Abstract

Tuberculosis is a very dangerous disease. Therefore, early and quick diagnosis of this disease can increase the chances of overcoming it. Studies show that people with tuberculosis have a lower blood plasma refractive index than healthy people. The performance of the fiber optic sensor based on surface plasmon resonance is investigated for the metal/oxide/graphene structure and for cases where the diameter of the fiber optic core is 300, 600, and 940 µm while blood plasma is considered as the sensing medium. The sensor characteristics such as sensitivity, detection accuracy and figure of merit are simulated for each structure using the theory of matrix method in Wolfram Mathematica software. The simulation results show that the aluminum/lutetium oxide/graphene structure has the highest quality factor when the core diameter of the optical fiber is 940 µm. In continuation of this research, the effects of using alloys with different mixture proportions to improve the quality are investigated. According to results, the structure of aluminum/copper alloy (with a ratio of 30/70)–lutetium oxide graphene is the best choice for improving the quality of the sensor.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Of course, any disease causes signs and symptoms in certain body fluids such as blood and urea [1]. Therefore, to diagnose these diseases, it may be helpful to study the blood and examine the associated properties and their changes [2]. One of the most appropriate studies is to examine the optical properties of the blood plasma. In other words, changes in the refractive index of blood plasma can be a sign of various diseases. Tuberculosis is one of the most common and dangerous diseases that can influence on the refractive index of blood plasma [3]. Tuberculosis is a widespread infectious disease, which in many cases can endanger human life. The main cause of this disease is a bacterium called Mycobacterium tuberculosis, which usually attacks the victim's lungs. The infection caused by this bacterium can also affect other parts of the body and worsen the patient's condition [4]. Tuberculosis is a contagious disease that spreads through coughing, sneezing, saliva and air. Tuberculosis infections are usually asymptomatic, but studies have shown that latent infection becomes active in one in 10 people. Therefore, tuberculosis is divided into two categories worldwide: latent and active [5]. The Manta tuberculin skin test is used to diagnose latent tuberculosis. However, the results of this test may be falsely negative in some people with underlying diseases. Usually, a blood test with x-ray examination may be helpful [6]. An accurate diagnosis of tuberculosis is critical and cannot be made definitively until a clinical specimen such as blood can prove the cause of the tuberculosis (Fig. 1). For this reason, many physicians begin prescribing antibiotics earlier [7].

From studies on the effects of tuberculosis on the blood plasma refractive index (BPRI), the normal BPRI is about 1.351, but in 90% of people with this disease, the BPRI is 1.34 or between 1.34 and 1.35. Therefore, the BPRI of people with tuberculosis is on average about 0.01 lower than healthy people [8]. This critical feature can be used to diagnose this disease. In this study, a fiber optic sensor based on surface plasmons was investigated for different structures and other sensor characteristics, for the case when the BPRI changes from 1.34 to 1.35, are calculated, and the best structure is presented at the end of the paper (Table 1). Then, a method to increase the performance of the best structure is explained, which will be discussed later [8].

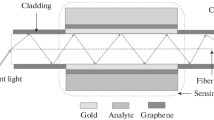

In recent decades, the use of surface plasmon resonance (SPR) has proven to be one of the best methods for fabrication and studying sensors [9]. Free electrons on the surface of metals, known as surface plasmons (SP), can produce a wave called a surface plasmon wave (SPW) that can be excited by the p-polarization of the landing field. (Solving the electromagnetic equations at the metal boundary and studying the boundary conditions show that the surface plasmon wave vector is not excited by the s-polarization.) When the surface plasmon wave vector coincides with the incident wave vector, a phenomenon called resonance occurs. This phenomenon manifests itself in the power transfer spectrum as a sharp dip [10]. One of the most famous and widely used methods for examining sensors is the Kretschmann method [11]. In this approach, a prism is used as a light transmission medium to build a sensor. One side of the prism is covered with metal layers and oxide materials and finally contacted with the sensing medium [12]. Researchers pay lots of attentions to fiber optic after its invention. Features such as cost efficiency, easy portability and simple operation are the advantages of fiber optic sensors. There are various approaches to study the performance of fiber optic sensors [13]. For example, the power transmission spectrum can be recorded in terms of wavelength, angle or phase change. Sensor characteristics such as sensitivity, detection accuracy, figure of merit and etc. can be calculated by examining the power transmission spectrum [14].

Recently, fiber optic sensors based on surface plasmon resonance have shown great potential for various medical and biophysics applications. Abdul Akib et al. designed a graphene-coated SPR biosensor for detection of the novel coronavirus [15]. An SPR based biosensor was investigated for the detection of hemoglobin in blood samples and for cancer cell by Karki et al. [16, 17]. Daher et al. have developed an SPR-based biosensor for the detection of bacteria in water [18].For fabrication, a part of fiber optic cladding is removed and replaced by a layer of metals and oxide materials. The use of single metal layers is perhaps the simplest method for fabricating these sensors [19]. Metals such as silver, gold, and copper, known as noble metals, are the most commonly used materials for sensor fabrication, but they also have drawbacks. For example, these metals are expensive and oxidize in the presence of air. Therefore, testing different structures with different compositions can open a new window for fiber optic sensors fabrication [20]. Recent researches show that the use of more complex structures such as nanocomposites, two-dimensional material layers, or even a combination of them can create better and more ideal results [21].

2 Basic theory

According to the researches, it appears that the BPRI of people with Tuberculosis is on average 0.01 lower than healthy people. (This phenomenon occurs in more than 90% of people.) The results of this study are from [8].

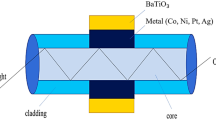

In this study, a fiber optic sensor based on surface plasmon resonance is investigated. The length of the sensor material is 10 mm. The first layer is metal (the thickness is 20 nm), the second layer is dielectric (the thickness is 40 nm), and the third layer is graphene (there are 5 layers). The optical fiber numerical aperture is considered as 0.22 while the core diameter has different values of 300,600 and 940 microns. The optical properties of each layer are listed in Fig. 2. This study investigates the effects of dielectric, metallic materials and fiber core diameter size on sensor characteristics in contact with human blood plasma. Figure 3. shows a general structure of the sensor investigated in this study. Metals such as copper, aluminum, and silver, and oxides such as lanthanum oxide, lutetium oxide, and tantalum pentoxide are considered as the first and the second layers, respectfully. The third layer is consisted of 5 Graphene layers.

In this study, the basic parameters of the sensor are investigated for the nine combinations of metals and oxides for three states. The diameter of the fiber optic core is considered as 300, 600 and 940 µm. In this study, the most suitable fiber optic sensor structure for the diagnosis of tuberculosis is presented by investigating the changes in the refractive index of blood plasma.

In this paper the sensor is simulated by using transfer matrix method(TMM) in Wolfram Mathematica software. In this method, a transfer matrix is assigned to each layer and by multiplying the layer matrices, the total transfer matrix is obtained [27].For using this approach, it is important to have accurate information about the properties of each layer through which light passes. This information is listed in theory map in Fig. 2.

The matrix method is used to calculate the p-polarization of the Fresnel reflection coefficient (Rp). The general expression for the normalized transmitted power for a fiber optic SPR sensor is given as follows [28]

where θ is supposed as the angle of the ray with the normal to the core- cladding interface and θc is the critical angle of the fiber and the refractive index of the fiber core. Nref (θ) indicates the number of light reflections in the fiber, which is defined as [29]

where L and D are the length of the exposed region and the core diameter of the fiber, respectively.

Using Snell's law, the critical angle is given as follows

where ncl is the refractive index of the fiber cladding [29].

The calculation of the optical transmission power is the key to the measurement of other sensor characteristics. Some important practical sensor properties are defined in Table 2.

3 Results and Discussion

3.1 Transmitted Output Power

The transmitted output power spectrum for the 9 structures, where the thickness of the optical fiber core is assumed to be 940 µm, is shown in Fig. 4. The wavelength range is considered in the near ultraviolet and visible regions. The spectrum of some structures is broader and some others is sharper. It seems that structures with lower spectral width have higher quality [30]. To prove this claim, the sensor characteristics will be calculated.

3.2 Sensitivity

The changes in sensitivity of the fiber optic sensor for the 9 structures are shown in Fig. 5.

Figure 5 shows that a sensor whose fiber core diameter is thicker is more sensitive. The reason for this phenomenon can be explained by the fact that by increment of optical fiber core diameter the attenuation wave that penetrates the subsequent layers will enhance, and finally the interaction of the attenuation wave with the surface plasmons and the sensing medium increases. A careful look at Fig. 5. shows that some structures are more sensitive and some are less. The details are shown in Table 3. As mentioned earlier, the fourth layer (graphene) is constant, so any changes in the sensing structure depend on the type of metal and dielectric.

The high sensitivity of some structures is due to the fact that the real part of the surface plasmon wave vector is stronger. In other words, a metal and dielectric combination with larger real part of the surface plasmon wave vector can interact more strongly with the sensing medium and is therefore more sensitive to slight changes in the refractive index of the sensing medium [31]. Ag-Lu2O3-Gr structure is introduced as the most sensitive structure, while the fiber core diameter is 940 microns.

3.3 Detection Accuracy

Another important characteristic for evaluating of a fiber optic sensor performance is its detection accuracy (DA). In general, this factor is determined by inversing the full width at half maximum (FWHM) [32]. Figure 6 shows that the sensor is more accurate when the fiber optic core is thicker. By increasing the diameter of the fiber optic core, a stronger damping wave is inhibited by surface plasmons, and finally the amplification of the surface plasmon wave vector leads to a sharper resonance in the spectrum and, reducing the FWHM of the transmission power leads to an increase in the detection accuracy of the sensor. This phenomenon is due to the fact that detection accuracy is related to FWHM inversely [32].

As shown in Fig. 6. In some structures DA is larger than others. The details are shown in Table 3. The cause of this phenomenon can be explained by the fact that in some structures the loss or damping effects are less than others (these damping are related to the extinction coefficient or the imaginary part of the dielectric coefficient). Damping factor reduction also causes the spectral width to be small, resulting in high detection accuracy. So, in general, the less the damping, the smaller the spectral bandwidth and consequently the larger the detection accuracy. According to the proposed structures, the highest DA is recorded for Al-Ta2O5-Gr while the fiber core diameter is 940 microns.

3.4 Figure of Merit

Figure 7 shows the changes of figure of merit with different structures while the fiber core has three values of 300, 600 and 940 microns. The thicker the fiber core, the larger the sensor FOM. The details are shown in Table 3. How the FOM changes for different structures is related to two properties: Sensitivity (S) and Detection Accuracy (DA). Since the FOM is obtained by multiplying the sensitivity by the detection accuracy, the sensor that simultaneously has the largest value of DA and S has a higher quality [33]. Based on the proposed structures, Al-Lu2O3-Gr compound has the highest quality, while the fiber core is 940 microns.

3.5 Method of Improvement

According to the results of the previous section, Al-Lu2O3-Gr compound has been found to be the highest quality. In the continuation of this article, a quality enhancement method is studied. Experiments and studies show that using alloys instead of pure metals leads to the enhancement of surface plasmons and improves the performance of the sensor [34]. In this study, nickel/aluminum, cobalt/aluminum, and silver/aluminum alloys with different proportions were used instead of pure aluminum to investigate the effects of these alloys on the sensor characteristics. The schematic of the fiber optic sensor consisting of an alloy layer is shown in Fig. 8. For numerical simulation the electrical permittivity of the alloy layer is needed which be defined as [35]

where εAl is the electrical permittivity of Al and εx is the electrical permittivity of Ni, Cu, and Co (guest metals) that are obtained from [24] and also x shows the percentages of the guest metal in alloy [36].

The results of Al/X alloy-Lu2O3-Gr sensor are discussed in this section. In this structure, Al is the host metal and other metals (X) such as Ni, Co and Cu are considered as the guest metals [37].

3.6 Transmitted Output Power

Figure 9 shows the transmitted output optical power for three alloys with composition ratio of (30:70). The results show that using alloys produces a sharper resonance at longer wavelengths (in the visible range). The sensor characteristics will be discussed in next sections.

3.7 Sensitivity

Figure 10 shows the sensitivity changes for three structures of Al/Ni alloy-Lu2O3-Gr, Al/Cu alloy-Lu2O3-Gr, and Al/Co alloy-Lu2O3-Gr in which the percentage of guest metals (nickel, cobalt, and copper) is 0.1, 0.3, 0.5, 0.7, and 0.9, respectively. The results show that by increment of guest metal percentage (while decreasing the amount of aluminum (host metal)) the sensitivity of the sensor will increase. Al/Co alloy-Lu2O3-Gr has the highest sensitivity and Al/Cu alloy-Lu2O3-Gr has the lowest sensitivity. The details are shown in Table 4. The results can be physically justified by the fact that guest metals can amplify the surface plasmons, and the amplification of the SP wave can improve the sensor sensitivity. On the other hand, the high sensitivity of Al/Co alloy-Lu2O3-Gr can be attributed to the large part of its dielectric coefficient compared to other alloys. Larger real part of the dielectric coefficient contributes to the amplification of the SP wave which increases the sensitivity of the sensor.

3.8 Detection Accuracy

Figure 11 shows DA changes with the percentage of guest metals in alloy. DA has the highest value where the percentage of the guest metal is 30% and then decreases as the percentage of the guest metal increases (decrease in the host metal (aluminum)). The details are shown in Table 4. The reason is related to the imaginary part of the dielectric coefficient of metals [38]. The cause of this phenomenon is the high value of the real part of the dielectric coefficient of the alloy and the small value of its imaginary part. In other words, the larger the value of the real part of the dielectric coefficient, the stronger the SP wave, the sharper the spectrum, the smaller the spectral width and, finally, the larger the DA.

3.9 Figure of Merit

As mentioned in the previous section, FOM is the result of multiplying the sensitivity by the detection accuracy, is one of the most important sensor characteristics [39]. Figure 12 shows the FOM with the percentage of guest metals in the alloy. The details are shown in Table 4. The highest value of FOM is for Al/Cu alloy (70:30)-Lu2O3-Gr. These observations can also be justified by the high sensitivity and detection accuracy of this structure.

According to the final results, Al/Cu alloy (70:30) -Lu2O3-Gr structure, on fiber optic with 0.22 numerical aperture and 940µ core diameter, shows the highest quality. Al/Cu alloy is widely used in the industry. It can be manufactured by different methods such as additive manufacturing, nanostructure designing, etc. In additive manufacturing (AM) technique, a structure can be created by depositing successive layers. This procedure has been considered an alternative, economic process for producing metallic components due to its high potential advantages of time and cost saving [36]. In the nanostructure designing method, the materials are changed into nanoparticles and then combined with different percentages [40]. Lu2O3 is a rare earth material that is wildly applied in ceramics, glass, phosphorous and lasers [41]. This is a white powder with high thermal conductivity. So, Lu2O3 can be formed as thin film by thermal deposition [42]. Graphene is a single two-dimensional layer of carbon atoms bound in a hexagonal lattice structure [43]. Graphene has many applications such as anti-corrosion coatings and paints, efficient and precise sensors, faster and efficient electronics, efficient solar panels, drug delivery, etc.[44]. One of the best solutions to graphene device fabrication is the chemical vapor deposited (CVD) method [45]. Fiber optics with 0.22 numerical aperture and 940 µm core diameter are fabricated by many companies. As mentioned above, all components of this structure (Al/Cu alloy, Lu2O3 and Graphene) are available and can be formed as thin films to deposit on the fiber optic by regular and affordable methods. Based on Al/Cu alloy (70:30) -Lu2O3-Gr potential for detecting Tuberculosis and easy fabrication, it can be considered a feasible practical project.

4 Conclusion

In this work, a fiber optic sensor based on surface plasmon resonance for diagnosis of tuberculosis due to changes in the refractive index of blood plasma was simulated numerically by TMM method using Wolfram Mathematica software. Sensor characteristics such as sensitivity, detection accuracy, and figure of merit were also studied. The calculations were done in two stages. In the first part, an optical fiber sensor consisting of metal/oxide/graphene layers was simulated, while the fiber core diameter was 300, 600, and 940 microns. Al-Lu2O3-Gr while the optical fiber core diameter is 940 µm is introduced as the winning structure. In general, when the real part of the dielectric coefficient is larger, the surface plasmon wave vector becomes stronger and therefore the structure is more sensitive to slight changes in the refractive index of the sensing medium (blood plasma). In addition, the small imaginary part of the dielectric coefficient leads to a reduction in losses and a smaller spectral width, increasing the detection accuracy of the sensor. In fact, a sensor that simultaneously has higher detection accuracy and sensitivity is the most suitable. In the second part of this paper, the effect of using Al/Ni, Al/Cu, and Al/Co alloys instead of pure Al is investigated for different percentages to enhance the surface plasmon wave. Al/Cu alloy (70:30) -Lu2O3-Gr reaches the highest quality. In fact, the most important factor to achieve a desirable sensor is to use appropriate materials to produce a stronger plasmon wave and less losses.

Data Availability

The datasets generated during and/or analyzed during the current study are not publicly available due to [REASON(S) WHY DATA ARE NOT PUBLIC] but are available from the corresponding author on reasonable request.].

References

Rowe, D. J., Owens, D. R., Parker, S. L., Faust, S. N., Wilkinson, J. S., & Mashanovich, G. Z. (2021). The effect of haematocrit on measurement of the mid-infrared refractive index of plasma in whole blood. Biosensors. https://doi.org/10.3390/bios11110417

Daniel, T. M. (2006). The history of tuberculosis. Respiratory Medicine. https://doi.org/10.1016/j.rmed.2006.08.006

Reddy, N. M., Kothandan, D., Lingam, S., Chandra, & Ahmad, A. (2012). “A study on Refractive index of plasma of blood of patients suffering from Tuberculosis,” International Journal of Innovative Technology and Exploring, vol. 2, no. 8, p. 23, 2012, [Online]. Available: www.ijitce.co.uk

Pai, M., et al. (2016). Tuberculosis. Nature Reviews Disease Primers. https://doi.org/10.1038/nrdp.2016.76

Natarajan, A., Beena, P. M., Devnikar, A. V., & Mali, S. (2020). A systemic review on tuberculosis. Indian Journal of Tuberculosis. https://doi.org/10.1016/j.ijtb.2020.02.005

Yoon, H. J., Song, Y. G., Il Park, W., Choi, J. P., Chang, K. H., & Kim, J. M. (2004). Clinical manifestations and diagnosis of extrapulmonary tubercolosis. Yonsei Medical Journal. https://doi.org/10.3349/ymj.2004.45.3.453

Dholakia, Y. N., D’souza, D. T. B., Tolani, M. P., Chatterjee, A., & Mistry, N. F. (2012). Chest X-rays and associated clinical parameters in pulmonary tubercolosis cases from the National Tubercolosis Program, Mumbai, India. Infectious Disease Report. https://doi.org/10.4081/idr.2012.3438

Reddy, N. M., Kothandan, D., Lingam, S. C., & Ahmad, A. (2012). A study on refractive index of plasma of blood of patients suffering from tuberculosis. International Journal of Innovative Technology and Exploring, 2, 3.

Tabassum, R., & Kant, R. (2020). Recent trends in surface plasmon resonance based fiber–optic gas sensors utilizing metal oxides and carbon nanomaterials as functional entities. Sensors and Actuators, B: Chemical. https://doi.org/10.1016/j.snb.2020.127813

Sharma, A. K., Pandey, A. K., & Kaur, B. (2018). A Review of advancements (2007–2017) in plasmonics-based optical fiber sensors. Optical Fiber Technology. https://doi.org/10.1016/j.yofte.2018.03.008

Regatos, D., et al. (2010). Au/Fe/Au multilayer transducers for magneto-optic surface plasmon resonance sensing. Journal of Applied Physics. https://doi.org/10.1063/1.3475711

Mukhtar, W. M., Halim, R. M., Dasuki, K. A., Rashid, A. R. A., & Taib, N. A. M. (2018). “Silver-graphene oxide nanocomposite film-based SPR sensor for detection of Pb2+ ions. IEEE International Conference on Semiconductor Electronics. https://doi.org/10.1109/SMELEC.2018.8481315

Sharma, A. K., & Kaur, B. (2018). Fiber optic SPR sensing enhancement in NIR via optimum radiation damping catalyzed by 2D materials. IEEE Photonics Technology Letters. https://doi.org/10.1109/LPT.2018.2874700

Kapoor, V., Sharma, N. K., & Sajal, V. (2019). Effect of zinc oxide overlayer on the sensitivity of fiber optic SPR sensor with indium tin oxide layer. Optik (Stuttg). https://doi.org/10.1016/j.ijleo.2019.03.122

Akib, T. B. A., et al. (2021). Design and numerical analysis of a graphene-coated spr biosensor for rapid detection of the novel coronavirus. Sensors. https://doi.org/10.3390/s21103491

Mostufa, S., Paul, A. K., & Chakrabarti, K. (2021). Detection of hemoglobin in blood and urine glucose level samples using a graphene-coated SPR based biosensor. OSA Continuum. https://doi.org/10.1364/osac.433633

Karki, B., Uniyal, A., Pal, A., & Srivastava, V. (2022). Advances in surface plasmon resonance-based biosensor technologies for cancer cell detection. International Journal of Optics. https://doi.org/10.1155/2022/1476254

Daher, M. G., Taya, S. A., Colak, I., Patel, S. K., Olaimat, M. M., & Ramahi, O. (2022). Surface plasmon resonance biosensor based on graphene layer for the detection of waterborne bacteria. J. Biophotonics. https://doi.org/10.1002/jbio.202200001

Gong, W., et al. (2019). Experimental and theoretical investigation for surface plasmon resonance biosensor based on graphene/Au film/D-POF. Optics Express. https://doi.org/10.1364/oe.27.003483

Afsharnia, M., & Hamidi, S. M. (2018). Design and performance perspectives on fiber optic sensors with plasmonic nanostructures and gratings: A review. IEEE Transactions on Magnetics. https://doi.org/10.1109/TMAG.2017.2761754

Nayak, J. K., Parhi, P., & Jha, R. (2016). Experimental and theoretical studies on localized surface plasmon resonance based fiber optic sensor using graphene oxide coated silver nanoparticles. Journal of Physics. D. Applied Physics. https://doi.org/10.1088/0022-3727/49/28/285101

Sharma, A. K., & Marques, C. (2019). Design and performance perspectives on fiber optic sensors with plasmonic nanostructures and gratings: A review. IEEE Sensors Journal. https://doi.org/10.1109/JSEN.2019.2915274

Sharma, A. K., & Gupta, B. D. (2007). On the performance of different bimetallic combinations in surface plasmon resonance based fiber optic sensors. Journal of Applied Physics. https://doi.org/10.1063/1.2721779

Tabassum, R., & Gupta, B. D. (2017). Influence of oxide overlayer on the performance of a fiber optic SPR sensor with Al/Cu layers. IEEE Journal of Selected Topics in Quantum Electronics. https://doi.org/10.1109/JSTQE.2016.2553442

Lin, Z., Chen, S., & Lin, C. (2020). Sensitivity improvement of a surface plasmon resonance sensor based on two-dimensional materials hybrid structure in visible region: A theoretical study. Sensors (Switzerland). https://doi.org/10.3390/s20092445

Liu, S., Deng, Z., Li, J., Wang, J., & Huang, N. (2019). Measurement of the refractive index of whole blood and its components for a continuous spectral region. Journal of Biomedial Optics, 24(03), 1. https://doi.org/10.1117/1.jbo.24.3.035003

Zhan, T., Shi, X., Dai, Y., Liu, X., & Zi, J. (2013). Transfer matrix method for optics in graphene layers. Journal of Physics: Condensed Matter. https://doi.org/10.1088/0953-8984/25/21/215301

Shukla, S., Sharma, N. K., & Sajal, V. (2016). Theoretical analysis of surface plasmon resonance based fiber optic sensor using ITO and ZnO thin films. Optical and Quantum Electronics, 48(1), 1–9. https://doi.org/10.1007/s11082-015-0351-7

Du, B., Yang, Y., Zhang, Y., & Yang, D. (2019). SPR label-free biosensor with oxide-metal-oxide-coated D-typed optical fiber: A theoretical study. Plasmonics, 14(2), 457–463. https://doi.org/10.1007/s11468-018-0824-1

Prabowo, B. A., Purwidyantri, A., & Liu, K. C. (2018). Surface plasmon resonance optical sensor: A review on light source technology. Biosensors. https://doi.org/10.3390/bios8030080

Gupta, B. D., & Sharma, A. K. (2005). Sensitivity evaluation of a multi-layered surface plasmon resonance-based fiber optic sensor: A theoretical study. Sensors and Actuators B: Chemical. https://doi.org/10.1016/j.snb.2004.08.030

Mishra, A. K., Mishra, S. K., & Gupta, B. D. (2015). SPR based fiber optic sensor for refractive index sensing with enhanced detection accuracy and figure of merit in visible region. Optics Communication. https://doi.org/10.1016/j.optcom.2015.01.043

Meng, Q. Q., Zhao, X., Lin, C. Y., Chen, S. J., Ding, Y. C., & Chen, Z. Y. (2017). Figure of merit enhancement of a surface plasmon resonance sensor using a low-refractive-index porous silica film. Sensors (Switzerland). https://doi.org/10.3390/s17081846

Ma, H., Liu, X., Gao, C., & Yin, Y. (2020). The calculated dielectric function and optical properties of bimetallic alloy nanoparticles. Journal of Physical Chemistry C. https://doi.org/10.1021/acs.jpcc.9b11154

Sharma, A. K., & Gupta, B. D. (2006). Fibre-optic sensor based on surface plasmon resonance with Ag-Au alloy nanoparticle films. Nanotechnology, 17(1), 124–131. https://doi.org/10.1088/0957-4484/17/1/020

Cong, B., Qi, Z., Qi, B., Sun, H., Zhao, G., & Ding, J. (2017). A comparative study of additively manufactured thin wall and block structure with Al-6.3% Cu alloy using cold metal transfer process. Applied Science, 7(3), 2017. https://doi.org/10.3390/APP7030275

Barron, L. W., Neidrich, J., & Kurinec, S. K. (2007). Optical, electrical, and structural properties of sputtered aluminum alloy thin films with copper, titanium and chromium additions. Thin Solid Films. https://doi.org/10.1016/j.tsf.2006.09.030

Sharma, N., Joy, A., Mishra, A. K., & Verma, R. K. (2015). Fuchs sondheimer-drude lorentz model and drude model in the study of SPR based optical sensors: A theoretical study. Optics Communication. https://doi.org/10.1016/j.optcom.2015.08.092

Tabassum, R., & Kant, R. (2020). Cascaded wavelength multiplexed refractive index sensors in optical fibers based on surface plasmon resonances. Journal of Applied Physics. https://doi.org/10.1063/5.0017256

Murashkin, M. Y., Sabirov, I., Sauvage, X., & Valiev, R. Z. (2016). Nanostructured Al and Cu alloys with superior strength and electrical conductivity. Journal of Materials Science, 51(1), 33–49. https://doi.org/10.1007/s10853-015-9354-9

He, Y., Lai, M., & Fang, F. (2019). A numerical study on nanometric cutting mechanism of lutetium oxide single crystal. Applied Surface Science, 496(May), 143715. https://doi.org/10.1016/j.apsusc.2019.143715

Zhang, W., Yan, D., Tong, X., & Liu, M. (2018). Ultrathin lutetium oxide film as an epitaxial hole-blocking layer for crystalline bismuth vanadate water splitting photoanodes. Advanced Functional Materials, 28(10), 1–8. https://doi.org/10.1002/adfm.201705512

Cooper, D. R., et al. (2012). Experimental review of graphene. Condensed Matter Physics. https://doi.org/10.5402/2012/501686

De Abajo, F. J. G. (2014). Graphene plasmonics: Challenges and opportunities. ACS Photonics. https://doi.org/10.1021/ph400147y

Gannett, W., Regan, W., Watanabe, K., Taniguchi, T., Crommie, M. F., & Zettl, A. (2011). Boron nitride substrates for high mobility chemical vapor deposited graphene. Applied Physice Letters. https://doi.org/10.1063/1.3599708

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All the authors write and review the article together.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.”

Ethical Statement

NonE.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Esmailidastjerdipour, P., Shahshahani, F. Numerical Simulation of Surface Plasmon Resonance Optical Fiber Biosensor Enhanced by Using Alloys for Medical Application. Sens Imaging 24, 4 (2023). https://doi.org/10.1007/s11220-022-00409-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11220-022-00409-y