Abstract

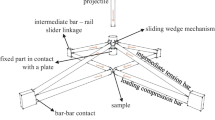

An indirect tensile testing method is proposed to measure the full dynamic tensile stress-strain curve of low strength brittle solids. In this method, the flattened-Brazilian disc (FBD) sample is loaded by modified split Hopkinson pressure bars (SHPB) system. Low amplitude dynamic forces were measured with a pair of piezoelectric force transducers embedded in the incident bar and the transmitted bar. The evolution of tensile stress at the center of the disc sample was determined through finite element analyses using the measured stress in SHPB as inputs. In a traditional Brazilian test, a strain gauge is mounted at the center of the specimen to measure the tensile strain, which is difficult to apply for low strength brittle materials. Thus, two types of non-contact methods, the Digital Image Correlation (DIC) technique and the Laser Gap Gauge (LGG), were used to measure the strain. The DIC method was used to monitor the displacement and the strain map of the specimen during the test, from which the strain at the center of the specimen can be obtained. The accuracy of the DIC results was assessed, and the displacement and strain uncertainties of our system were 0.003 mm and 0.003, respectively. LGG was used to monitor the expansion of the disc perpendicular to the loading axis, from which the average tensile strain is deduced. The numerical simulation revealed that the tensile strain at the center of the specimen is proportional to the average tensile strain and that the ratio is not sensitive to the material elastic parameters. The strain measured through LGG was compared with that measured by the DIC method using photos captured with a synchronized high-speed camera. The result of the LGG method was 20 % smaller than that of the DIC process. However, the latter was limited by the number of frames of the high-speed camera. The feasibility of this methodology was demonstrated using a polymer-bonded explosive (PBX).

Similar content being viewed by others

References

Berenbaum R, Brodie I (1959) Measurement of the tensile strength of brittle materials. Br J Appl Phys 10:281–286

Awaji H, Sato S (1979) Diametral compressive testing method. J Eng Mater-T ASME 101:139–147

Wang QZ, Jia XM, Kou SQ et al (2004) The flattened Brazilian disc specimen used for testing elastic modulus, tensile strength and fracture toughness of brittle rocks: analytical and numerical results. Int J Rock Mech Min 41:245–253

Kolsky H (1949) An investigation of the mechanical properties of materials at very high rates of loading. Proc R Soc Lond Ser Math Phys Sci B62:676–700

Chen W, Lu F, Zhou B (2000) A quartz-crystal-embedded split Hopkinson pressure bar for soft materials. Exp Mech 40:1–6

Sutton MA, Bruck HA, McNeill SR (1989) Determination of deformations using digital correlation with the Newton-Raphson method for partial differential correlations. Exp Mech 29:261–267

Gilat A, Schmidt TE, Walker AL (2009) Full field strain measurement in compression and tensile split Hopkinson bar experiments. Exp Mech 49:291–302

Hild F, Roux S (2006) Digital image correlation: from displacement measurement to identification of elastic properties - a review. Strain 42:69–80

Hung P-C, Voloshin AS (2003) In-plane strain measurement by digital image correlation. J Braz Soc Mech Sci Eng 25:215–221

Rae PJ, Palmer S, Goldrein HT et al (2004) White-light digital image cross-correlation (DICC) analysis of the deformation of composite materials with random microstructure. Opt Lasers Eng 41:635–648

Grantham SG, Siviour CR, Proud WG et al (2004) High-strain rate Brazilian testing of an explosive simulant using speckle metrology. Meas Sci Technol 15:1867–1870

Chen R, Huang S, Xia K et al (2009) A modified Kolsky bar system for testing ultrasoft materials under intermediate strain rates. Rev Sci Instrum 80:076108

Wang QZ, Li W, Xie HP (2009) Dynamic split tensile test of flattened Brazilian disc of rock with SHPB setup. Mech Mater 41:252–260

Frew DJ, Forrestal MJ, Chen W (2002) Pulse shaping techniques for testing brittle materials with a split Hopkinson pressure bar. Exp Mech 42:93–106

Chen R, Xia K, Dai F et al (2009) Determination of dynamic fracture parameters using a semi-circular bend technique in split Hopkinson pressure bar testing. Eng Fract Mech 76:1268–1276

Acknowledgment

This work is supported by the Natural Science Foundation of China (NSFC) through Grant Nos. 11132012, 11202232 & 11172328 and by the Foundation of NUDT (No. JC-11-02-17). F. Dai acknowledges the support of the Sichuan Youth Science & Technology Foundation (No. 2012JQ0031).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, R., Dai, F., Qin, J. et al. Flattened Brazilian Disc Method for Determining the Dynamic Tensile Stress-Strain Curve of Low Strength Brittle Solids. Exp Mech 53, 1153–1159 (2013). https://doi.org/10.1007/s11340-013-9733-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-013-9733-6