Abstract

Increasing globalization and climate change have significantly affected business activities. Government and other stakeholders are creating pressure to have a sustainable business model for efficient resource utilization and minimizing negative environmental impact. Many organizations have started focusing on sustainable and cleaner production through the adoption of net-zero economy (NZE) practices. Certain technological advancements are required to put these concepts into practice. Firms have begun to adopt digital technologies (such as big data analytics, artificial intelligence, and internet of things), and have been widely used in practice to achieve NZE. Is digitalization unlocking the potential of sustainable practices in the context of a net-zero economy? This question is still unanswered; therefore, this study aims to identify and analyze the drivers of digitalization that ensure sustainable practices to achieve net-zero economy. Through an extensive literature review and experts’ opinions, a list of drivers was identified. An empirical investigation was conducted to validate the identified drivers and further understand the influencing relationship among the drivers, Pythagorean fuzzy decision-making trial and evaluation laboratory (PF-DEMATEL) was employed. The findings of the study show that “high degree of automation,” “enhancing the flexibility in the manufacturing process,” and “real-time sensing capability” are the main influencer drivers among all cause group forces. The present study can be a source for industrial practitioners and academia that can provide significant guidance on how the adoption of digitalization can unlock the potential to achieve CE, which can lead us toward net-zero.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Changing climate over the globe has significantly disrupted the ecosystem and it has become hazardous for human life. Hence, it is a serious issue for various stakeholders across the globe (D’Amato et al. 2017; Sofuoğlu and Kirikkaleli 2022). The air pollutants from greenhouse gas emissions have resulted in the death of 4.2 million people (Mishra et al. 2022). As a result, minimizing emissions has become a major concern and responsibility of the entire nation (Kovacikova et al. 2021). Notably, the United Nations (UN) has come up with sustainable development goals (SDGs) that ensure a healthy society, environment, and economy. To ensure SDGs, different business sectors are striving to shift their linear traditional economy to a low-emission economy to ensure sustainable production and consumption (Tumilar et al. 2020).

Various business ventures around the globe are keen to adopt circular economy principles, especially firms in the European Union (EU) (Hong Nham and Ha 2022). In one of the reports of the European Commission, it is estimated that with the adoption of circular economy (CE) practices in manufacturing, economic gains of $ 600 billion could be achieved per year in the EU (Korhonen et al. 2018). The rapidly growing research on natural resources of energy and fossil-free fuel energy helps in reducing climate change by minimizing greenhouse gas emissions (Shahsavari and Akbari 2018; Yan et al. 2022). Also, some countries like Sweden, France, and Denmark are committing to achieving a net-zero economy by 2050 (IEA 2020). The net-zero concept is defined as “the balance between the amount of greenhouse gas produced and the amount removed from the atmosphere” (Ku et al. 2021).

Enormous action plans have been considered to achieve SDGs, such as investing in renewable sources of energy, minimizing fossil fuel consumption, and adopting digital technologies to optimize resource consumption (Kristoffersen et al. 2020). Achieving sustainability across various sectors is highly significant to sustain in the competitive market (Rejeb et al. 2022). To ensure sustainable development across industrial sectors, it is very much important to develop a net-zero economy infrastructure (Stern and Valero 2021). In this regard, a business model of a net-zero economy would be needed to achieve sustainability in the business unit (Bonsu 2020).

The shift from linear economy, i.e., the take-make-waste approach toward a CE, is increasing and becoming a strategic approach across the world. The concept of circular economy and net-zero economy are replacing linear approaches with recycling, reusing, and reducing approaches (Chauhan et al. 2022). Multiple barriers are restricting the adoption of CE practices, including but not limited to “challenges in taking back” (Govindan and Hasanagic 2018), lack of awareness in society (Tura et al. 2019), and limited technology for recycled material (Bilal et al. 2020).

Researchers have suggested that effective adoption of CE practices along with the net-zero economy concept is only possible by integrating digital technologies such as artificial intelligence, big data analytics, cyber-physical system, internet of things, additive manufacturing, and others (Ajwani-Ramchandani et al. 2021; Chauhan et al. 2022; Ha et al. 2022). Thus, many studies have agreed that the adoption of CE practices has a link with digital technologies as it ensures optimized resource utilization, predictive maintenance, tracking of products even after their end of life for recycling purposes, and many more (Chauhan et al. 2021; Kamble et al. 2018a).

Big data analytics can significantly help in achieving sustainability by collecting real-time data and analyzing them for better decision-making (Dubey et al. 2019; Chang et al. 2022). For instance, real-time data can be analyzed to forecast the demand and accordingly maintain the inventory level, which minimizes waste and ensures the shelf life of the product (Ivanov and Rozhkov 2020). Digital technologies also ensure identifying best practices for recycling and refurbishing activities, thereby minimizing or eliminating waste (Khan et al. 2021). For instance, deep learning techniques for image recognition help in improving e-waste recycling practices (Nowakowski and Pamuła 2020). Digital technologies can also be a driver for mass personalization. Artificial intelligence and internet of things (IoT) based technologies enable mass personalization and enhance customer satisfaction (Aheleroff et al. 2020). Predictive maintenance has become easy using these digital technologies to enhance the life cycle of products/machinery (Rymaszewska et al. 2017). In a nutshell, industries that are adopting digital technologies are enhancing their capabilities in production, supply chain, logistics, and recycling practices. Therefore, identifying the drivers of digital technologies to achieve sustainable practices in the context of a net-zero economy is important. Based on the review of literature, this study identifies the digitalization drivers. The identified drivers are then validated using a survey of industry practitioners and academia. Further, the shortlisted drivers were analyzed using a multi-criteria decision-making technique. In these regards, the following research questions are answered in the present study:

-

RQ1. What are the driving forces of digitalization in achieving sustainable practices in the context of a net-zero economy (NZE)?

-

RQ2. How these drivers influence each other in the adoption process of sustainable practices in the context of NZE?

To answer these research questions, this study sets some objectives, which are mentioned below:

-

To analyze the literature thoroughly to identify the possible drivers of digitalization to achieve sustainable practices in the context of NZE.

-

To shortlist the drivers of digitalization through a survey.

-

To analyze shortlisted drivers using novel multi-criteria decision-making methods.

This study focused on identifying drivers of digitalization and analyzing them with the help of multi-criteria decision-making techniques. The remaining flow of the study is as follows: in the “Literature review” section, a literature review has been discussed and possible drivers of digitalization have been identified. “Research methodology” section discusses the methodology used in this study. “Analysis and discussion” section discusses the results, and “Implications” section presents the discussion. Finally, “Conclusion” section includes the implications, conclusions, and limitations of the study.

Literature review

Digitalization in the net-zero economy

As per Brundtland and Mansour (1987), sustainable development is the implementation of new business strategies that follows the organizational needs along with the shareholders supporting and securing the resources which are required for future developments. Considerable environmental benefits can be achieved through proper actions for environmental change such as diversified and secured energy. According Sovacool (2016), significant environmental benefits could be attained by taking appropriate environmental actions, such as securing energy for a healthy environment for the future generations. Jenkins et al. (2021) discussed the net-zero structure to satisfy today’s needs and those of future generations. For controlling industrial activities, it is always better to create a net-zero infrastructure to satisfy the needs of today and the future by bringing the economy to net zero. Likewise, a net-zero economy framework will always be useful for environmental sustainability. This type of framework will always recognize sustainable development in order to achieve a balance in greenhouse gas emissions, thereby controlling global warming (Kılkış and Kılkış 2018). The definition of a net-zero economy is also addressed by other countries with a growing world population (Sachs et al. 2021; Singh et al. 2022).

Industry 4.0 denotes the fourth revolution of industries. In 2011, the term I4.0 was defined by Hannover Fair in Germany. The most frequently cited definition extracted from the literature is that I4.0 assumes the operation of IT-related connections among people and machines with the exchange of data and information (Patalas-Maliszewska and Skrzeszewska 2018). I4.0 uses the resources from multiple fields that are allowed by the massive sensors with the IoT and big data technologies which leads to modern generations of computing technologies (Wankhede and Vinodh 2022). Okorie et al. (2023) discussed the role of digital technologies in achieving a net-zero economy. The authors adopted resource-based view theory to analyze the competitive advantages achieved by manufacturing firms with a net-zero economy.

Table 1 presents the existing and current research work on digitalization in the CE.

Drivers of digitalization to achieve sustainable practices

CE transformation is a strategic priority for organizations all over the world. It is also an alternative to the traditional linear economy and works on the principle of renewal, using the materials again while reducing the waste and moving toward pollution reduction (Yuan et al. 2008). Thus, CE follows the end-of-life approach with the law of reuse, recycle, reduce, and recover. To address the issues of data unavailability and ecosystem transformation, industries should shift from a linear approach to CE. The researchers argue the key factors for CE transformation move in parallel with the digital revolution, including the utilization of big data, smart sensors, artificial intelligence, fog computing, and automation (Ingemarsdotter et al. 2020; Ajwani-Ramchandani et al. 2021; Chauhan et al. 2021). This is how the academic adoption of CE is integrated with digitalization, which facilitates predictive analytics through the product life cycle of the companies (Chauhan et al. 2021).

Digitalization is also divided into five major categories of big data analytics, IoT, cyber-physical systems, virtual reality, and machine learning (Rüßmann et al. 2016). The combination of methods of managerial skills and technology transfer toward a CE can capitalize on the possibilities. The researchers identified a gap in the literature to present the concept of CE as a basic necessity to sustain life on earth (Ghisellini et al. 2016; Geissdoerfer et al. 2017). Jarrett (2013) demonstrated the CE as a primary requirement to safeguard the resources and sustain life on earth. A CE is also defined as a driver in the economic crisis and an important resource for consumers and manufacturers (Pearce and Turner 1989). Natural resources should always be conserved. The circular system must replace the open-ended system to conserve natural resources. As per Murray et al. (2017), the authors not only identified the CE’s background but also provided some optimal solutions for the CE. The argument is that the integration of sustainability and CE will have certain environmental benefits (Yang et al. 2018). CE signifies the green revolution that results in environmental, social, and economic benefits. D’Amato et al. (2017) stated that CE is focused on resources, whereas the green revolution is focused on bio ecological processes. CE also increases the green performance by working on the recreational parts (Kadar and Kadar 2020). Machine learning can accelerate the process of CE at every stage of supply chain management (Kadar and Kadar 2020). Scientists have researched closed-loop supply chains (CLSC) and reverse logistics in connection with CE (Wilson et al. 2022). The closed-loop supply chain enhances the environmental value by returning the materials to the producers (Wilson et al. 2022). Value recovery in a CLSC includes only the organization’s supply chain and never includes other channel participants (Chauhan et al. 2022).

Digital technologies are considered to be the major enablers of CE by checking the components, products, data available, and materials used to improve decision-making in any industry culture (Antikainen et al. 2018; Nobre and Tavares 2020). Digital technologies are an inevitable part of information exchange for the circular economy of natural resources. For example, the IoT (internet of things) can enable the tracking of natural capital. Similarly, big data analytics encourages several aspects of CE waste material to be resource recycled for industrial benefits. Data analytics is used as a tool to predict the accuracy of any product, the maintenance time, and to optimize the consumption of energy (Porter and Heppelmann 2014). Cardinali and de Giovanni (2022) explore the intersection of responsible digitalization and green practices. The authors argue that responsible digitalization can be achieved by adopting green practices, which can help mitigate the negative environmental impacts of digital technologies. The authors argue that responsible digitalization is an approach to digital technology that prioritizes the ethical, social, and environmental impacts of technology, in addition to its economic benefits. The authors also note that responsible digitalization is becoming increasingly important as the use of digital technologies continues to grow and the negative impacts of these technologies become more apparent.

All these signify the contribution of CE to many business strategies, from recycling to reuse through their design process. In a nutshell, 20 prominent drivers of digitalization were identified through an extensive literature survey and have been presented in Table 2.

Research gaps

IoT can be better implemented with the combination of big data analytics, cloud computing, and artificial intelligence technologies. The concept of CE can be technologically and ecologically feasible here (Sousa-Zomer et al. 2018; Tseng et al. 2018). The main role of big data is to enable the CE to act scientifically to utilize IoT and big data for the benefit of industries that are moving toward CE (Bressanelli et al. 2021). It is specifically meant to make a smart product with additional challenges to maintain security issues. IoT can benefit in overcoming all the issues with the integration of all the technologies at the organizational level. Hence, it is a requirement to understand the potential of IoT with the integration of other technologies for CE in the organizational aspect (Rejeb et al. 2022). A net-zero economy employs sustainable manufacturing, which is in high demand and will become increasingly popular in the coming years. The circular capabilities of CE boost sustainable manufacturing. The themes introduced worldwide are to increase the sustainability of the environment. Net-zero economy and sustainability include the sub-themes of CE, IoT, big data, and cloud computing. To achieve this sustainability goal, an integrated framework combining the technologies from the basic level is required. Sustainability can be defined as the combination of people, planet, and profit (Sehnem and Oliveira 2017; Zeng et al. 2017; Manninen et al. 2018; Tseng et al. 2018; Wehner et al. 2021).

Organizations should shift from a linear economy to CE which gives different values for different resources. Wastage of resources, CO2 emissions, and misuse of energy can be minimized a lot by slowing down the processes. Renewable energy usage, technology innovation, and recycling should be highly promoted for maintaining a sustainable environment. Sustainability is seen as a symbol of a company’s social responsibility to the environment and people by reputable companies (Shevchenko et al. 2016; Geissdoerfer et al. 2017; Fernando et al. 2022). To maintain sustainability, the net-zero economy plays an important role in closing the gaps. It brings CE to a place for recycling and reuse.

Research methodology

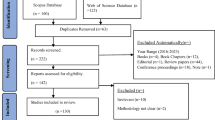

The flow of the present research study is shown in Fig. 1. First, a list of drivers of digitalization was identified from the literature review and is presented in Table 1 of the “Literature review” section. Next, the shortlisting of identified drivers and validating their relevance for the study was done using a survey-based study. A list of questionnaires was prepared corresponding to each driver and was sent to several manufacturing industries, including small-scale, medium-scale, and large-scale industries. The respondents were asked to provide a rating in the form of a Likert scale, which varies from 1 to 5 where 1 indicates strongly disagree and 5 indicates strongly agree. The survey was administered using Google Forms, and the link to the Google Form was emailed to all firm respondents on 03 May 2022. The respondents were asked to fill out their responses within a month and, after a month, a reminder mail was sent to all those firms from which responses had not yet come. Then finally, we received responses from 33 firms. Out of 33 responses, 1 response was inadequate, so 1 response was deleted, and only 32 responses were considered for further study. The profile of respondents who participated in the survey is presented in Table 3.

Table 2 depicts the list of drivers of digitalization that were identified in the literature to achieve sustainable production. The identified drivers were then circulated for validation through the survey. The responses collected from the survey were then analyzed and the mean and standard deviation of each driver were calculated and presented in Table 4.

The drivers with a mean score higher than 3 were considered for further analysis. So, from the list, out of 20 drivers only 19 drivers were validated using survey data, and one driver, namely, “Enhanced life cycle of equipment,” was not included for further study. Also, we asked the respondents to suggest any other drivers of digitalization that were not listed in the survey questionnaire. We got suggestions from respondents to add one more driver, namely, “globalization.” So, this study includes 20 drivers, of which 19 were taken from literature and one driver was suggested by experts. Finally, the selected 20 drivers were further evaluated using the Pythagorean DEMATEL approach.

Pythagorean fuzzy set theory

The bias and uncertainty in multi-criteria decision-making (MCDM) approaches can be minimized with the adoption of intuitionistic fuzzy sets (IFS) (Lahane and Kant 2021a). There are three ways to represent IFS, namely, hesitancy, membership, and non-membership function (Lahane and Kant 2021b). However, in certain instances, IFS could not manage imprecision when the degree of the membership function is greater than one. So, to avoid these issues, IFS has been integrated with three separate extensions, namely, the Pythagorean set, the neutrosophic set, and the orthopedic set (Abdullah and Goh 2019; Yazdi et al. 2020). In the present study, the Pythagorean fuzzy set was used to handle issues related to bias, uncertainty, and imprecision. All data points in the IFS, i.e., (x,y), will lie under the line X + Y ≤ 1, but in the case of the Pythagorean fuzzy set, all data points lie under the area \({X}^{2}+{Y}^{2}\le 1\). Hence, the range for the Pythagorean fuzzy set is larger than IFS. Therefore, the Pythagorean fuzzy set gives more flexibility to the decision-makers for the problem related to vagueness in decision-making. A comparison of space for the Pythagorean fuzzy set and the IFS is represented in Fig. 2. The Pythagorean fuzzy set used in this study for data collection is presented in Table 5.

Pythagorean DEMATEL

Many MCDM methods exist in the literature for solving decision-making problems. One such MCDM method is DEMATEL, which is widely used for analyzing the drivers/factors/barriers and making a causal model (Abdullah and Goh 2019; Li and Yazdi 2022a). It is considered a highly informative approach that provides useful information for cause-and-effect group factors. There are certain advantages of DEMATEL over other MCDM methods (Yazdi et al. 2020) such as:

-

It develops a digraph that helps in visualizing the structural model of factors in a decision-making problem.

-

It develops a cause-and-effect model that categorizes factors into two groups, namely, the cause group and the effect group.

-

It identifies the strength of the interrelationship between factors, which makes it more advantageous over other structural modeling approaches (Li and Yazdi 2022b) such as interpretive structural modeling (ISM) and total interpretive structural modeling (TISM).

But the problem with classical DEMATEL is that it cannot handle vagueness in human decision-making (Lahane and Kant 2021b). In this regard, IFS DEMATEL and Pythagorean fuzzy set DEMATEL came into the picture to deal with vagueness in decision-making. This study uses Pythagorean fuzzy DEMATEL, which has an added advantage in dealing with imprecision over IFS DEMATEL.

Thus, in this study, the Pythagorean fuzzy set was used along with the DEMATEL approach to analyze the drivers of digital technologies to achieve sustainable production and consumption in a net-zero economy. Recently, many researchers have used Pythagorean fuzzy DEMATEL, as mentioned in Table 6.

The steps involved in the PF-DEMATEL approach are as follows:

-

Step 1: Developing a direct relation matrix

It is the first step in the PF-DEMATEL approach, where data is collected from experts and the raw data is presented in the form of a relationship matrix. The raw data collected from the experts was then converted into a Pythagorean fuzzy set (\({\mu }_{ij}, {\nu }_{ij}\)). The input relation matrix in the form of a Pythagorean fuzzy set is presented in Eq. 1 (Shafiee et al. 2022).

Further, the relationship matrix received from each expert was then aggregated together to make a single direct relationship matrix. A direct relationship matrix was formed by using Eq. 2 (Shafiee et al. 2022).

where \({a}_{ij}\) indicated the elements of aggregated direct relationship matrix, m represents the number of experts considered in the study, and \({\mu }_{ij}, {\nu }_{ij}\) is the rating in the form of a Pythagorean fuzzy set that indicates the influence of driver i on j by expert k.

-

Step 2: Conversion of the Pythagorean fuzzy average matrix into crisp number average direct relation matrix

Conversion of Pythagorean fuzzy set into crisp numbers was done using Eq. 3 and the average direct matrix in crisp numbers is presented in Eq. 4 (Lahane and Kant 2021b).

-

Step 3: Development of normalized relation matrix

Once we prepare the average crisp direct relation matrix, the next step is to develop a normalized relation matrix. The normalized relation matrix is formulated using Eq. 5 and is presented in Eq. 6 (Majumdar et al. 2022).

-

Step 4: Formulate the total relationship matrix (T)

The total relationship matrix is calculated by using Eq. 7.

where I is a unit matrix.

-

Step 5: Categorization of drivers into the cause-and-effect group

To categorize drivers into the cause-and-effect group, a total relation matrix was used. Each row and column of the total relation matrix are summed up and are represented by using the letters “R” and “C.” Further, (R + C) and (R − C) were calculated and are presented in Table 7. (R + C) shows the prominent score of a driver, i.e., the importance of a driver based on its dependence on others. (R − C) score shows the driver’s influence on the system. The positive value of (R − C) is categorized as cause group drivers whereas the negative value of (R − C) is categorized as effect group drivers.

Analysis and discussion

The above-described methodology was adopted to analyze the drivers of digitalization to achieve sustainable production and a net-zero economy. Data were collected from ten industrial experts (one—general manager, two—Sr. managers, three—managers, three—shift in charge, and one—industrial engineer) in the form of linguistic terms as specified in Table 5. Further, the collected data was then converted to Pythagorean fuzzy numbers. The data from all experts were then aggregated and converted into a crisp number, which is presented in Appendix Table 9. In Appendix Table 10, a normalized relation matrix is developed and is presented. Further, the total relation matrix is calculated and is presented in Appendix Table 11. Then finally, the drivers are categorized into the cause-and-effect group and are presented in Table 7.

Cause group drivers

The main objective of this study is to identify the major drivers of digitalization to achieve a net-zero economy in a supply-chain loop. The research findings are illustrated in the sections below to answer the research questions proposed for our study. To answer the research questions, the identified cause drivers are in a sequence based on the influential score of R + C. The influential map of drivers of digitalization was created and is presented in Fig. 3. Out of 11 causal drivers, three major and three minor drivers are identified from the analysis. The major three causal drivers, in ascending order, are high degree of automation, enhancing flexibility in the manufacturing process, and real-time sensing capability. From the bottom, the lowest three causal drivers are a high degree of security, decentralization of tactical decision-making, and high-quality product. In a similar way, the (R − C) value is also calculated for the cause-effect drivers. High computing power, availability of financial resources, and remote monitoring are the major causal factors. According to the (R–C) evaluation, the minimal cause drivers are decentralization of tactical decision-making, a high degree of security, and enhancing the flexibility in the manufacturing process.

Effect group drivers

Three major and minor drivers have been identified out of nine effect drivers. Globalization, enhanced resilience of the system, and digital culture are the three major effect drivers. Cost reduction supports from top management and reduced energy consumption are the minimal effect drivers. It is always required to attract stakeholders by adopting the net-zero economy in the supply chain. Similarly, all effect drivers for (R − C) show minimal values. All these cause-effect drivers need specific attention from scientists, policymakers, and researchers to be handled perfectly. The role of industry is very crucial in this regard. Scientists work continuously toward this success. Recycling industry products is the major focus of net-zero CE. Industry and academic collaboration is required on a long-term basis for the development to receive governmental funding. New-age technologies like cloud-IoT, AI-ML, and augmented reality are required to achieve multidisciplinary research work. Subscription-based technologies should be explored before being purchased from the same academic institutions.

A comparative study of current study with other published article on drivers of NZE is presented in Table 8.

Implications

Theoretical implications

Nowadays, industries are growing up to a net-zero economy in supply chain management. Twenty drivers were taken for the study. Out of twenty drivers, nineteen were filtered to finally answer the research questions that were identified from the literature and the research gaps. Based on the opinion of the domain experts, the questionnaire was circulated to the respective industries. Twenty drivers were tested using the help of the PF-DEMATEL approach. There are a greater number of cause groups than effect groups. Customer awareness can be achieved through collaborative work with academia and industry. The study has some unique contributions in terms of drivers. It exclusively analyzes the drivers and identifies the cause-effect relationships among the drivers. The cause-effect digraph only represents the strong effect. This strategy’s implementation will surely help organizations tackle new challenges. In the past few years, some researchers have started using the concept of the net-zero economy. The study explains the evolution of CE by using previous data from various geographical locations and industries. Many industries are not prepared for the net-zero economy and there is enough scope for future research agendas. The study will give future research directions in the field of the net-zero economy.

Practical implications

The present study has the following implications:

-

The study suggests that emerging technologies like artificial intelligence (AI), blockchain, and the internet of things (IoT) can contribute significantly to achieving sustainable practices in a net-zero economy. Therefore, individuals and organizations should adopt these technologies to enhance their sustainability practices.

-

Collaboration between different stakeholders, like businesses, governments, and civil society, is essential in promoting sustainable practices. The study highlights the importance of collaboration in the development and deployment of emerging technologies. Thus, policymakers and organizations should increase collaboration to leverage the potential of these technologies.

-

The study emphasizes the need to create awareness among individuals and organizations about the potential of emerging technologies in promoting sustainability. Therefore, organizations should create awareness campaigns and training programs to educate their employees and stakeholders about the benefits of such technologies.

-

The study suggests that innovation is critical to driving sustainable practices. Therefore, policymakers should encourage innovation through research grants and tax incentives to promote the development of sustainable technologies.

-

The study suggests that setting targets is essential to achieving sustainable practices. Therefore, policymakers should set targets for reducing greenhouse gas emissions and promoting sustainable practices in different sectors, such as transportation, agriculture, and energy.

Conclusion

Now the current trend in the supply chain is the NZE. Based on this trend, the drivers are also changing from a linear economy to CE and now NZE. Hence, from the literature review, twenty drivers were identified. Then it is filtered into 19 drivers based on their relevance to the specific industry. The DEMATEL analysis identifies important causal factors as a high degree of automation, enhancing the flexibility in the manufacturing process, and real-time sensing. The major contributions of the study are two-fold. It analyzes the drivers for implementation in various industries. The study draws a cause-effect digraph among the drivers to identify the major causes and the effects there after. This study will undoubtedly aid industries in maintaining a net-zero economy.

Our study has enough future scope for further research. The analysis technique can be a common method for academicians and industry people to maintain a net-zero economy. Researchers can use survey methods to determine the exact situation, which will be useful for future research on this topic. Even if so, many studies are available in this area, but still net-zero economy in supply chain management is still a contemporary research agenda with a lot on offer for exploration in future. Novel frameworks can be developed out of this study.

Again, the study has certain limitations. The outcome of the study will be useful for developing countries like India, where NZE is a very important factor. That is why the results should not be based on developed countries, where the values may vary. The analysis of the drivers is mostly dependent on the experts from academia and industry during the data collection stage. The finalized drivers can be utilized for CE and other technological methods such as neural networks. These drivers can be tested in other geographical locations with various industries in the future.

Future research can focus on evaluating the impact of emerging technologies on sustainable practices in different industries, such as energy, transportation, and agriculture. Such studies can explore the role of technologies such as blockchain, artificial intelligence, and the internet of things in facilitating sustainable practices and achieving NZE. Future research can focus on the potential of emerging technologies to reduce carbon footprints in different sectors. Another area of research can examine the role of policy and regulatory frameworks in promoting the adoption of emerging technologies in the context of sustainable practices and NZE. Such studies can explore the impact of government policies and incentives on the adoption of sustainable technologies and practices, and identify gaps that need to be addressed.

Data availability

All the data has been specified in the manuscript.

References

Abdullah L, Goh P (2019) Decision making method based on Pythagorean fuzzy sets and its application to solid waste management. Complex Intell Syst 5:185–198. https://doi.org/10.1007/s40747-019-0100-9

Agrawal R, Wankhede VA, Kumar A et al (2022) Nexus of circular economy and sustainable business performance in the era of digitalization. Int J Product Perform Manag 71:748–774. https://doi.org/10.1108/IJPPM-12-2020-0676

Aheleroff S, Zhong RY, Xu X (2020) A digital twin reference for mass personalization in industry 4.0. Procedia CIRP 93:228–233. https://doi.org/10.1016/j.procir.2020.04.023

Ajwani-Ramchandani R, Figueira S, de Torres Oliveira R et al (2021) Towards a circular economy for packaging waste by using new technologies: the case of large multinationals in emerging economies. J Clean Prod 281:125139. https://doi.org/10.1016/j.jclepro.2020.125139

Antikainen M, Uusitalo T, Kivikytö-Reponen P (2018) Digitalisation as an enabler of circular economy. Procedia CIRP 73:45–49. https://doi.org/10.1016/j.procir.2018.04.027

Belhadi A, Kamble SS, Chiappetta Jabbour CJ et al (2022) A self-assessment tool for evaluating the integration of circular economy and industry 4.0 principles in closed-loop supply chains. Int J Prod Econ 245:108372. https://doi.org/10.1016/j.ijpe.2021.108372

Bilal M, Jianqiu Z, Akram U et al (2020) The role of motivational factors for determining attitude towards eWOM in social media context. Int J Enterp Inf Syst 16:73–91. https://doi.org/10.4018/IJEIS.2020040105

Bonsu NO (2020) Towards a circular and low-carbon economy: insights from the transitioning to electric vehicles and net zero economy. J Clean Prod 256:120659. https://doi.org/10.1016/j.jclepro.2020.120659

Borchard R, Zeiss R, Recker J (2022) Digitalization of waste management: insights from German private and public waste management firms. Waste Manag Res: the Journal for a Sustainable Circular Economy 40:775–792. https://doi.org/10.1177/0734242X211029173

Bressanelli G, Pigosso DCA, Saccani N, Perona M (2021) Enablers, levers and benefits of circular economy in the electrical and electronic equipment supply chain: a literature review. J Clean Prod 298:126819. https://doi.org/10.1016/j.jclepro.2021.126819

Brundtland GH, Mansour K (1987) Report of the world commission on environment and development: our common future. https://sustainabledevelopment.un.org/content/documents/5987our-common-future.pdf

Burmaoglu S, Ozdemir Gungor D, Kirbac A, Saritas O (2022) Future research avenues at the nexus of circular economy and digitalization. Int J Product Perform Manag. https://doi.org/10.1108/IJPPM-01-2021-0026

Calabrese A, Levialdi Ghiron N, Tiburzi L (2021) ‘Evolutions’ and ‘revolutions’ in manufacturers’ implementation of industry 4.0: a literature review, a multiple case study, and a conceptual framework. Prod Plan Control 32:213–227. https://doi.org/10.1080/09537287.2020.1719715

Cardinali PG, de Giovanni P (2022) Responsible digitalization through digital technologies and green practices. Corp Soc Responsib Environ Manag 29:984–995. https://doi.org/10.1002/csr.2249

Chang L, Zhang Q, Liu H (2022) Digital finance innovation in green manufacturing: a bibliometric approach. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-021-18016-x

Chauhan C, Sharma A, Singh A (2021) A SAP-LAP linkages framework for integrating industry 4.0 and circular economy. Benchmarking: an Int J 28:1638–1664. https://doi.org/10.1108/BIJ-10-2018-0310

Chauhan C, Parida V, Dhir A (2022) Linking circular economy and digitalisation technologies: a systematic literature review of past achievements and future promises. Technol Forecast Soc Change 177:121508. https://doi.org/10.1016/j.techfore.2022.121508

D’Amato D, Droste N, Allen B et al (2017) Green, circular, bio economy: a comparative analysis of sustainability avenues. J Clean Prod 168:716–734. https://doi.org/10.1016/j.jclepro.2017.09.053

Dantas TET, de-Souza ED, Destro IR et al (2021) How the combination of circular economy and industry 4.0 can contribute towards achieving the sustainable development goals. Sustain Prod Consum 26:213–227. https://doi.org/10.1016/j.spc.2020.10.005

Dubey R, Gunasekaran A, Childe SJ et al (2019) Can big data and predictive analytics improve social and environmental sustainability? Technol Forecast Soc Change 144:534–545. https://doi.org/10.1016/j.techfore.2017.06.020

Fatorachian H, Kazemi H (2021) Impact of industry 4.0 on supply chain performance. Prod Plan Control 32:63–81. https://doi.org/10.1080/09537287.2020.1712487

Fernando Y, Halili M, Tseng M-L et al (2022) Sustainable social supply chain practices and firm social performance: framework and empirical evidence. Sustain Prod Consum 32:160–172. https://doi.org/10.1016/j.spc.2022.04.020

García-Muiña F, Medina-Salgado MS, González-Sánchez R et al (2022) Social organizational life cycle assessment (SO-LCA) and organization 4.0: an easy-to-implement method. MethodsX 9:101692. https://doi.org/10.1016/j.mex.2022.101692

Geissdoerfer M, Savaget P, Bocken NMP, Hultink EJ (2017) The circular economy – a new sustainability paradigm? J Clean Prod 143:757–768. https://doi.org/10.1016/j.jclepro.2016.12.048

Ghisellini P, Cialani C, Ulgiati S (2016) A review on circular economy: the expected transition to a balanced interplay of environmental and economic systems. J Clean Prod 114:11–32. https://doi.org/10.1016/j.jclepro.2015.09.007

Ghobakhloo M (2020) Determinants of information and digital technology implementation for smart manufacturing. Int J Prod Res 58:2384–2405. https://doi.org/10.1080/00207543.2019.1630775

Giri BC, Molla MU, Biswas P (2022) Pythagorean fuzzy DEMATEL method for supplier selection in sustainable supply chain management. Expert Syst Appl 193:116396. https://doi.org/10.1016/j.eswa.2021.116396

Govindan K, Hasanagic M (2018) A systematic review on drivers, barriers, and practices towards circular economy: a supply chain perspective. Int J Prod Res 56:278–311. https://doi.org/10.1080/00207543.2017.1402141

Grover V, Tseng S-L, Pu W (2022) A theoretical perspective on organizational culture and digitalization. Inform Manag 59:103639. https://doi.org/10.1016/j.im.2022.103639

Ha LT, Huong TTL, Thanh TT (2022) Is digitalization a driver to enhance environmental performance? An empirical investigation of European countries. Sustain Prod Consum 32:230–247. https://doi.org/10.1016/j.spc.2022.04.002

Hecklau F, Galeitzke M, Flachs S, Kohl H (2016) Holistic approach for human resource management in industry 4.0. Procedia CIRP 54:1–6. https://doi.org/10.1016/j.procir.2016.05.102

Hong Nham NT, Ha LT (2022) Making the circular economy digital or the digital economy circular? Empirical evidence from the European region. Technol Soc 70:102023. https://doi.org/10.1016/j.techsoc.2022.102023

IEA (2020) International Energy Agency (IEA) on Net Zero by 2050; A roadmap for the global energy sector. https://www.iea.org/reports/net-zero-by-2050

Ingemarsdotter E, Jamsin E, Balkenende R (2020) Opportunities and challenges in IoT-enabled circular business model implementation – a case study. Resour Conserv Recycl 162:105047. https://doi.org/10.1016/j.resconrec.2020.105047

Ivanov D, Rozhkov M (2020) Coordination of production and ordering policies under capacity disruption and product write-off risk: an analytical study with real-data based simulations of a fast moving consumer goods company. Ann Oper Res 291:387–407. https://doi.org/10.1007/s10479-017-2643-8

Jarrett H (2013) Environmental quality in a growing economy. RFF Press. https://doi.org/10.2307/2229494

Jenkins JD, Mayfield EN, Larson ED et al (2021) Mission net-zero America: the nation-building path to a prosperous, net-zero emissions economy. Joule 5:2755–2761. https://doi.org/10.1016/j.joule.2021.10.016

Kadar T, Kadar M (2020) Sustainability is not enough: towards AI supported regenerative design. In: 2020 IEEE international conference on engineering, technology and innovation (ICE/ITMC). IEEE, pp. 1–6. https://doi.org/10.1109/ICE/ITMC49519.2020.9198554

Kagermann H (2015) Change through digitization—value creation in the age of industry 4.0. Management of permanent change. Springer Fachmedien Wiesbaden, Wiesbaden, pp 23–45

Kamble SS, Gunasekaran A, Gawankar SA (2018a) Sustainable industry 4.0 framework: a systematic literature review identifying the current trends and future perspectives. Process Saf Environ Prot 117:408–425. https://doi.org/10.1016/j.psep.2018.05.009

Kamble SS, Gunasekaran A, Sharma R (2018b) Analysis of the driving and dependence power of barriers to adopt industry 4.0 in Indian manufacturing industry. Comput Ind 101:107–119. https://doi.org/10.1016/j.compind.2018.06.004

Karekla M, Pollalis Y, Angelopoulos M (2021) Key drivers of digital transformation in greek businesses: strategy vs. technology. Cent Eur Manag J 29:33–62. https://doi.org/10.7206/cemj.2658-0845.45

Kaur J, Kumar S, Narkhede BE et al (2022) Barriers to blockchain adoption for supply chain finance: the case of Indian SMEs. Electron Commer Res. https://doi.org/10.1007/s10660-022-09566-4

Khan SAR, Zia-ul-haq HM, Umar M, Yu Z (2021) Digital technology and circular economy practices: an strategy to improve organizational performance. Bus Strat Dev 4:482–490. https://doi.org/10.1002/bsd2.176

Kılkış B, Kılkış Ş (2018) Hydrogen economy model for nearly net-zero cities with exergy rationale and energy-water nexus. Energies (Basel) 11:1226. https://doi.org/10.3390/en11051226

Korhonen J, Honkasalo A, Seppälä J (2018) Circular economy: the concept and its limitations. Ecol Econ 143:37–46. https://doi.org/10.1016/j.ecolecon.2017.06.041

Kovacikova M, Janoskova P, Kovacikova K (2021) The impact of emissions on the environment within the digital economy. Transp Res Procedia 55:1090–1097. https://doi.org/10.1016/j.trpro.2021.07.080

Kristoffersen E, Blomsma F, Mikalef P, Li J (2020) The smart circular economy: a digital-enabled circular strategies framework for manufacturing companies. J Bus Res 120:241–261. https://doi.org/10.1016/j.jbusres.2020.07.044

Ku AY, de Souza A, McRobie J et al (2021) Zero-emission public transit could be a catalyst for decarbonization of the transportation and power sectors. Clean Energy 5:492–504. https://doi.org/10.1093/ce/zkab029

Kumar S, Raut RD, Nayal K et al (2021) To identify industry 4.0 and circular economy adoption barriers in the agriculture supply chain by using ISM-ANP. J Clean Prod 293:126023. https://doi.org/10.1016/j.jclepro.2021.126023

Kurniawan TA, Maiurova A, Kustikova M et al (2022) Accelerating sustainability transition in St. Petersburg (Russia) through digitalization-based circular economy in waste recycling industry: a strategy to promote carbon neutrality in era of industry 4.0. J Clean Prod 363:132452. https://doi.org/10.1016/j.jclepro.2022.132452

Lahane S, Kant R (2021a) Evaluation and ranking of solutions to mitigate circular supply chain risks. Sustain Prod Consum 27:753–773. https://doi.org/10.1016/j.spc.2021.01.034

Lahane S, Kant R (2021b) Evaluating the circular supply chain implementation barriers using Pythagorean fuzzy AHP-DEMATEL approach. Clean Logist Supply Chain 2:100014. https://doi.org/10.1016/j.clscn.2021.100014

Li H, Yazdi M (2022a) Dynamic decision-making trial and evaluation laboratory (DEMATEL): improving safety management system. pp 1–14

Li H, Yazdi M (2022b) What are the critical well-drilling blowouts barriers? A progressive DEMATEL-game theory. pp 29–46. https://doi.org/10.1007/978-3-031-07430-1_3

Majumdar A, Ali SM, Agrawal R, Srivastava S (2022) A triple helix framework for strategy development in circular textile and clothing supply chain: an Indian perspective. J Clean Prod 367:132954. https://doi.org/10.1016/j.jclepro.2022.132954

Manninen K, Koskela S, Antikainen R et al (2018) Do circular economy business models capture intended environmental value propositions? J Clean Prod 171:413–422. https://doi.org/10.1016/j.jclepro.2017.10.003

Marques M, Agostinho C, Zacharewicz G, Jardim-Gonçalves R (2017) Decentralized decision support for intelligent manufacturing in industry 4.0. J Ambient Intell Smart Environ 9:299–313. https://doi.org/10.3233/AIS-170436

Mishra R, Singh R, Govindan K (2022) Net-zero economy research in the field of supply chain management: a systematic literature review and future research agenda. Int J Logist Manag. https://doi.org/10.1108/IJLM-01-2022-0016

Murray A, Skene K, Haynes K (2017) The circular economy: an interdisciplinary exploration of the concept and application in a global context. J Bus Ethics 140:369–380. https://doi.org/10.1007/s10551-015-2693-2

Nandi S, Sarkis J, Hervani AA, Helms MM (2021) Redesigning supply chains using blockchain-enabled circular economy and COVID-19 experiences. Sustain Prod Consum 27:10–22. https://doi.org/10.1016/j.spc.2020.10.019

Nobre GC, Tavares E (2020) Assessing the role of big data and the internet of things on the transition to circular economy: part II : an extension of the ReSOLVE framework proposal through a literature review. Johnson Matthey Technol Rev 64:32–41. https://doi.org/10.1595/205651319X15650189172931

Nowakowski P, Pamuła T (2020) Application of deep learning object classifier to improve e-waste collection planning. Waste Manag 109:1–9. https://doi.org/10.1016/j.wasman.2020.04.041

Okorie O, Russell J, Cherrington R et al (2023) Digital transformation and the circular economy: creating a competitive advantage from the transition towards net zero manufacturing. Resour Conserv Recycl 189:106756. https://doi.org/10.1016/j.resconrec.2022.106756

Pan W, Pan M (2021) Drivers, barriers and strategies for zero carbon buildings in high-rise high-density cities. Energy Build 242:110970. https://doi.org/10.1016/j.enbuild.2021.110970

Patalas-Maliszewska J, Skrzeszewska M (2018) An evaluation of the effectiveness of applying the MES in a maintenance department – a case study. Found Manag 10:257–270. https://doi.org/10.2478/fman-2018-0020

Pearce DW, Turner RK (1989) Economics of natural resources and the environment. David W. Pearce and Kerry Turner R (eds). United Kingdom: Johns Hopkins University Press

Peiró LT, Baiguera F, Maci A et al (2021) Digitalization as an enabler of the circular economy of electronics. Procedia Manuf 54:58–63. https://doi.org/10.1016/j.promfg.2021.07.010

Porter ME, Heppelmann JE (2014) How smart, connected products are transforming competition. Harv Bus Rev 92:64–88

Rachinger M, Rauter R, Müller C et al (2019) Digitalization and its influence on business model innovation. J Manuf Technol Manag 30:1143–1160. https://doi.org/10.1108/JMTM-01-2018-0020

Raimo N, de Turi I, Albergo F, Vitolla F (2022) The drivers of the digital transformation in the healthcare industry: an empirical analysis in Italian hospitals. Technovation 102558. https://doi.org/10.1016/j.technovation.2022.102558

Rejeb A, Suhaiza Z, Rejeb K et al (2022) The internet of things and the circular economy: a systematic literature review and research agenda. J Clean Prod 350:131439. https://doi.org/10.1016/j.jclepro.2022.131439

Rüßmann M, Lorenz M, Gerbert P, Waldner M, Justus J, Engel P, Harnisch M (2015) Industry 4.0: the future of productivity and growth in manufacturing industries. Boston consulting group 9(1):54–89

Rymaszewska A, Helo P, Gunasekaran A (2017) IoT powered servitization of manufacturing – an exploratory case study. Int J Prod Econ 192:92–105. https://doi.org/10.1016/j.ijpe.2017.02.016

Sachs J, Kroll C, Lafortune G Fuller, G, Woelm F (2021) The decade of action for the sustainable development goals: sustainable development report 2021. Published online at sdgindex.org, Cambridge, UK Retrieved from: https://unstats.un.org/sdgs/report/2020/. Accessed 5 Dec 2022

Sakao T, Funk P, Matschewsky J et al (2021) AI-LCE: adaptive and intelligent life cycle engineering by applying digitalization and AI methods – an emerging paradigm shift in life cycle engineering. Procedia CIRP 98:571–576. https://doi.org/10.1016/j.procir.2021.01.153

Schneider M (2018) Digitalization of production, human capital, and organizational capital. pp. 39–52. https://doi.org/10.1007/978-3-319-63257-5_4

Sehnem S, Oliveira GP (2017) Analysis of the supplier and agribusiness relationship. J Clean Prod 168:1335–1347. https://doi.org/10.1016/j.jclepro.2017.08.240

Shafiee M, Zare-Mehrjerdi Y, Govindan K, Dastgoshade S (2022) A causality analysis of risks to perishable product supply chain networks during the COVID-19 outbreak era: an extended DEMATEL method under Pythagorean fuzzy environment. Transp Res E Logist Transp Rev 163:102759. https://doi.org/10.1016/j.tre.2022.102759

Shahsavari A, Akbari M (2018) Potential of solar energy in developing countries for reducing energy-related emissions. Renew Sustain Energy Rev 90:275–291. https://doi.org/10.1016/j.rser.2018.03.065

Shevchenko A, Lévesque M, Pagell M (2016) Why firms delay reaching true sustainability. J Manag Stud 53:911–935. https://doi.org/10.1111/joms.12199

Singh R, Gehlot A, Vaseem Akram S et al (2021) Forest 4.0: digitalization of forest using the internet of things (IoT). J King Saud Univ-Comp Inform Sci. https://doi.org/10.1016/j.jksuci.2021.02.009

Singh J, Pandey KK, Kumar A et al (2022) Drivers, barriers and practices of net zero economy: an exploratory knowledge based supply chain multi-stakeholder perspective framework. Oper Manag Res. https://doi.org/10.1007/s12063-022-00255-x

Sivri Ç, Gül S, Aksu OR (2022) A novel Pythagorean fuzzy extension of DEMATEL and its usage on overcoat selection attributes for Antarctic clothing. Int J Inf Technol Decis Mak 21:821–850. https://doi.org/10.1142/S021962202250002X

Sofuoğlu E, Kirikkaleli D (2022) Towards achieving net zero emission targets and sustainable development goals, can long-term material footprint strategies be a useful tool? Environ Sci Pollut Res. https://doi.org/10.1007/s11356-022-24078-2

Sousa-Zomer TT, Magalhães L, Zancul E et al (2018) Cleaner production as an antecedent for circular economy paradigm shift at the micro-level: evidence from a home appliance manufacturer. J Clean Prod 185:740–748. https://doi.org/10.1016/j.jclepro.2018.03.006

Sovacool BK (2016) Cobenefits and trade-offs of green and clean energy: evidence from the academic literature and Asian case studies. SSRN Electron J. https://doi.org/10.2139/ssrn.2894768

Stentoft J, Adsbøll Wickstrøm K, Philipsen K, Haug A (2021) Drivers and barriers for industry 4.0 readiness and practice: empirical evidence from small and medium-sized manufacturers. Prod Plan Control 32:811–828. https://doi.org/10.1080/09537287.2020.1768318

Stern N, Valero A (2021) Innovation, growth and the transition to net-zero emissions. Res Policy 50:104293. https://doi.org/10.1016/j.respol.2021.104293

Tiwari R (2021) Digital transformation as enabler of affordable green excellence: an investigation of frugal innovations in the wind energy sector. pp. 247–277. https://doi.org/10.1007/978-3-030-67119-8_12

Tseng M-L, Tan RR, Chiu ASF et al (2018) Circular economy meets industry 4.0: can big data drive industrial symbiosis? Resour Conserv Recycl 131:146–147. https://doi.org/10.1016/j.resconrec.2017.12.028

Tumilar AS, Milani D, Cohn Z et al (2020) A modelling framework for the conceptual design of low-emission eco-industrial parks in the circular economy: a case for algae-centered business consortia. Water (basel) 13:69. https://doi.org/10.3390/w13010069

Tura N, Hanski J, Ahola T et al (2019) Unlocking circular business: a framework of barriers and drivers. J Clean Prod 212:90–98. https://doi.org/10.1016/j.jclepro.2018.11.202

van Schalkwyk RF, Reuter MA, Gutzmer J, Stelter M (2018) Challenges of digitalizing the circular economy: assessment of the state-of-the-art of metallurgical carrier metal platform for lead and its associated technology elements. J Clean Prod 186:585–601. https://doi.org/10.1016/j.jclepro.2018.03.111

Walk P, Stognief N (2022) From coal phase-out to net zero: driving factors of UK climate policy. Environ Sci Policy 138:76–84. https://doi.org/10.1016/j.envsci.2022.09.019

Wankhede VA, Vinodh S (2022) State of the art review on industry 4.0 in manufacturing with the focus on automotive sector. Int J Lean Six Sigma 13:692–732. https://doi.org/10.1108/IJLSS-05-2021-0101

Wehner J, Taghavi Nejad Deilami N, Altuntas Vural C, Halldórsson Á (2021) Logistics service providers’ energy efficiency initiatives for environmental sustainability. Int J Logist Manag 33:1–26. https://doi.org/10.1108/IJLM-10-2019-0270

Wilson M, Paschen J, Pitt L (2022) The circular economy meets artificial intelligence (AI): understanding the opportunities of AI for reverse logistics. Manag Environ Qual: an Int J 33:9–25. https://doi.org/10.1108/MEQ-10-2020-0222

Xie Y, Zhou Y, Peng Y et al (2021) An extended Pythagorean fuzzy approach to group decision-making with incomplete preferences for analyzing balanced scorecard-based renewable energy investments. IEEE Access 9:43020–43035. https://doi.org/10.1109/ACCESS.2021.3065294

Yan X, Deng Y, Peng L, Jiang Z (2022) Study on the impact of digital economy development on carbon emission intensity of urban agglomerations and its mechanism. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-022-24557-6

Yang M, Smart P, Kumar M et al (2018) Product-service systems business models for circular supply chains. Prod Plan Control 29:498–508. https://doi.org/10.1080/09537287.2018.1449247

Yang M, Fu M, Zhang Z (2021) The adoption of digital technologies in supply chains: drivers, process and impact. Technol Forecast Soc Change 169:120795. https://doi.org/10.1016/j.techfore.2021.120795

Yazdi M, Nedjati A, Zarei E, Abbassi R (2020) A novel extension of DEMATEL approach for probabilistic safety analysis in process systems. Saf Sci 121:119–136. https://doi.org/10.1016/j.ssci.2019.09.006

Yuan Z, Bi J, Moriguichi Y (2008) The circular economy: a new development strategy in China. J Ind Ecol 10:4–8. https://doi.org/10.1162/108819806775545321

Yüksel S, Dinçer H (2022) Identifying the strategic priorities of nuclear energy investments using hesitant 2-tuple interval-valued Pythagorean fuzzy DEMATEL. Prog Nucl Energy 145:104103. https://doi.org/10.1016/j.pnucene.2021.104103

Zeng H, Chen X, Xiao X, Zhou Z (2017) Institutional pressures, sustainable supply chain management, and circular economy capability: empirical evidence from Chinese eco-industrial park firms. J Clean Prod 155:54–65. https://doi.org/10.1016/j.jclepro.2016.10.093

Zhang J, Lyu Y, Li Y, Geng Y (2022) Digital economy: an innovation driving factor for low-carbon development. Environ Impact Assess Rev 96:106821. https://doi.org/10.1016/j.eiar.2022.106821

Author information

Authors and Affiliations

Contributions

Rohit Agrawal: conceptualization, data curation, methodology, and writing—original draft. Pragati Priyadarshinee: methodology, data curation, and visualization. Anil Kumar: visualization, supervision, and editing. Sunil Luthra: writing—review and editing. Jose Arturo Garza-Reyes: review and editing. Sneha Kadyan: drafting the paper and editing.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

All authors have followed the ethics in the research and gave consent to participate in the research.

Consent for publication

All authors give consent for publication.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Ilhan Ozturk

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Agrawal, R., Priyadarshinee, P., Kumar, A. et al. Are emerging technologies unlocking the potential of sustainable practices in the context of a net-zero economy? An analysis of driving forces. Environ Sci Pollut Res (2023). https://doi.org/10.1007/s11356-023-26434-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11356-023-26434-2