Abstract

Background, aim and scope

Different ways of performing a life cycle assessment (LCA) are used to assess the environmental burden of milk production. A strong connection exists between the choice between attributional LCA (ALCA) and consequential LCA (CLCA) and the choice of how to handle co-products. Insight is needed in the effect of choice on results of environmental analyses of agricultural products, such as milk. The main goal of this study was to demonstrate and compare ALCA and CLCA of an average conventional milk production system in The Netherlands.

Materials and methods

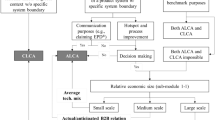

ALCA describes the pollution and resource flows within a chosen system attributed to the delivery of a specified amount of the functional unit. CLCA estimates how pollution and resource flows within a system change in response to a change in output of the functional unit. For an average Dutch conventional milk production system, an ALCA (mass and economic allocation) and a CLCA (system expansion) were performed. Impact categories included in the analyses were: land use, energy use, climate change, acidification and eutrophication. The comparison was based on four criteria: hotspot identification, comprehensibility, quality and availability of data.

Results

Total environmental burdens were lower when using CLCA compared with ALCA. Major hotspots for the different impact categories when using CLCA and ALCA were similar, but other hotspots differed in contributions, order and type. As experienced by the authors, ALCA and use of co-product allocation are difficult to comprehend for a consequential practitioner, while CLCA and system expansion are difficult to comprehend for an attributional practitioner. Literature shows concentrates used within ALCA will be more understandable for a feeding expert than the feed used within CLCA. Outcomes of CLCA are more sensitive to uncertainties compared with ALCA, due to the inclusion of market prospects. The amount of data required within CLCA is similar compared with ALCA.

Discussion

The main cause of these differences between ALCA and CLCA is the fact that different systems are modelled. The goal of the study or the research question to be answered defines the system under study. In general, the goal of CLCA is to assess environmental consequences of a change in demand, whereas the goal of ALCA is to assess the environmental burden of a product, assuming a status-quo situation. Nowadays, however, most LCA practitioners chose one methodology independent of their research question.

Conclusions

This study showed it is possible to perform both ALCA (mass and economic allocation) and CLCA (system expansion) of milk. Choices of methodology, however, resulted in differences in: total quantitative outcomes, hotspots, degree of understanding and quality.

Recommendations and perspectives

We recommend LCA practitioners to better distinguish between ALCA and CLCA in applied studies to reach a higher degree of transparency. Furthermore, we recommend LCA practitioners of different research areas to perform similar case studies to address differences between ALCA and CLCA of the specific products as the outcomes might differ from our study.

Similar content being viewed by others

1 Introduction

In The Netherlands, over the period from 2001 to 2005, on average 10.7 million tons of milk per year was produced (BINternet 2003). This milk was produced on mostly specialised dairy farms (24,400 in 2001 and 20,810 farms in 2005) that made use of many inputs, such as concentrates (BINternet 2003). The production of milk causes environmental side effects, such as emission of greenhouse gases and nutrient enrichment in surface water. The Dutch society pays much attention to ecological sustainability of milk production (Van Calker et al. 2005). Life cycle assessment (LCA) was identified to be a useful tool to assess the integral environmental impact of different milk production systems (Thomassen and De Boer 2005). Although guidelines are given on how to perform an LCA, differences among studies still exist due to different methodological choices.

Two different LCA approaches, attributional LCA (ALCA) and consequential LCA (CLCA), were identified and described (Heijungs 1997; Frischknecht 1998; Ekvall 1999; Tillman 2000; Weidema 2003). ALCA describes the pollution and resource flows within a chosen system attributed to the delivery of a specified amount of the functional unit (Rebitzer et al. 2004). CLCA estimates how pollution and resource flows within a system change in response to a change in output of the functional unit (Ekvall and Weidema 2004; Rebitzer et al. 2004).

When performing an LCA, in most cases, multi-functional processes are included in the analysed system. Choices of how to handle co-products, therefore, are inevitably connected with performing an LCA. The distinction between ALCA and CLCA was developed in the process of resolving the methodological debates over allocation problems and the choice of data. A strong connection, therefore, exists between the choice of ALCA and CLCA and the choice of how to handle co-products. Within ALCA, avoiding allocation by using system expansion to handle co-products is optional, while co-product allocation is most frequently used. Avoiding allocation by system expansion, however, is the only way to deal with co-products within CLCA, as it reflects the consequences of a change in production (Weidema 2003).

In previous LCA studies of milk production performed in different European countries, mostly ALCA was used and some kind of allocation (mass, energy-based or economic; Høgaas Eide 2002; Hospido et al. 2003; Casey and Holden 2005; Thomassen et al. 2008). Cederberg and Stadig (2003) applied system expansion within ALCA when dividing the environmental burden of the organic milk production system between milk and the co-products of meat and surplus calves. Only Nielsen et al. (2005) applied CLCA including system expansion for the Danish conventional milk production system. Obviously, LCA practitioners choose between ALCA and CLCA and different ways of how to handle co-products. However, it is not clear what the effects of these choices are on outcomes. Insight is needed in the effect of this choice on results of environmental analyses of agricultural products, such as milk. The goal of this study is to demonstrate and compare ALCA (using mass and economic allocation) and CLCA (using system expansion) of an average conventional milk production system in The Netherlands. The comparison was based on four criteria: hotspot identification, comprehensibility, quality and availability of data.

2 Goal and scope definition

The chosen functional unit was ‘1 kg of fat and protein-corrected milk (FPCM) leaving the farm gate.’ This study was a cradle-to-farm gate LCA. The included impact categories were: land use, energy use, climate change, acidification and eutrophication. The following life cycle impact assessment methods were used: (1) the EDIP 97 method (updated version 2.3; Wenzel et al. 1997) and (2) the cumulative energy demand (VDI 1997). Both methodologies were implemented in the PC-tool SimaPro 7.

The comparison between both methodologies was based on four criteria. These criteria were derived from effectiveness assessments to evaluate environmental indicators (Thomassen and De Boer 2005; Cornelissen 2003). Furthermore, hotspot identification was included, as this is an important aspect of an LCA. All four criteria were related to this specific study of milk production. Hotspot identification implies identification of elements within the system that contribute most to a certain impact category. Differences in hotspots were assessed. Comprehensibility was assessed by looking at the degree of difficulty in understanding by LCA practitioners, based on discussions among the authors, and by feeding experts, based on literature. To assess quality, the reliability of the results was evaluated by looking at uncertainties. The availability of data was assessed by looking at the amount of data required.

3 Inventory

Table 1 shows the setup of the average conventional milk production system based on data of 286 conventional farms in The Netherlands from the year 2003 (BINternet 2003). The system was simplified by assuming that farms were partly self-sufficient. This means no animals, roughage and organic fertiliser were purchased. In addition, it was assumed that no roughage and organic fertiliser were conveyed, so the only two outputs were milk and animals (mostly bull calves and milking cows).

3.1 Attributional life cycle inventory

Figure 1 shows the ALCA flowchart of the system based on average historical data. ALCA reflects the environmental impact accounted for by the system. An electricity mix for The Netherlands was used (ecoinvent Centre 2004). Purchased concentrates were related to three groups of concentrates with different protein and energy contents (Ter Veer 2005). Each group of concentrates had a different composition based on national data from the feed industry (Doppenberg and de Groot 2005). The life cycle inventory of each ingredient was assessed including cultivation, processing and transport. Capital goods, seeds and medicines were excluded.

3.1.1 Mass and economic allocation

Figure 1 also indicates where the allocation of co-products is encountered. Allocation problems occur when concentrate ingredients are part of a multi-functional process and when dividing the environmental burden between milk and animals. Mass allocation was applied by computing the share in quantity of a product. Economic allocation was applied by computing the share in proceeds of a product by taking into account quantity and economic value of the products. Table 2 shows the mass and economic allocation factors used. Table 2 shows some products, such as maize gluten meal and soy hulls, had a low allocation, which means a small amount of the environmental burden related to the main and co-product is ascribed to the co-product.

3.2 Consequential life cycle inventory

Figure 2 shows the CLCA flowchart of the system based on marginal data. CLCA reflects the possible future environmental impact from a change in demand of the product under study. The size of change in demand was an increase in milk production, which needed at least one more dairy farm. Marginal data were used, which means that data representing technologies are expected to be affected most by this increase (Schmidt and Weidema 2008). The most sensitive process is the most competitive in a situation with an increasing or constant market trend, while it is the least competitive in a situation with a decreasing market trend. In the case of electricity (marginal input), the question to be asked is: What kind of electricity plant will be installed as a result of the current increase in demand for electricity in The Netherlands? After contacting the sector and taking into account production costs, the next power plant in The Netherlands was identified to be a natural gas power plant. In the case of feed, the question to be asked is: Which feed ingredient will meet the increased protein demand as a result of the increased milk production? In addition, which feed ingredient will meet the increased energy demand as a result of the increased milk production? Taking into account the market trend, production volume and price, the marginal fodder protein was identified as soybean meal (Dalgaard et al. 2008; Schmidt and Weidema 2008). The life cycle inventory of soybeans was based on the production in Argentina, as the area covered with soybeans expanded from 6 million hectares in 1996 to 14.2 million in 2004. Furthermore, Argentina is projected to have the highest increase in export until 2014 (Pengue 2006; FAPRI 2007).

According to Weidema (2003), barley has the lowest gross margin and will be the marginal fodder energy on the European market, whereas wheat will be the marginal fodder energy on the global market. Nielsen et al. (2005) identified the marginal spring barley producer using an economic equilibrium model. We used this LCI as marginal fodder energy input, supplemented with transport to The Netherlands (Dalgaard et al. 2008).

The following formulas were used to compute the purchased amounts.

where

- VEM:

-

Dutch system that represents feed energy value (in VEM/kg DM where one VEM is 6.9 kJ of net energy; Van Es 1978)

- \({\text{VEM}}_{{{\text{requirement}}}} \) :

-

\({\sum\limits_{\text{i}} {{\text{animals}}_{i} } } \times {\text{VEM}}{\left( {{\text{maintenance + milk production + growth}}} \right)}_{{\text{i}}} \)

- \({\text{VEM}}_{{{\text{on - farm produced}}}} \) :

-

\({\sum\limits_{\text{j}} {{\text{yield}}_{j} } } \times {\text{area}}_{j} {\text{VEM}}{\left( {{\text{crop production}}} \right)}_{j} \)

- i :

-

different animals; calves, heifers, dairy cows

- j :

-

yield of different feed crops; grass, maize, and grain given in kilograms dry matter per hectare, area in hectares and VEM crop production given in VEM per kilogram dry matter. Concerning fresh grass intake, the amount of pasture days (185 for dairy cows) and grazing system (restricted for dairy cows) were taken into account.

$${\text{DVE}}_{{\text{requirement}}} - {\text{DVE}}_{{\text{on - farm}}\,{\text{produced}}} {\text{ = DVE}}_{{\text{spring}}\,{\text{barley}}} + \,{\text{DVE}}_{{\text{soybean}}\,{\text{meal}}} $$(2)

where

- DVE:

-

Dutch system that represents intestine digestible protein content; unit is kilograms (Tamminga et al. 1994; Van Straalen 1995)

- \({\text{DVE}}_{{{\text{requirement}}}} \) :

-

\({\sum\limits_{\text{i}} {{\text{animals}}_{i} } } \times {\text{DVE}}{\left( {{\text{maintenance + milk production + growth}}} \right)}_{{\text{i}}} \)

- \({\text{DVE}}_{{{\text{on - farm produced}}}} \) :

-

\({\sum\limits_{\text{j}} {{\text{yield}}_{j} } } \times {\text{area}}_{j} \times {\text{DVE crop production}}_{j} \)

- i :

-

different animals; calves, heifers and dairy cows

- j :

-

yield different feed crops; grass, maize, grain given in kilograms dry matter per hectare, area in hectares and DVE crop production given in DVE per kilogram dry matter. Concerning fresh grass intake, amount of pasture days (185 for dairy cows) and grazing system (restricted for dairy cows) were taken into account.

3.2.1 System expansion

The procedure known as system expansion means that the boundaries of the system investigated are expanded to include the alternative production of exported functions. To include the alternative way of production, a competing product with a similar function must be identified to represent indirect effects of the exported functions (Ekvall and Finnveden 2001). This procedure reflects as closely as possible the consequences of a specific change in demand for a co-product (Weidema and Norris 2002). Guinée et al. (2002) added to this definition, based on Tillman et al. (1994), not to add functions but to subtract them from those alternatives providing additional functions, the so-called substitution or avoided-burden method. When system expansion is performed, the environmental load of the avoided burden in most studies is subtracted. In this study, when using the system expansion method, we implement it as an avoided-burden method.

System expansion was applied whenever a multifunctional process had more than one functional flow. Figure 2 shows the avoided products when the chosen increase in milk production (at least one more dairy farm is needed) occurs.

For example, soybean meal has the co-product soybean oil. Therefore, increased demand for soybean meal leads to increased production of soybean oil, which substitutes palm oil, as Fig. 2 shows. However, when less palm oil is produced, also less palm kernel meal is produced. To compensate for this ‘missing’ palm kernel meal, more soybean meal should be produced. Both soybean meal and palm kernel meal are used as feed for livestock. According to Fig. 2, the avoided production of palm kernel meal is compensated by both soybean meal and spring barley production. This is because the substitution ratio is based on both energy and protein content of the meal, and as the protein and energy content differs between palm kernel meal and soybean meal, part of the palm kernel meal is substituted by spring barley. For more details, see Dalgaard et al. (2008).

The milk system was also expanded because milk is associated with the co-product of beef. When identifying the avoided burden of meat from dairy cows, the question to be asked was: What will not be purchased by retailers/supermarkets when more meat from dairy cows is provided? After contacting the sector, it was identified that this increased availability of beef will replace that from foreign dairy cows and pork, as meat from dairy cows is mainly used for minced meat and easy-to-prepare meat meals (Rang and Westra 2006). Meat from foreign and domestic dairy cows, however, is constrained by quotas, and therefore, the marginal meat must come from beef cattle and pigs. However, calves, mostly bulls, are an output of the milk system as well and will result in beef production after a growth period at a meat cattle farm. It was assumed, therefore, that beef (both from calves and dairy cows) substituted beef and pork. These data on beef and pork production were based on Danish CLCAs (Nielsen et al. 2005).

4 General overview of ALCA and CLCA outcomes

Table 3 shows the characterised results of the average conventional milk production system using ALCA and mass and economic allocation, besides CLCA and system expansion. Table 3 shows that when using mass or economic allocation within ALCA, total environmental burdens were influenced slightly. Furthermore, energy use computed by CLCA was only 35−45% of energy use found by ALCA. Acidification computed by CLCA was around 40% of acidification by ALCA, climate change 55−60%, eutrophication 65−70% and land use 75−80%. These lower values of CLCA are mainly caused by the subtraction of avoided burdens of identified alternative products. Avoided beef production was the main cause of the lower land use, while difference in feed type within ALCA (three concentrates with different compositions) and CLCA (spring barley and soybean meal) was the main cause of the lower energy use. Both avoided beef production and difference in feed type within ALCA and CLCA caused lower acidification, eutrophication and climate change.

5 Comparison

The comparison of ALCA and CLCA in milk production was based on four criteria: hotspot identification, comprehensibility, quality and availability of data. Table 4 provides an overview of the main characteristics of ALCA and CLCA (Guinée et al. 2002; Weidema 2003) complemented with the comparison outcomes. Below, the outcomes of the comparison are discussed.

5.1 Hotspot identification

Hotspot identification implies identification of elements within the system that contribute most to a certain impact category. Environmental hotspots of conventional milk production, for the different impact categories, were identified with a contribution analysis. The impact category climate change is highlighted by means of an illustration. The hotspots of the other impact categories are presented in Sections 5.1.2 to 5.1.5.

5.1.1 Climate change

Figure 3a shows the contribution of different processes in the conventional milk production system to climate change expressed in global warming potential (GWP) of ALCA using both mass and economic allocation. Figure 3b shows the contribution of different processes in the conventional milk production system to climate change of CLCA using system expansion. Both figures show that emissions related to keeping animals and feed production at the dairy farm (mainly methane and nitrous oxide) contributed most to climate change when using ALCA and CLCA.

Contribution of different processes to climate change expressed in GWP of conventional milk production by ALCA using both mass and economic allocation (a) and by CLCA using system expansion (b). The category at dairy farm implies emissions related to keeping animals and on-farm feed production. The category fertiliser (N) at dairy farm implies related emissions to production and transport of fertiliser (N) purchased by the dairy farm. The category fertiliser (N) off-farm implies related emissions to production and transport of fertiliser (N) used for production of crops that were used as concentrates ingredients. The categories transport truck and freighter oceanic imply transport of feed. The categories maize gluten meal and soy hulls and spring barley imply cultivation and production process. The category soybean meal implies cultivation and production of soybean meal including avoided production of palm oil

Within CLCA, only the concentrates ingredients spring barley and soybean meal were used, while within ALCA, many ingredients were used, of which maize gluten meal and soy hulls were the main contributing ingredients to GWP. Maize gluten meal and soy hulls contributed for 30% (economic allocation) and 18% (mass allocation) to GWP (see Fig. 3a), while soybean meal and spring barley contributed for 27% to GWP (see Fig. 3b). Within CLCA, the avoided beef production was higher than the avoided pork production, mainly due to methane emissions from beef cows.

5.1.2 Land use

The area covered by the dairy farm had the highest contribution to total land use both within CLCA and ALCA. Within CLCA, the other hotspots were spring barley and soybeans, while within ALCA, the other hotspots were related to feed as well: soybeans, maize grain, sugar beets and fresh fruit bunches. Within CLCA, the avoided beef production was higher than avoided pork, soy and palm production.

5.1.3 Energy use

Within both CLCA and ALCA, the identified hotspots were diesel, transport by truck, electricity and natural gas. The only difference was that, within CLCA, electricity was based on generation in a natural gas power plant and, within ALCA, it was based on a mixture of generators.

5.1.4 Acidification

Emissions from the dairy farm contributed most to the acidification potential both within CLCA and ALCA. Within CLCA, the other hotspots were spring barley, transport by ship, energy and N fertiliser. Within ALCA, they were transport (both truck and freighter oceanic), diesel use, maize grain and N fertiliser. Within CLCA, the avoided beef production was higher than the avoided pork and palm production.

5.1.5 Eutrophication

Emissions and leaching at the dairy farm contributed the most to the eutrophication potential both within CLCA and ALCA. Within CLCA, the other hotspot was spring barley. Within ALCA, they were maize grain, sugar beets, rape seed and soybeans. Within CLCA, the avoided beef production was higher than the avoided pork and palm production.

5.2 Comprehensibility

Degree of comprehensibility was assessed by looking at the degree of difficulty in understanding by LCA practitioners, based on discussions among the authors and by feeding experts, based on literature.

The goal of ALCA is to assess the environmental burden of a product, assuming a status-quo situation, whereas the goal of CLCA is to assess the environmental consequences of a change in demand. ALCA requires a physical-accounting way of thinking, whereas CLCA requires a physical-accounting and economic-causal way of thinking. A consequential practitioner asks him/herself which processes are affected when a change in demand of the product under study occurs. The authors experienced that it was difficult for an attributional practitioner to understand how it is possible to include future processes in the analyses. For example, it is difficult to understand that the required electricity to produce the increased amount of the product under study is based on one power plant (the marginal one), instead of on an electricity mix. Furthermore, when performing system expansion within CLCA, it is difficult for an attributional practitioner to understand why and how to include avoided processes in the analyses (Heijungs and Guinée 2007). On the other hand, the authors experienced that it was difficult for a consequential practitioner to understand that, within ALCA, market mechanisms and size of change in demand are ignored; the processes included within ALCA are not the processes affected by a change. Furthermore, using arbitrary allocation factors for dividing the environmental burden of a product, as a practical solution to overcome a technical obstacle, is difficult to understand for a consequential practitioner. Using a factor based on monetary values or physical amounts to divide the environmental burden over different products, while the environmental burdens of byproducts are excluded, is not in line with their economic-causal way of thinking. Conclusively, as experienced by the authors, ALCA and the use of co-product allocation are difficult to comprehend for a consequential practitioner, while CLCA and system expansion are difficult to comprehend for an attributional practitioner.

Feeding experts usually try to optimise growth and milk production by meeting the needs of the dairy cow. Nutritional and health aspects are important aspects that the feeding industry takes into consideration when composing concentrates (Goff 2006; Eastridge 2006). Within ALCA, real-life data of concentrates composition are used, which represents the requirements of the animals to produce milk. Within CLCA, energy and protein requirements are used to calculate the necessary amounts of spring barley and soybean meal to meet these needs (see Section 3.2). Although energy and protein requirements are the most important aspects to consider, a feed ratio based on a diet composed of only two ingredients, besides grass and maize silage intake produced on farm, might imply a loss of production, due to an unbalanced diet, especially when used over the long term, and is not recommended by feeding experts (Morrison and Patterson 2007). Using soybean meal as the only protein ingredient, however, is supported by the strong connection between the world’s expanding livestock sector and the expanding soybean area in South America (Steinfeld et al. 2006). At this moment, it seems as if soybean will become increasingly important in the future as it is the most competitive protein source on the world market (Dalgaard et al. 2008) and because a still larger part of the livestock feed is soybean meal (Steinfeld et al. 2006). Despite this increasing use of soybean meal as a protein source, concentrates used within ALCA will be more understandable for a feeding expert compared with the feed used within CLCA, as it represents a realistic situation.

5.3 Quality

When analysing the reliability over time and individuals, we want to assess uncertainties. Every time an LCA is performed, uncertainties are included. Within ALCA, average data are used, and in most cases, uncertainties can be quantified. Examples are variations around ammonia emissions and nitrate leaching. When identifying marginal technologies within CLCA, with a market prospect of, at the highest, 15 years, another uncertainty is brought into the analyses. Uncertain knowledge is used to predict future consequences. Within CLCA, this uncertainty can be quantified by performing sensitivity analysis with several alternative market situations. For instance, if we look at the marginal electricity supplier in The Netherlands, we identify the natural gas power plant. If the marginal electricity supplier was identified to be a wind power plant, outcomes would have been different, so sensitivity analyses are needed. In general, it can be concluded that outcomes of CLCA are more sensitive to uncertainties compared with ALCA, due to the inclusion of market prospects.

5.4 Availability of data

At first sight, CLCA seemed to decrease the amount of data required. In the case of concentrates, data on only two ingredients were needed (protein-rich and energy-rich), while, within ALCA, data on all ingredients of different concentrates were needed. However, when applying system expansion, the system is expanded, and new data are needed each time. For instance, in case of milk production, the marginal pork production was included. Therefore, data on pork production were suddenly needed when analysing milk production systems. The underlying theory is that data collection is lower within CLCA because some constrained processes are not linked, since these cannot change their output in response to a change in demand. Market data, however, are an additional data requirement for CLCA. Lack of marginal data is a problem when performing CLCA, which is probably due to the current small number of consequential practitioners. More research is needed to identify marginal processes.

In this study, it can be concluded that the amount of data required within CLCA is similar compared with ALCA. On the one hand, less data are required within CLCA compared with ALCA, while on the other hand, marginal data are not always available, and performing system expansion often implies the use of data on new processes within CLCA. In LCAs of products other than milk, however, differences in data requirement might exist.

6 Discussion and conclusions

This article demonstrates how to perform ALCA (mass and economic allocation) and CLCA (system expansion) of an average conventional milk production in The Netherlands. Furthermore, this study presents an overview of the main differences between the two methodologies, ALCA and CLCA, when analysing a conventional milk production system.

Usage of allocation factors within ALCA and usage of system expansion within CLCA correspond with the International Standards Organization (ISO) standards (ISO 2006). According to these standards, the first option is to avoid allocation by making use of a subdivision or to expand the systems investigated. The second option is to allocate based on physical causal relationships between the environmental burdens and functions. The third and last option is to allocate according to relationships other than the physical causal. Applying system expansion within CLCA agrees with the first option given in the ISO standards. Applying some kind of allocation is not the first option given in the ISO standards. Applying system expansion within ALCA requires an economic-causal way of thinking. The authors experienced it was hard to perform system expansion within ALCA, as no change in demand is assumed, and therefore, it is hard to assess avoided burdens in a correct way. Both mass and economic allocations were applied within ALCA, which resulted in a small difference in total environmental burden. Although applying mass allocation is given preference over applying economic allocation according to ISO standards, in most studies, economic allocation is used within ALCA. One argument for using economic allocation is that the value of co-products represents the causal factor for the production process.

Differences were found between ALCA and CLCA in total quantitative outcomes, hotspots, degree of understanding by various stakeholders and quality. Total outcomes computed by CLCA were only 35–75% of outcomes computed by ALCA, different per impact category. Major hotspots were the same for all impact categories, computed by ALCA and CLCA, whereas the other hotspots differed in contribution, order and type. As experienced by the authors, ALCA and the use of co-product allocation are difficult to comprehend for a consequential practitioner, while CLCA and system expansion are difficult to comprehend for an attributional practitioner. Furthermore, literature shows concentrates used within ALCA will be more understandable for a feeding expert than the feed used within CLCA. Outcomes of CLCA are more sensitive to uncertainties as compared with ALCA, due to the inclusion of market prospects.

The main cause of these differences between ALCA and CLCA is the fact that different systems are modelled. The goal of the study or the research question to be answered defines the system under study. In general, the goal of CLCA is to assess consequences of a change in demand, whereas the goal of ALCA is to assess the environmental burden of a product, assuming a status-quo situation. Nowadays, however, most LCA practitioners choose one methodology independent of their research question. Only Ekvall and Andræ (2006) used both ALCA and CLCA to assess climate change when shifting from a tin–lead wave solder paste to a lead-free reflow solder paste. Due to lack of marginal data, average data was used besides the marginal data in the consequential LCI. Both methods showed the shift in solder paste resulted in reduced lead emissions and an increased GWP. Differences, however, were found in total quantitative outcomes and contribution of hotspots, which agree with the findings in our study.

7 Recommendations

We recommend that LCA practitioners better distinguish between ALCA and CLCA in applied studies to reach a higher degree of transparency. Furthermore, we recommend that LCA practitioners of different research areas perform similar case studies to address differences between ALCA and CLCA of the specific products, as the outcomes might differ from those in our study.

References

BINternet (2003) Bedrijven-InformatieNet. Available at: http://www.lei.wur.nl/UK

Casey JW, Holden NM (2005) Analysis of greenhouse gas emissions from the average Irish milk production system. Agric Syst 86:97–114

Cederberg C, Stadig M (2003) System expansion and allocation in life cycle assessment of milk and beef production. Int J LCA 8:350–356

Cornelissen AMG (2003) The two faces of sustainability. Fuzzy evaluation of sustainable development. Ph.D. thesis, Animal Production Systems Group,Wageningen University, The Netherlands, pp 1–184

Dalgaard R, Schmidt J, Halberg N, Christensen P, Thrane M, Pengue WA (2008) LCA of soybean meal. Int J LCA 13(3):240–254

Doppenberg J, de Groot JP (2005) Lineaire programmering rundvee-, varkens- en pluimveevoeders. VVM Bedrijfsbureau; Vereniging Voorlichting Mengvoerindustrie, Deventer, The Netherlands

Eastridge ML (2006) Major advances in applied dairy cattle nutrition. J Dairy Sci 89:1311–1323

ecoinvent Centre (2004) Ecoinvent data v1.1. Final reports Ecoinvent 2000 (1–15). Swiss Centre for Life Cycle Inventories, Duebendorf (CD-ROM)

Ekvall T (1999) System expansion and allocation in life cycle Assessment; with implications for wastepaper management. Department of Technical Environmental Planning, Chalmers University of Technology, Goteborg, Sweden, pp 1–54

Ekvall T, Finnveden G (2001) Allocation in ISO 14041—a critical review. J Clean Prod 9:197–208

Ekvall T, Weidema BP (2004) System boundaries and input data in consequential life cycle inventory analysis. Int J Life Cycle Assess 9:161–171

Ekvall T, Andræ ASG (2006) Attributional and consequential environmental assessment of the shift to lead-free solders. Int J LCA 11:344–353

FAPRI (2007) Food and Agricultural Policy Research Institute. Available at: http://www.fapri.org

Frischknecht R (1998) Life cycle inventory analysis for decision-making. Swiss Federal Institute of Technology, Zurich, Switzerland

Goff JP (2006) Major advances in our understanding of nutritional influences on bovine health. J Dairy Sci 89:1292–1301

Guinée JB, Gorrée M, Heijungs R, Huppes G, Kleijn R, de Koning A, van Oers L, Wegener Sleeswijk A, Suh S, Udo de Haes HA, de Bruijn H, van Duin R, Huijbregts MAJ, Lindeijer E, Roorda AAH, van der Ven BL, Weidema BP (eds) (2002) Handbook on life cycle assessment. Operational guide to the ISO standards. Centrum voor Milieukunde, Universiteit Leiden (CML). Kluwer, Leiden, The Netherlands

Heijungs R (1997) Economic drama and the environmental stage formal derivation of algorithmic tools for environmental analysis and decision-support from a unified epistemological principle. Centre of Environmental Science, Leiden University, Leiden

Heijungs R, Guinée JB (2007) Allocation and ‘what-if’ scenarios in life cycle assessment of waste management systems. Waste Manage 27:997–1005

Høgaas Eide M (2002) Life cycle assessment (LCA) of industrial milk production. Int J LCA 7:115–126

Hospido A, Moreira MT, Feijoo G (2003) Simplified life cycle assessment of Galician milk production. Int Dairy J 13:783–796

ISO (2006) Environmental management. The ISO 14000 family of international standards. Available at: http://www.iso.org

Morrison SJ, Patterson DC (2007) The effects of offering a range of forage and concentrate supplements on milk production and dry matter intake of grazing dairy cows. Grass Forage Sci 62:332–345

Nielsen PH, Nilesen AM, Weidema BP, Dalgaard R, Halberg N (2005) LCA food database. Available at: http://www.lcafood.dk/database

Pengue WA (2006) Increasing roundup ready soybean export from Argentina. In: Halberg NAH, Knudsen MT, Kristensen ES (eds) Global development of organic agriculture. CABI, Oxfordshire, UK, p 20

Rang H, Westra PP (2006) Prijsopbouw rundvlees. PVE; Productschappen Vee, Vlees en Eieren, Zoetermeer, p 1–16

Rebitzer G, Ekvall T, Frischknecht R, Hunkeler D, Norris G, Rydberg T, Schmidt WP, Suh S, Weidema BP, Pennington DW (2004) Life cycle assessment. Part 1: framework, goal and scope definition, inventory analysis, and applications. Environ Int 30:701–720

Schmidt JH, Weidema BP (2008) Shift in the marginal supply of vegetable oil. Int J LCA 13(3):235–239

Steinfeld H, Gerber P, Wassenaar T, Castel V, Rosales M, de Haan C (2006) Livestock’s long shadow; environmental issues and options. Food and Agricultural Organization of the United Nations, Rome, Italy

Tamminga S, Van Straalen WM, Subnel APJ, Meijer RGM, Steg A, Wever CJG, Blok MC (1994) The Dutch protein evaluation system: The DVE/OEB-system. Livest Prod Sci 40:139–155

Ter Veer DF (2005) Scenariostudie 100% biologisch voeren melkvee. Animal Sciences Group/Praktijkonderzoek, Lelystad, pp 1–22

Thomassen MA, de Boer IJM (2005) Evaluation of indicators to assess the environmental impact of dairy production systems. Agric Ecosyst Environ 111:185–199

Thomassen MA, Van Calker KJ, Smits MCJ, Iepema GL, De Boer IJM (2008) Life Cycle Assessment of conventional and organic milk production in The Netherlands. Agric Syst 96:95–107

Tillman A-M (2000) Significance of decision-making for LCA methodology. Environ Impact Assess Rev 20:113–123

Tillman A-M, Ekvall T, Baumann H, Rydberg T (1994) Choice of system boundaries in life cycle assessment. J Clean Prod 2:21–29

Van Calker KJ, Berentsen PBM, Giesen GWJ, Huirne RBM (2005) Identifying and ranking attributes that determine sustainability in Dutch dairy farming. Agric Human Values 22:53–63

Van Es AJH (1978) Feed evaluation for ruminants 1. The systems in use from May 1977 onwards in The Netherlands. Livest Prod Sci 5:331–345

Van Straalen WM (1995) Modelling of nitrogen flow and excretion in dairy cows. Department of Animal Nutrition, Wageningen University and Research Centre, Wageningen, pp 1–205

VDI (1997) Cumulative energy demand—terms, definitions, methods of calculation. In: Ingenieure VD. VDI-Richtlinien 4600, Düsseldorf, Germany

Weidema BP (2003) Market information in life cycle assessment. Danish Environment Protection Agency, Copenhagen, Denmark, pp 1–147

Weidema BP, Norris GA (2002) Avoiding co-product allocation in the metals sector. In: ICMM International Workshop on Life Cycle Assessment and Metals. Dubreuil A, Montreal, Canada, pp 81–87

Wenzel H, Hauschild M, Alting L (1997) In: Edition F (ed) Environmental assessments of products, vol 1: methodology, tools and case studies in product developments. Champan & Hall, London, UK)

Acknowledgements

Financial support for this work has been provided by the Dutch Ministry of Agriculture, Nature Conservation and Food Quality (Programme 415). We would like to thank Bo Weidema for giving structural comments on an earlier version of this paper.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Niels Jungbluth

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Thomassen, M.A., Dalgaard, R., Heijungs, R. et al. Attributional and consequential LCA of milk production. Int J Life Cycle Assess 13, 339–349 (2008). https://doi.org/10.1007/s11367-008-0007-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-008-0007-y