Abstract

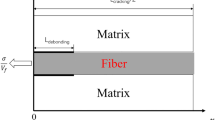

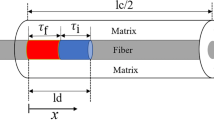

The mechanical response of SiC-fiber reinforced barium osumilite ceramic matrix composites tested in tension with unloading/reloading cycles was very recently reported to exhibit self-assembling common intersection points (CIP) of unloading/reloading loops in the tensile domain which relate exactly to the thermal residual stress state of reinforcing fibers in a matrix of a lower coefficient of thermal expansion (Dassios et al. Compos A: Appl Sci Manuf 44:105–113, 2013). Knowledge of the experimentally-exact residual stress state enables, herein, examination of the validity of the conventional compliance-based methodology for indirectly calculating residual stresses from projected/extrapolated CIPs. The efficiency of two prominent residual stress prediction models is also tested across the experimentally-established value of thermal residual stress (TRS). The significance of the CIP as the TRS-free origin of the stress-strain curve is discussed in view of the importance in calculating accurate material property values from mechanical testing data of materials under residual stress.

Similar content being viewed by others

References

Dassios KG, Aggelis DG, Kordatos EZ, Matikas TE (2013) Cyclic loading of a SiC-fiber reinforced ceramic matrix composite reveals damage mechanisms and thermal residual stress state. Compos A: Appl Sci Manuf 44:105–113

Selsing J (1961) Internal stresses in ceramics. J Am Ceram Soc 44:419

Young RJ, Yang X (1996) Interfacial failure in ceramic fibre/glass composites. Compos A: Appl Sci Manuf 27:737–741

Faber KT (1997) Ceramic composite interfaces: properties and design. Annu Rev Mater Sci 27:499–524

Cook RF, Lawn BR, Dabbs TP, Chantikul P (1981) Effect of machining damage on the strength of a glass-ceramic. J Am Ceram Soc 64:C121–C122

Kotoul M, Pokluda J, Sandera P, Dlouhy I, Chlup Z, Boccaccini AR (2008) Toughening effects quantification in glass matrix composite reinforced by alumina platelets. Acta Mater 56:2908–2918

Serbena FC, Zanotto ED (2012) Internal residual stresses in glass-ceramics: a review. J Non-Cryst Solids 358:975–984

Withers PJ, Bhadeshia HKDH (2001) Overview—Residual stress part 1—Measurement techniques. Mater Sci Technol Ser 17:355–365

Yang X, Young RJ (1994) Model ceramic fiber-reinforced glass composites—residual thermal-stresses. Composites 25:488–493

Dassios KG, Galiotis C (2006) Direct measurement of fiber bridging in notched glass-ceramic-matrix composites. J Mater Res 21:1150–1160

Pezzotti G, Sbaizero O, Sergo V, Muraki N, Maruyama K, Nishida T (1998) In situ measurements of frictional bridging stresses in alumina using fluorescence spectroscopy. J Am Ceram Soc 81:187–192

Guo S, Todd RI (2010) Cr3+ microspectroscopy measurements and modelling of local variations in surface grinding stresses in polycrystalline alumina. J Eur Ceram Soc 30:2533–2545

Peitl O, Serbena FC, Mastelaro VR, Zanotto ED (2010) Internal residual stress measurements in a bioactive glass-ceramic using Vickers indentation. J Am Ceram Soc 93:2359–2368

Camus G, Guillaumat L, Baste S (1996) Development of damage in a 2D woven C/SiC composite under mechanical loading.1. Mechanical characterization. Compos Sci Technol 56:1363–1372

Steen M (1998) Tensile mastercurve of ceramic matrix composites: significance and implications for modelling. Mat Sci Eng A Struct 250:241–248

Mei H (2008) Measurement and calculation of thermal residual stress in fiber reinforced ceramic matrix composites. Compos Sci Technol 68:3285–3292

Mei H, Cheng LF (2009) Comparison of the mechanical hysteresis of carbon/ceramic-matrix composites with different fiber preforms. Carbon 47:1034–1042

Morscher GN, Singh M, Kiser JD, Freedman M, Bhatt R (2007) Modeling stress-dependent matrix cracking and stress–strain behavior in 2D woven SiC fiber reinforced CVISiC composites. Compos Sci Technol 67:1009–1017

Cooper RF, Chyung K (1987) Structure and chemistry of fiber matrix interfaces in silicon-carbide fiber-reinforced glass ceramic composites—an Electron-Microscopy Study. J Mater Sci 22:3148–3160

Benson PM, Spear KE, Pantano GC (1988) Interfacial characterisation of glass matrix/Nicalon SiC fiber composites: a thermodynamic approach. Ceram Eng Sci Proc 9:663–670

Wang M, Laird C (1996) Characterization of microstructure and tensile behavior of a cross-woven C-SiC composite. Acta Mater 44:1371–1387

Wang MD, Laird C (1997) Tension-tension fatigue of a cross-woven C/SiC composite. Mat Sci Eng a-Struct 230:171–182

Cady C, Evans AG, Perry KE (1995) Stress redistribution around mechanical attachments in ceramic-matrix composites. Composites 26:683–690

Mei H, Cheng LF (2011) Stress-dependence and time-dependence of the post-fatigue tensile behavior of carbon fiber reinforced SiC matrix composites. Compos Sci Technol 71:1404–1409

Widjaja S (2001) Determination of creep-induced residual stress in fiber-reinforced glass-ceramic matrix composites by X-ray diffraction. Mater Charact 47:47–54

Jais US, Lee WE, James PF (1999) Crystallization of barium osumilite glass. J Am Ceram Soc 82:3200–3208

Hsueh CH, Becher PF (1988) Thermal-expansion coefficients of unidirectional fiber-reinforced ceramics. J Am Ceram Soc 71:C438–C441

Vanwijgenhoven E, Wevers ML, van der Biest O (1999) Influence of the laminate lay-up on the fatigue behaviour of SiC-fibre/BMAS-matrix composites. Compos A: Appl Sci Manuf 30:623–635

Johnsonwalls D, Evans AG, Marshall DB, James MR (1986) Residual-stresses in machined ceramic surfaces. J Am Ceram Soc 69:44–47

Boyce BL, Chen X, Peters JO, Hutchinson JW, Ritchie RO (2003) Mechanical relaxation of localized residual stresses associated with foreign object damage. Mater Sci Eng A Struct 349:48–58

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dassios, K.G., Matikas, T.E. Residual Stress-Related Common Intersection Points in the Mechanical Behavior of Ceramic Matrix Composites Undergoing Cyclic Loading. Exp Mech 53, 1033–1038 (2013). https://doi.org/10.1007/s11340-012-9709-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-012-9709-y