recycling. J Cleaner Prod 4(7):281–294

Ekvall T (1999b) System expansion and allocation in life cycle assessment—with implications for wastepaper management. Ph.D. thesis, Chalmers University of Technology, Sweden

Ekvall T, Andrae ASG (2006) Attributional and consequential environmental assessment of the shift to lead-free solders. Int J Life Cycle Assess 5(11):344–353

Ekvall T, Tillman A-M (1997) Open-loop recycling: criteria for allocation procedures. Int J Life Cycle Assess 3(2):155–162

Ekvall T, Weidema BP (2004) System boundaries and input data in consequential life cycle inventory Analysis. Int J Life Cycle Assess 3(9):161–171

Fu GZ, Chan AW, Minns DE (2005) Preliminary assessment of the environmental benefits of enzyme bleaching for pulp and paper making. Int J Life Cycle Assess 2(10):136–142

Gaudreault C, Samson R, Stuart PR (2007a) Life-cycle thinking in the pulp and paper Industry. Part I: current practices and most promising avenues. Tappi J 7(6):25–31

Gaudreault C, Samson R, Stuart PR (2007b) Life-cycle thinking in the pulp and paper industry. Part 2: LCA studies and opportunities for development. Tappi J 8(6):3–10

Guinee JB, Heijungs R, Huppes G (2004) Economic allocation: examples and derived decision tree. Int J Life Cycle Assess 1(9):23–33

ISO (2006a) Environmental management–life cycle assessment—principles and framework. ISO 14040. International Organization for Standardization, Geneva

ISO (2006b) environmental management–life cycle assessment—requirements and guidelines. ISO 14044. International Organization for Standardization, Geneva

Janssen M, Cornejo F, Stuart PR (2006) Techno-economic considerations for dip production increase and implementation of cogeneration at an integrated newsprint mill. Pulp Pap-Canada 9(107):33–37

Lesage P, Ekvall T, Deschênes L, Samson R (2007a) Environmental assessment of Brownfield rehabilitation using two different life cycle inventory models—Part 1: methodological approach. Int J Life Cycle Assess 6(12):391–398

Lesage P, Ekvall T, Deschênes L, Samson R (2007b) Environmental assessment of Brownfield rehabilitation using two different life cycle inventory models—Part 2: case study. Int J Life Cycle Assess 7(12):497–513

Lopes E, Dias A, Arroja L, Capela I, Pereira F (2003) Application of life cycle assessment to the Portuguese pulp and paper industry. J Cleaner Prod 1(11):51–59

Munoz I, Rieradevall J, Torrades F, Peral J, Domenech X (2006) Environmental assessment of different advanced oxidation processes applied to a bleaching kraft mill effluent. Chemosphere 1(62):9–16

Palmer K, Sigman H, Walls M (1997) The cost of reducing municipal solid waste. J Environ Econ Manag 2(33):128–150

Rehnstrom C (2003) LCA of two chemical recovery processes in the pulp industry—a case study. Nord Pulp Pap Res J 3(18):344–354

Salazar Zarate ES (2004) Life cycle assessment (LCA) of newsprint production at an integrated mill. Ecole Polytechnique, Montreal

Scheringer M, Halder D, Hungerbuhler K (2000) Comparing the environmental performance of fluorescent whitening agents with peroxide bleaching of mechanical pulp. J Indust Ecol 4(3):77–85

Tillman A-M (2000) Significance of decision-making for LCA methodology. Environ Impact Asses 1(20):113–123

Vizcarra A, Lo V, Bicho PA, Watson PA (1999) A cradle-to-gate life cycle assessment of straw pulp incorporation into telephone directory-grade paper. TAPPI J 2(82):115–122

Vogtlander JG, Brezet HC, Hendriks CF (2001) Allocation in recycling systems—an integrated model for the analyses of environmental impact and market value. Int J Life Cycle Assess 6(6):344–355

Weidema BP (2003) Market information in life cycle assessement. Danish Environmental Protection Agency, Copenhagen

Weidema BP, Frees N, Nielsen A-M (1999) Marginal production technologies for life cyle inventories. Int J Life Cycle Assess 1(4):48–56

Yamada H, Daigo I, Matsuno Y, Adachi Y, Kondo Y (2006) Application of Markov chain model to calculate the average number of times of use of a material in society—an allocation methodology for open-loop recycling. Int J Life Cycle Assess 5(11):354–360

Acknowledgements

This project was supported by Natural Sciences and Engineering Research Council of Canada (NSERC).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Rita Schenk

Rights and permissions

About this article

Cite this article

Gaudreault, C., Samson, R. & Stuart, P.R. Energy decision making in a pulp and paper mill: selection of LCA system boundary. Int J Life Cycle Assess 15, 198–211 (2010). https://doi.org/10.1007/s11367-009-0125-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-009-0125-1