Abstract

Performance of hydropower plant is severely affected by the presence of sand particles in river water. Degree of degradation significantly depends on the level of operating parameters (velocity, impingement angle, concentration, particle size and shape), which is further related to erosion mechanism. In this investigation, the effect of some of these operating parameters on erosion mechanism of generally used hydroturbine steel, CA6NM (13Cr4Ni), is reported. Morphology and variation in the martensite and austenite phases of the eroded surfaces were investigated using SEM and XRD. It was observed that velocity and impingement angle affect the erosion mechanism of CA6NM steel. Erosion mechanism was also significantly affected by the radial distance from the impact zone. Primary mechanism responsible for the removal of material at normal impingement angle was the formation and removal of platelets. At acute impingement angle, ploughing was observed to be one of the prime mechanisms responsible for the loss of the material. Other than these two well-known erosion mechanisms, the presence of another two erosion mechanisms was also observed. Models have been proposed for these unfamiliar erosion mechanisms. Interaction amongst different operating parameters was studied using line and contour plots. It was observed that the interaction between velocity and concentration was most significant. Using the experimental results, a statistical model based on regression approach was developed. Validity of this statistical model was checked using the experimental results from the literature and present study.

Similar content being viewed by others

References

Humphrey, J.A.C.: Fundamentals of fluid motion in erosion by solid particle impact. Int. J. Heat and Fluid Flow 11(3), 170–195 (1990)

Mann, B.S., Arya, V.: Abrasive and erosive wear characteristics of plasma nitriding and HVOF coatings: their application in hydro turbines. Wear 249(5–6), 354–360 (2001)

Bajracharya, T.R., Acharya, B., Joshi, C.B., Saini, R.P., Dahlhaug, O.G.: Sand erosion of Pelton turbine nozzles and buckets: A case study of chilime hydropower plant. Wear 264(3–4), 177–184 (2008)

Iwabuchi, Y., Sawada, S.: Metallurgical characteristics of a large hydraulic runner casting of type 13Cr-Ni stainless Steel. In: 1982, pp. 332–354. ASTM

Antunes, F.F., Cornman, R.E., Hartkopf, R.J.: Centrifugal pumps for desalination. Desalination 38, 109–122 (1981)

Jeske, H.O.: Charge-gas compressors in coal gasification and olefin plants—25 years of experience with a vital plant component. Chem. Eng. Process. 18(2), 113–122 (1984)

Kim, J.W., Kim, Y.S., Park, C.Y.: Failure analysis of cracking at volute tongues of feedwater pump casings. Eng. Fail. Anal. 9(1), 17–30 (2002)

Chauhan, A.K., Goel, D.B., Prakash, S.: Erosion behaviour of hydro turbine steels. Bull. Mater. Sci. 31(2), 115–120 (2008)

Grewal, H.S., Bhandari, S., Singh, H.: Parametric study of slurry-erosion of hydroturbine steels with and without detonation gun spray coatings using taguchi technique. Metall. Mater. Trans. A 43(9), 3387–3401 (2012)

Manisekaran, T., Kamaraj, M., Sharrif, S.M., Joshi, S.V.: Slurry erosion studies on surface modified 13Cr-4Ni steels: Effect of angle of impingement and particle size. J. Mater. Eng. Perform. 16(5), 567–572 (2007)

Shivamurthy, R.C., Kamaraj, M., Nagarajan, R., Shariff, S.M., Padmanabham, G.: Influence of microstructure on slurry erosive wear characteristics of laser surface alloyed 13Cr–4Ni steel. Wear 267(1–4), 204–212 (2009)

Shivamurthy, R.C., Kamaraj, M., Nagarajan, R., Shariff, S.M., Padmanabham, G.: Slurry erosion characteristics and erosive wear mechanisms of Co-based and Ni-based coatings formed by laser surface alloying. Metall. Mater. Trans. A 41(2), 470–486 (2009)

Sugiyama, K., Nakahama, S., Hattori, S., Nakano, K.: Slurry wear and cavitation erosion of thermal-sprayed cermets. Wear 258(5–6), 768–775 (2005)

Romo, S.A., Santa, J.F., Giraldo, J.E., Toro, A.: Cavitation and high-velocity slurry erosion resistance of welded Stellite 6 alloy. Tribol. Int. 47, 16–24 (2012)

Sugiyama, K., Harada, K., Hattori, S.: Influence of impact angle of solid particles on erosion by slurry jet. Wear 265(5–6), 713–720 (2008)

Sugiyama, K., Harada, K., Hattori, S.: Prediction of the volume loss by using slurry jet test on SCS6. J. Solid Mech. Mater. Eng. 2(7), 955–966 (2008)

Mann, B.S.: High-energy particle impact wear resistance of hard coatings and their application in hydroturbines. Wear 237, 140–146 (2000)

Chattopadhyay, R.: High silt wear of hydroturbine runners. Wear 162, 1040–1044 (1993)

Santa, J., Baena, J., Toro, A.: Slurry erosion of thermal spray coatings and stainless steels for hydraulic machinery. Wear 263(1–6), 258–264 (2007)

Santa, J.F., Espitia, L.A., Blanco, J.A., Romo, S.A., Toro, A.: Slurry and cavitation erosion resistance of thermal spray coatings. Wear 267(1–4), 160–167 (2009)

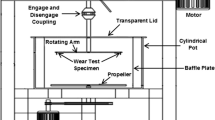

Grewal, H.S., Agrawal, A., Singh, H.: Design and development of high-velocity slurry erosion test rig using CFD. J. Mater. Eng. Perform. 22(1), 152–161 (2013)

Clark, H.M., Hawthorne, H.M., Xie, Y.: Wear rates and specific energies of some ceramic, cermet and metallic coatings determined in the Coriolis erosion tester. Wear 233–235, 319–327 (1999)

Stack, M.M., Corlett, N., Zhou, S.: Some thoughts on the effect of elastic rebounds on the boundaries of the aqueous erosion-corrosion map. Wear 214(2), 175–185 (1998)

Tabor, D.: The hardness of metals. Oxford University Press, USA (2000)

Hertz, H.: On contact of elastic solid. In: Miscellaneous papers, vol. 3. London: Macmillan, New York, Macmillan and co., (1896)

Shipway, P.H., Hutchings, I.M.: A method for optimizing the particle flux in erosion testing with a gas-blast apparatus. Wear 174(1–2), 169–175 (1994)

Papini, M., Ciampini, D., Krajac, T., Spelt, J.K.: Computer modelling of interference effects in erosion testing: effect of plume shape. Wear 255(1–6), 85–97 (2003)

Hutchings, I.M.: A model for the erosion of metals by spherical particles at normal incidence. Wear 70(3), 269–281 (1981)

Rickerby, D.G., MacMillan, N.H.: The erosion of aluminum by solid particle impingement at normal incidence. Wear 60(2), 369–382 (1980)

Levy, A., Aghazadeh, M., Hickey, G.: The effect of test variables on the platelet mechanism of erosion. Wear 108(1), 23–41 (1986)

Levy, A.V.: The platelet mechanism of erosion of ductile metals. Wear 108(1), 1–21 (1986)

Hutchings, I.M., Winter, R.E.: Particle erosion of ductile metals: A mechanism of material removal. Wear 27(1), 121–128 (1974)

Bellman Jr, R., Levy, A.: Erosion mechanism in ductile metals. Wear 70(1), 1–27 (1981)

Levy, A.V., Chik, P.: The effects of erodent composition and shape on the erosion of steel. Wear 89(2), 151–162 (1983)

Acknowledgments

Authors thankfully acknowledge the financial assistance provided by Council of Scientific and Industrial Research (CSIR), India, under project title “Development of Slurry Erosion Resistant Coatings for Hydroturbines”, File no.: 22(0604)/12/EMR-II.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Grewal, H.S., Agrawal, A. & Singh, H. Slurry Erosion Mechanism of Hydroturbine Steel: Effect of Operating Parameters. Tribol Lett 52, 287–303 (2013). https://doi.org/10.1007/s11249-013-0213-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-013-0213-z