Abstract

The influence of support porosity on the selectivity of home-made 5%Pd–2%In/support (support = SiO2, Al2O3, TiO2) catalysts in nitrate reduction was studied. The main final products of the reaction were N2 and NH4 +. Together with the decrease in pore diameter, an increase in ammonia concentration in the reaction mixture was observed. It is probably caused by slow diffusion of OH− ions from narrow pores to the solution.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nitrates belong to the most widespread contaminants of underground and surface water from which potable water is prepared. The harmfulness of nitrates results from the possibility of their reduction to nitrites, which may take place both in water and in human digestive system. Nitrites pose a direct threat to health causing methemoglobinemia, hypertension, anaemia, inhibition of body mass growth or formation of carcinogen nitrosamines in the alimentary tract. World Health Organization sets limits on the amount of these nitrogen compounds in potable water of 50 mg/dm3 NO3 −, 0.5 mg/dm3 NO2 −, 0.5 mg/dm3 NH4 +. Due to the harmful activity of nitrates, effective methods of their degradation have to be worked out. The removal of nitrates from water with the application of biological or physicochemical methods is effective; however, these methods also have some economical and ecological disadvantages. Taking ecological aspects into account, the catalytic removal of nitrates from water seems to be a very interesting issue.

The catalytic reduction of nitrates and nitrites was conducted on mono- and bimetallic supported systems. The monometallic catalysts which were studied thoroughly are palladium systems supported on Al2O3 [1, 2], C [3–5], SnO2 [6–8], CeO2 [9], TiO2 [10, 11], and pumice [12]. Monometallic palladium catalysts are not very active in the reaction of nitrate reduction. However, they show high activity in the reduction of nitrites [3–5, 12–14]. Among the studied bimetallic systems, palladium systems promoted with Cu, Sn, Ag or Fe supported on different kinds of oxide carriers [14–20], polymers [21, 22], zeolites [23], active carbons [24–26], resin [27–29], showed the best catalytic characteristics. The mechanism of these systems has not been explained unequivocally yet. The one which is the most frequently discussed in the literature is the bifunctional mechanism, according to which nitrates are reduced to nitrites in the redox process on the metallic promoter, during the second stage nitrites are reduced to nitrogen or ammonia on a noble metal [19, 30–34]. In this mechanism, the role of possible intermetallic interaction, which may occur on the surface of bimetallic supported catalysts, was not taken into account. Moreover, there are a lot of different factors which may influence the activity and selectivity of bimetallic systems based on palladium. Considering the chemical nature of various carriers, it may be assumed that the kind of carrier as well as the way of obtaining catalysts may have an influence on the catalytic properties of bimetallic systems. What is also significant is the kind and conditions of activation of obtained catalysts, which may determine the size of dispersion of the active phase, lead to the formation of solid solutions or the creation of intermetallic compounds.

So far, the palladium supported catalysts promoted with indium have not been studied thoroughly in the catalytic reduction of nitrates [27, 35–37]. The studies that we have conducted show that palladium supported catalysts promoted with indium, after appropriate activation, are characterized by good activity and selectivity to nitrogen. For Pd–In systems supported on Al2O3 and SiO2, strong interactions between palladium and indium leading to the formation of the intermetallic compound of In0.52Pd0.48 type on the surface of carriers used [38, 39] were observed. This compound was detected by XRD technique for Pd–In/support systems which contained more than 2 wt% indium. For bimetallic Pd–In/support systems for which the presence of the intermetallic compound In0.52Pd0.48 was stated, the decrease in selectivity to nitrogen and at the same time the increase in the amount of ammonia formed during the reaction were observed.

Experimental

Preparation of catalysts

Monometallic 5%Pd/support catalysts were obtained by impregnation of supports (Al2O3—Fluka 507C; SiO2—Degussa; TiO2—P-25 Degussa) with an aqueous solution of Pd(NO3)2. To obtain Pd(NO3)2 from metallic Pd (Mennica Państwowa S.A.) and HNO3 (POCh Gliwice), MLS-1200 Mega Microvawe Digestion System (Milestone) was used.

Bimetallic 5%Pd–2%In/support catalysts were obtained by co-impregnation of supports with an aqueous solution of Pd(NO3)2 and In(NO3)3 (99.9%, Aldrich).

The catalysts were dried in air at 110 °C for 6 h, calcined in oxidizing atmosphere (500 °C, 4 h) and reduced in hydrogen atmosphere (300 °C, 2 h) directly before the measurements.

Reduction of nitrates

The hydrogenation of nitrate solutions was performed in a thermostated glass reactor equipped with a stirrer, a hydrogen supply system, a burette and a pH electrode. The ammonia formed during the reduction was neutralized by the addition of aqueous solution of HCl (50 mmol/dm3) to maintain the constant pH = 5.5 ± 0.2 in the reaction medium. The amounts of dilute solution of HCl were manually dosed from the burette when the pH reached the value of about 5.6. The reaction was conducted at 20 °C. The mixture was stirred at 500 rpm and hydrogen was bubbled through at 0.2 dm3/min. No rise in the temperature due to the heat of the reaction was observed in any of the runs since the reactor was operated with low concentration of nitrate ions (\({\text{C}}_{{{\text{NaNO}}_{3} }}=1.6\;{\text{mmol/dm}}^{3},\) 100 mg/dm3 NO3 −). No pressure control was required as the total operating pressure in the system was equal to the atmospheric pressure. Because three phases were present in the reactor, the system used is treated as a slurry reactor. For all catalytic tests, 1 g of catalyst was added to 0.25 dm3 of nitrate solution.

Samples of the reaction medium were taken every 5, 10, 20, 30, 45 and 60 min, filtered and analyzed using a liquid chromatograph LaChrom (Merck Hitachi) coupled with a variable wavelength UV detector LaChrom L-7400 (Merck Hitachi). The analytical wavelength was 210 nm. In our investigation, Merck C18 LiChrospher RP-18 (5-μm) column (250 × 4.0 mm2 i.d.) was used. The solution of octyloamine phosphorate (5 mmol/dm3, pH 6.3) was used as a mobile phase. The flow rate of octyloamine phosphorate was 1.0 cm3/min. For the samples, concentrations of NH4 + ions were analyzed spectrophotometrically with the use of an ammonia test (2.6–193 mg/dm3 NH4 +, Merck).

The results of the reduction of nitrates are expressed as conversion (X, %) and selectivities (S, %). These parameters were defined as:

where \( S_{{{{\text{NH}}_{4}}^{ + } }} ,S_{{{{\text{NO}}_{2}}^{ - } }} ,S_{{{\text{N}}_{ 2} }} \) are selectivities towards ammonia, nitrites and nitrogen, in order; C0 is the molar concentration of nitrates at the beginning of the reduction; C is the molar concentration of nitrates after time t; \( C_{{{{\text{NH}}_{4}}^{ + } }} \) is the molar concentration of ammonia after time t; and \( C_{{{{\text{NO}}_{2}}^{ - } }} \) is the molar concentration of nitrites after time t.

Characterization techniques

The volumetric method

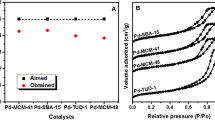

The surface area and porosity of the supports (SiO2, Al2O3, TiO2) and bimetallic 5%Pd–2%In/support catalysts were determined by the application of the BET equation and Dollim/Heal method, from the nitrogen adsorption data obtained at −196 °C (77 K) by a standard volumetric method using a Sorptomatic 1900 Carlo-Erba instrument. Samples of the carriers and catalysts were oxidized in O2 at 500 °C for 4 h, reduced in H2 at 300 °C for 2 h and then treated at 300 °C for 4 h under vacuum before the low temperature adsorption of N2 measurements. The adsorption/desorption isotherms of nitrogen and the pore diameter distribution for oxide supports (TiO2, Al2O3, SiO2) are presented in Fig. 1.

a Adsorption/desorption isotherm of nitrogen at −196 °C (77 K) for oxide supports (1 TiO2, 2 Al2O3, 3 SiO2), b pore diameter distribution for oxide supports (1 TiO2, 2 Al2O3, 3 SiO2). The samples of carriers were oxidized in O2 at 500 °C for 4 h and reduced in H2 at 300 °C for 2 h and then treated at 300 °C for 4 h under vacuum before the low temperature adsorption of N2 procedure

Powder X-ray diffraction

Room temperature powder X-ray diffraction patterns were collected using a PANalytical X’Pert Pro MPD diffractometer. The X-ray source was a copper long fine focus X-ray diffraction tube operating at 40 kV and 30 mA. Divergent optics were used in a Bragg–Brentano (flat-plate sample) geometry, with fixed divergence (1/2°) and antiscatter (1°) slits. Incident and receiving 0.04 rad Soller slits were used to limit axial divergence, and a nickel filter on the receiving side was used to eliminate CuK β radiation. Data were collected in the 2θ range 20–90° with step 0.0167° and exposition per step of 20 s. A PANalytical X’Celerator detector based on Real Time Multiple Strip technology capable of measuring the intensities simultaneously in the 2θ of 2.122° was used. Crystalline phases were identified by referring to the ICDD PDF-2 (ver. 2004) data base.

CO chemisorption measurements

Carbon monoxide chemisorption analyses were carried out in a Micromeritics ASAP 2020 apparatus. Samples were previously reduced under the same conditions as the catalysts were prepared. After reduction, the sample was subsequently cooled to room temperature under He stream (30 cm3/min). The chemisorbed carbon monoxide was analyzed at room temperature using the adsorption–backsorption isotherm method.

ICP AES analysis of reaction mixture

Indium and palladium losses from the catalysts in the reaction mixture during the catalytic tests were determined by analyzing the filtered solution by ICP with an optical emission spectrometer IRIS AP (Thermo Jarrel Ash) with horizontal observation of the plasma. The MLS—1200 Mega Microwave Digestion System (Milestone) was used for complete digestion of the samples for ICP analysis.

Result and discussion

The accepted mechanism for the reduction of nitrates to nitrites requires promotion of the noble metal by an addition of a second metal like Cu, Ag or In [19, 30–34, 39]. From the literature data, it also is known that some supports like TiO2, CeO2 and SnO2 in the monometallic palladium catalysts participate in the reduction of nitrates to nitrogen [8–11]. However, in our studies, the conversion of nitrates over 5%Pd/TiO2 was about only 3% (Table 1).

A lot of papers about sorption and catalytic properties of noble metals catalysts supported on TiO2 were published in the 1980s. The authors of those papers considered the influence of the reduction temperature on the chemisorptions of H2 and CO and on catalytic activities of M/TiO2 (M = Pt, Pd, Rh, etc.)

Tauster et al. [40, 41] from the Exxon Concern observed a significant decrease in chemisorption of those gases after reduction at 500 °C in comparison with the same systems reduced at 300 °C. For the explanation of this phenomenon, Tauster introduced the concept of Strong Metal Support Interaction (SMSI). The effect SMSI is connected with the partial reduction of titanium oxide. Assuming the formation of the reduced forms of TiO2 (TiOx), the promoting effect of TiO2 can be expected in the reduction of nitrates. However, the samples of 5%Pd/TiO2 used in our studies were reduced only at 300 °C. There is also evidence [42, 43] that TiO2 at 300 °C atmosphere may be reduced by conversion of O2− ions into the OH− ions, but the formation of anionic vacancies requires the use of a higher temperature (about 500 °C). The reduction of our samples at the temperature of 300 °C does not lead to a change in the chemical state of TiO2 surface. This is probably the main reason for the low activity of our 5%Pd/TiO2 catalyst in the reduction of nitrates. Similar results connected with the activity of monometallic palladium catalysts supported on titanium oxide were obtained by Zhang et al. [19].

The catalytic properties of selected 5%Pd–2%In/support (support = Al2O3, SiO2, TiO2) systems were studied in the hydrogenation of nitrates (100 mg/dm3 NO3 −) at room temperature and under atmospheric pressure. The bimetallic catalyst 5%Pd–2%In/Al2O3 showed both good activity and selectivity [38] and that is why catalysts with the same composition supported on various carriers (Al2O3, SiO2, TiO2) were used to study the influence of the support porosity on their catalytic properties. The supports used differed as regards their surface area and pore structure.

Fig. 2a shows the conversion of nitrates for the catalysts containing 5%Pd–2%In/Al2O3, 5%Pd–2%In/SiO2, 5%Pd–2%In/TiO2. In the case of bimetallic catalysts supported on TiO2 and Al2O3 in the reaction mixture, only trace amounts of nitrate were detected after 30 min of the reaction run. The reduction process of nitrates on 5%Pd–2%In/SiO2 was a bit slower. It is worth emphasizing that supported palladium–indium catalysts show high activity, irrespective of the support used.

Conversion of nitrates (X) (a) and selectivities to nitrites (SNO2 −) (b), ammonium (SNH3) (c) and nitrogen (SN2) (d) in the presence of catalysts: 5%Pd–2%In/Al2O3 (open triangle); 5%Pd–2%In/SiO2 (open circle); 5%Pd–2%In/TiO2 (times symbol ) during nitrate removal. Reaction conditions: T = 20 °C; mcat = 1 g; \( {\text{V}}_{{{{\text{NO}}_{3}}^{ - } }} = 0. 2 5 \;{\text{dm}}^{ 3} ;{\text{ C}}_{{0{{\text{ NO}}_{3}}^{ - } }} = 0. 1 6\;{\text{mmol}}/{\text{dm}}^{ 3} ;{\text{ pH}} = 5. 5 \pm 0. 2;{\text{ V}}_{{{\text{H}}_{2} }} = 0. 2\; {\text{dm}}^{ 3} /{ \min } \)

The analysis of the reaction mixture on the contents of nitrates (NO3 −), nitrites (NO2 −) and nitrous oxide (N2O) was conducted with the HPLC method. The obtained results show that nitrites are present in the reaction mixture only in the initial stage of the reaction for 5%Pd–2%In/Al2O3 and 5%Pd–2%In/SiO2 catalysts. The presence of this product was not observed in the case when 5%Pd–2%In/TiO2 was used. For all the studied catalytic systems, trace amounts of N2O were observed in the reaction mixture. However, its quantitative analysis was difficult to estimate.

One of the possible final products of the reduction of nitrates is ammonia. It is an undesirable product because it has toxic properties. Fig. 2c shows the influence of support used in 5%Pd–2%In/support systems (support = Al2O3, SiO2, TiO2) on the selectivity toward ammonia in the studied reaction. Irrespectively of the support used, the presence of ammonia was detected in the reaction mixture. However, its amount depended on the kind of support used. In the case of 5%Pd–2%In/TiO2 catalyst, the amount of ammonia formed in the reaction was the lowest. At the same time, this system showed the highest selectivity to nitrogen (Fig. 2d).

Because of the good catalytic properties of supported Pd–In systems in the reduction of nitrates, a series of experiments to establish their stability was conducted. The stability of each system was determined on the basis of activity changes during 12 reaction cycles (1 cycle = 60 min). The reduction of nitrates was conducted for the constant amount of catalyst (mcat = 1 g) without its removal from the reaction mixture in the subsequent cycles. After each cycle, an additional portion of nitrates (100 mg/dm3 NO3 −) was introduced to the reaction mixture.

Among the studied catalysts (5%Pd–2%In/Al2O3, 5%Pd–2%In/SiO2, 5%Pd–2%In/TiO2), the best stability was observed for 5%Pd–2%In/TiO2 system, in the case of which even after the 10th reaction cycle, practically constant conversion of nitrates was observed (Fig. 3a). What is more, this system showed high selectivity to nitrogen in all the catalytic cycles (SN2 > 80%) (Fig. 3b).

Conversion degree of nitrates after the following twelfth reaction cycle (a), selectivities to nitrogen (SN2) (b) and ammonia (SNH3) (c) after the following twelfth reaction cycle in the presence of catalysts: 5%Pd–2%In/Al2O3 (open triangle); 5%Pd–2%In/SiO2 (open circle); 5%Pd–2%In/TiO2 (times symbol ) as a function of time. Reaction conditions: T = 20 °C; mcat = 1 g; \( {\text{V}}_{{{{\text{NO}}_{3}}^{ - } }} = 0. 2 5 \;{\text{dm}}^{ 3} ;{\text{ C}}_{{0{{\text{ NO}}_{3}}^{ - } }} = 0. 1 6\;{\text{mmol}}/{\text{dm}}^{ 3} ;{\text{ pH}} = 5. 5 \pm 0. 2;{\text{ V}}_{{{\text{H}}_{2} }} = 0. 2\; {\text{dm}}^{ 3} /{ \min } \)

For the catalysts 5%Pd–2%In/Al2O3 and 5%Pd–2%In/SiO2, the conversion degree was lower and reached the value of about 70% after the 12th reaction cycle. In this case, a gradual increase in ammonia concentration was observed. It was especially seen for the 5%Pd–2%In/SiO2 catalyst.

Additional information about the stabilities of those bimetallic catalysts results from the ICP analysis of concentrations of Pd and In in the reaction mixture (Table 2). After 1 h of the reaction run, the presence of indium was never detected by the ICP analysis. For the 5%Pd–2%In/SiO2 and 5%Pd–2%In/Al2O3 systems, only the presence of a trace amount of Pd in the reaction mixture was found. For the 5%Pd–2%In/TiO2 catalyst, no transition of Pd and In into the solution was observed.

Palladium–indium catalysts were supported on SiO2, Al2O3 and TiO2. It is generally known that the kind of carrier used in the preparation of metallic supported catalysts has an influence on the dispersion of active phase [9, 28, 44]. The different dispersion of the metallic phase can impact on the activity and selectivity of the studied catalysts. The dispersion of 5%Pd/support and 5%Pd–2%In/support catalysts was estimated on the basis of chemisorptions of CO and by the XRD technique (Table 1).

On the basis of literature data, [19, 31, 34, 44] the selectivity to N2 is higher for the catalysts with lower dispersion. We observed the same tendency, but only for the monometallic palladium catalysts (Table 1). However, in the case of Pd–In/support catalysts, this tendency is not so clear. For the 5%Pd–2%In/SiO2 catalyst, the lowest value of selectivity to nitrogen was observed while the size of crystallites was the biggest. For the 5%Pd–2%In/Al2O3 and 5%Pd–2%In/TiO2 catalysts, the dispersion is comparable, but the selectivity to N2 is the highest for the system supported on TiO2. This behavior is probably connected not only with the dispersion but also with the porosity and the presence of intermetallic PdxIny compounds on the surface. Those intermetallic compounds were observed for all Pd–In/support catalysts by ToF–SIMS technique independently of the In amount incorporated to the system (Table 1). The presence of the PdxIny phase was also confirmed by the XRD technique, but only for the system with the amount of indium higher than 2-wt% [38, 39].

Our results presented in Table 1 prove that the 5%Pd–2%In/TiO2 the system shows the best catalytic properties in the studied reaction. Varied behavior of 5%Pd–2%In/support (support = Al2O3, SiO2, TiO2) systems researched by us, for which the presence of the intermetallic phase In0.52Pd0.48 was not observed by the XRD technique, suggests the influence of support porosity on selectivity of these systems toward ammonia.

The surface area and the porosity of the supports used were determined on the basis of the low-temperature adsorption of nitrogen. Fig. 1 presents adsorption/desorption isotherms and pore diameter distribution of TiO2, Al2O3 and SiO2. The influence of the introduction of metals (palladium and indium) on the porosity of the supports is presented in Fig. 4. The physicochemical characteristics of the studied supports and bimetallic 5%Pd–2%In/support catalysts are summarized in Table 3.

Pore diameter distribution for: a TiO2 (continuous line) and 5%Pd–2%In/TiO2 (dashed line) and b Al2O3 (continuous line) and 5%Pd–2%In/Al2O3 (dashed line) samples. The samples of carriers were oxidized in O2 at 500 °C for 4 h and reduced in H2 at 300 °C for 2 h and then treated at 300 °C for 4 h under vacuum before the low temperature adsorption of N2 procedure

From the presented results, it can be noticed that the supports used varied significantly as regards their texture. The surface area of SiO2 is the highest (about 300 m2/g) and the predominant pore diameter is about 45 Å. TiO2 was characterized by completely different textural parameters (a broad range of pore diameters 100–300 Å, small surface area about 50 m2/g).

The presented results prove that the incorporation of the metals into the carrier structures leads to the decrease in the surface area and the increase in the dominant diameter of the capillary. However, the trends observed for the supports are the same as those in the bimetallic catalysts supported on these carriers.

In the reduction of nitrates, maintaining constant pH [2, 8, 30, 45–47] is an important factor determining the composition of the reaction mixture. The reduction of nitrates may be schematically presented as a sequence of five reaction equations [7]:

From the presented equations, it can be seen that the reduction of NO3 − and NO2 − ions generates OH− ions in the reaction mixture. From the literature data, it is known that the formation of ammonia is strongly favored in the basic solution [48–51]. Therefore, the processes of catalytic reduction of nitrates are usually conducted in the slightly acidic reaction medium (pH 5–6). However, if OH− ions are formed on active centers located in the narrow pore structure, their neutralization is difficult and may take place after their diffusion from pores to the reaction mixture. Despite the intensive stirring (500 rpm) the local pH inside the pores may be higher than the one measured for the solution which may contribute to an increase in the ammonia formed during the reaction. Analyzing the obtained results of our research on the selectivity of Pd–In/support in the reduction of nitrates and the results of the measurements of pore structure and the surface area of the supports used, it can be stated that, together with the increase in the surface area and the decrease in the pore diameters, an increase in ammonia concentration in the reaction mixture was observed. Therefore, it can be assumed that the catalysts’ selectivity to ammonia may be caused, to a large degree, by the slow diffusion of OH− ions from the narrow pores to the solution (mass transfer phenomenon). Similar results were obtained by D’Arino et al. studying palladium and platinum catalysts supported on SnO2 of different texture [7].

Conclusions

Supported palladium-indium catalysts studied by us show high activity and stability in the reduction of nitrates. The main final products of the reaction were nitrogen (N2) and ammonia (NH4 +). The amounts of ammonia formed in the reduction of nitrates on supported Pd–In systems depend on mutual interactions between Pd and In and also on the porosity of the supports used.

From the results presented in this paper, it can also be seen that together with the increase in the surface area of the supports and the decrease in the pore diameter, the increase in ammonia concentration in the reaction mixture was observed. It is probably caused by slow diffusion of OH− ions from the narrow pores to the solution (mass transfer phenomenon). A local increase in pH of the reaction mixture in pores may contribute to the formation of larger amounts of ammonia, which is confirmed by literature data.

References

Karski S, Witońska I, Gołuchowska J (2005) Pol J Environ Stud 14:199–202

Pintar A, Berčič G, Levec J (1998) AIChE J 44:2281–2292

Calvo L, Gilarranz MA, Casas JA, Mohedano AF, Rodriguez JJ (2010) Ind Eng Chem Res 49:5603–5609

Soares OSGP, Ófrão JJM (2008) Catal Lett 126:253–260

Reddy KJ, Lin J (2000) Water Res 34:995–1001

Ambonguilat S, Gallard H, Garron A, Epron F, Croué JP (2006) Water Res 40:675–682

D’Arino M, Pinna F, Strukul G (2004) Appl Catal B Environ 53:161–168

Gavagnin R, Biasetto L, Pinna F, Strukul G (2002) Appl Catal B Environ 38:91–99

Epron F, Gauthard F, Barbier J (2002) J Catal 206:363–367

Sá J, Anderson JA (2008) Appl Catal B Environ 77:409–417

Sá J, Berger T, Föttinger K, Riss A, Anderson JA, Vinek H (2005) J Catal 234:282–291

Deganello F, Liotta LF, Macaluso A, Venezia AM, Deganello G (2000) Appl Catal B Environ 24:265–273

Pfaff C, Melo L, Betancourt P (2002) React Kinet Catal Lett 77:263–266

Witońska I, Karski S, Frajtak M, Krawczyk N, Królak A (2008) Reac Kinet Catal Lett 93:241–248

Palomares AE, Franch C, Corma A (2010) Catal Today 149:348–351

Constantinou CL, Costa CN, Efstathiou AM (2010) Catal Today 151:190–194

Xu Z, Chen L, Shao Y, Yin D, Zheng S (2009) Ind Eng Chem Res 48:8356–8363

Witońska I, Karski S, Krawczyk N, Królak A (2009) Pol J Environ Stud 18:259–263

Zhang F, Miao S, Yang Y, Zhang X, Chen J, Guan N (2008) J Phys Chem C 112:7665–7671

Witońska I, Karski S, Gołuchowska J (2007) React Kinet Catal Lett 90:107–115

Doduche I, Barbosa DP, Rangel MC, Epron F (2009) Appl Catal B Environ 93:50–55

Guy KA, Xu H, Yang JC, Werth CHJ, Shapley JR (2009) J Phys Chem C 113:8177–8185

Nakamura K, Yoshida Y, Mikami I, Okuhara T (2006) Appl Catal B Environ 65:31–36

Soares OSGP, Ófrão JJM, Pereira MFR (2009) Appl Catal B Environ 91:441–448

Matatov-Meytal U, Sheintuch M (2009) Catal Commun 10:1137–1141

Sakamoto Y, Kanno M, Okuhara T, Kamiya Y (2008) Catal Lett 125:392–395

Neyeriz C, Marchesini FA, Boix A, Miró E, Querini CA (2010) Appl Catal A Gen 372:40–47

Gašparovičová D, Králik M, Hronec M, Vallušová Z, Vinek H, Corain B (2007) J Mol Catal A 264:93–102

Gašparovičová D, Králik M, Hronec M, Biffis A, Zecca M, Corain B (2006) J Mol Catal A 244:258–266

Vorlop KD, Tacke T (1989) Chem Ing Tech 61:836–837

Yoshinaga Y, Akita T, Mikami I, Okuhara T (2002) J Catal 207:37–45

Gao W, Guan N, Chen J, Guan X, Jin R, Zeng H, Liu Z, Zhang F (2003) Appl Catal B Environ 46:341–351

Warna J, Turunen I, Salmi T, Maunula T (1994) Chem Eng Sci 49:5763–5773

Gauthard F, Epron F, Barbier J (2003) J Catal 220:182–191

Marchesini FA, Gutierrez LB, Querini CA, Miró EE (2010) Chem Eng J 159:203–211

Chaplin BP, Shapley JR, Werth CJ (2009) Catal Lett 130:56–62

Marchesini FA, Irusta S, Querini C, Miró E (2008) Appl Catal A Gen 348:60–70

Witońska I, Karski S, Rogowski J, Krawczyk N (2008) J Mol Catal A 287:87–94

Witońska I, Karski S, Krawczyk N, Królak A, Frajtak M (2009) VIII international conference, Mechanism of catalytic reactions, vol 1, Novosibirsk, p 90

Tauster SJ, Fung SC, Garten RL (1978) J Am Chem Soc 100:170–175

Tauster SJ, Fung SC (1978) J Catal 55:29–35

Haller GL, Resasco DE (1989) Adv Catal 36:173–235

Tauster SJ (1987) Acc Chem Res 20:389–394

Garron A, Lázár K, Epron F (2005) Appl Catal B Environ 59:57–69

Vorlop KD, Hörold S, Pohlandt K (1992) Chem Ing Tech 64:82–83

Hörold S, Tacke T, Vorlop KD (1993) Environ Technol 14:931–939

Vorlop KD, Prüsse U (1999) In: Jansen FJJG, VanSanten RA (eds) Catalytic science series, vol 1. Environmental catalysis, chap 10. Imperial College Press, London, pp 195–207

Hörold S, Vorlop KD, Tacke T, Sell M (1993) Catal Today 17:21–30

Strukul G, Pinna F, Marella M, Meregalli L, Tomaselli M (1996) Catal Today 27:209–214

Pintar A, Batista J, Levec J, Kajiuchi T (1996) Appl Catal B Environ 11:81–98

Pintar A, Setinc M, Levec J (1998) J Catal 174:72–87

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Krawczyk, N., Karski, S. & Witońska, I. The effect of support porosity on the selectivity of Pd–In/support catalysts in nitrate reduction. Reac Kinet Mech Cat 103, 311–323 (2011). https://doi.org/10.1007/s11144-011-0321-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-011-0321-4