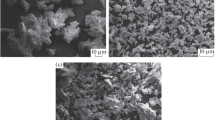

In this study, CuSn10 metal-matrix composites (MMCs) reinforced with 0, 1, 3, and 5 vol.% graphite particulates were fabricated by powder metallurgy. The microstructure, relative density, hardness, and abrasive wear behavior of the composites were investigated. The abrasive wear tests were conducted on unreinforced matrix and CuSn10–graphite composites using a pin-on-disk-type machine. The effects of sliding distance, applied load, graphite particle content, and abrasive grit sizes on the abrasive wear properties of the composites have been evaluated. The microstructure evolution of composites and the main wear mechanisms were identified using a scanning electron microscope and an energy-dispersive X-ray spectrometer (EDS). The density and hardness of the sintered CuSn10–graphite composites decreased with increasing graphite content. The abrasive wear resistance increased with increasing graphite content, but the abrasive wear resistance decreased with increasing sliding distance, applied load, and abrasive grit size. Moreover, the wear resistance of the composite was found to be considerably higher than that of the CuSn10 matrix alloy and increased with increasing graphite particle content.

Access this article

We’re sorry, something doesn't seem to be working properly.

Please try refreshing the page. If that doesn't work, please contact support so we can address the problem.

Similar content being viewed by others

References

M. Kök, “Abrasive wear of Al2O3 particle reinforced 2024 aluminum alloy composites fabricated by vortex method,” Composites: Part A, 37, 457–464 (2006).

A. Canakci, “Microstructure and abrasive wear behavior of B4C particle reinforced 2014 Al matrix composites,” J. Mater. Sci., 46, 2805–2813 (2011).

P. Abachi, A. Masoudi, and K. Purazrang, “Dry sliding wear behavior of SiCp/QE22 magnesium alloy matrix composites,” Mater. Sci. Eng. A, 435–436, 653–657 (2006).

A. K. Srivastava and K. Das, “The abrasive wear resistance of TIC and (Ti,W)C-reinforced Fe–17Mn austenitic steel matrix composites,” Tribol. Int., 43, 944–950 (2010).

G. B. Veeresh Kumar, C. S. P. Rao, and N. Selvaraj, “Studies on mechanical and dry sliding wear of Al6061–SiC composites,” Composites: Part B, 43, 1185–1191 (2012).

G. Cui, Q. Bi, S Zhu, et al., “Tribological properties of bronze–graphite composites under sea water condition,” Tribol. Int., 53, 76–86 (2012).

T. Futami, M. Ohira, H. Muto, et al., “Indentation contact behavior of copper–graphite particulate composites: Correlation between the contact parameters and the electrical resistivity,” Carbon, 46, 671–678 (2008).

D. Lu, M. Gu, and Z. Shi, “Materials transfer and formation of mechanically mixed layer in dry sliding wear of metal matrix composites against steel,” Tribol. Lett., 6, 57–61 (1999).

Y. Zhan and G. Zhang, “Friction and wear behavior of copper matrix composites reinforced with SiC and graphite particles,” Tribol. Lett., 17, 91–98 (2004).

B. Chen, Q. Bi, J. Yang, et al., “Tribological properties of solid lubricants (graphite, h-BN) for Cubased P/M friction composites,” Tribol. Int., 41, 1145–1152 (2008).

C. S. Ramesha, C. K. Srinivas, and B. H. Channabasappa, “Abrasive wear behavior of laser sintered iron– SiC composites,” Wear, 267, 1777–1783 (2009).

K. S. Al-Rubaie, H. N. Yoshimura, and J. D. Biasoli de Mello, “Two-body abrasive wear of Al–SiC composites,” Wear, 233–235, 444–454 (1999).

D. P. Mondal, S. Das, A. K. Jha, et al., “Abrasive wear of Al alloy–Al2O3 particle composite: a study on the combined effect of load and size of abrasive,” Wear, 223, 131–138 (1998).

14. B. K. Prasad, S. Das, A. K. Jha, et al., “Factors controlling the abrasive wear response of a zinc-based alloys silicon carbide particle composite,” Composite Part A, 28, 301–308 (1997).

C. Meric, E. Atik, and H. Kacar, “Effect of aging on the abrasive wear properties of AlMgSi1 alloy,” Mater. Des., 27, 1180–1186 (2006).

O. S. Yilmaz, “Comparison on abrasive wear of SiCrFe, CrFeC, and Al2O3 reinforced Al2024 MMCs,” Tribol. Int., 40, 441–452 (2007).

B. K. Prasad, A. K. Jha, O. P. Modi, et al., “Abrasive wear characteristics of Zn–37.2 Al–2.5 Cu–0.2 Mg alloy dispersed with silicon carbide particles,” Mater. Trans., 36(8), 1048–1057 (1995).

Y. Sahin and K. Ozdin, “A model for the abrasive wear behavior of aluminum based composites,” Mater. Des., 29, 728–733 (2008).

E. Hornbogen, “Role of fracture toughness in wear of metals,” Wear, 33, 251–259 (1975).

M. Kestursatya, J. K. Kim, and P. K. Rohatgi, “Wear performance of copper–graphite composite and a leaded copper alloy,” Mater. Sci. Eng. A, 339, 150–158 (2003).

M. Ghorbani, M. Mazaheri, and A. Afshar, “Wear and friction characteristics of electrodeposited graphitebronze composite coatings,” Surf. Coat. Technol., 190, 32–38 (2005).

W. L. Ma and J. J. Lu, “Effect of sliding speed on surface modification and tribological behavior of copper–graphite composite,” Tribol. Lett., 41, 363–70 (2011).

K. A. Ragab, R. Abdel-Karim, S. Farag, et al., “Influence of SiC, SiO2 and graphite on corrosive wear of bronze composites subjected to acid rain,” Tribol. Int., 43, 594–601 (2010).

H. Y. Wang, Q. C. Jiang, Y. Wang, et al., “Fabrication of TiB2 particulate reinforced magnesium matrix composites by powder metallurgy,” Mater. Lett., 58, 3509–3513 (2004).

K. Rajkumar and S. Aravindan, “Tribological performance of microwave sintered copper–TiC–graphite hybrid composites,” Tribol. Int., 44, 347–358 (2011).

A. Canakci, S. Ozsahin, and T. Varol, “Modeling the influence of a process control agent on the properties of metal matrix composite powders using artificial neural networks,” Powder Tec., 228, 26–35 (2012).

M. Alizadeh and M. M. Aliabadi, “Synthesis behavior of nanocrystalline Al–Al2O3 composite during low time mechanical milling process,” J. Alloys Compd., 509, 4978–4986 (2011).

G. Celebi Efe, T. Yener, I. Altinsoy, et al., “The effect of sintering temperature on some properties of Cu– SiC composite,” J. Alloys Compd., 509, 6036–6042 (2011).

Z. Razavi Hesabi, H. R. Hafizpour, and A. Simchi, “An investigation on the compressibility of aluminum/nano-alumina composite powder prepared by blending and mechanical milling,” Mater. Sci. Eng. A , 454–455, 89–98 (2007).

M. A. Islam and Z. N. Farhat, “Effect of porosity on dry sliding wear of Al–Si alloys,” Tribol. Int., 44, 498–504 (2011).

A. Canakci, T. Varol, and S. Ertok, “The effect of mechanical alloying on Al2O3 distribution and properties of Al2O3 particle reinforced Al-MMCs,” Sci. Eng. Compos. Mater., 19, 227–235 (2012).

A. Canakci, T. Varol, and C. Nazik, “Effects of amount of methanol on characteristics of mechanically alloyed Al–Al2O3 composite powders,” Mater. Technol., 27, 320–327 (2012).

M. A. Thein, L. Lu, and M. O. Lai, “Effect of milling and reinforcement on mechanical properties of nanostructured magnesium composite,” J. Mater. Process. Technol., 209, 4439–4443 (2009).

J. J. Coronado and A. Sinatora, “Effect of abrasive size on wear of metallic materials and its relationship with microchips morphology and wear micromechanisms: Part 2,” Wear, 271, 1804–1812 (2011).

T. O. Mulhearn and L. E. Samuels, “The abrasion of metals: a model of the process,” Wear, 5, 478–98 (1962).

J. Larsen-Basse, “Some effects of specimen size on abrasive wear,” Wear, 19, 27–35 (1972).

R. W. Johnson, “A study of the pickup of abrasive particles during abrasion of annealed aluminum on silicon carbide abrasive,” Wear, 16, 351–358 (1970).

H. Sin, N. Saka, and N.P. Suh, “Abrasive wear mechanisms and grit size effect,” Wear, 55, 163–90 (1979).

G. Srinath and R. Gnanamoorthy, “Two-body abrasive wear characteristics of Nylon clay nanocomposites: effect of grit size, load, and sliding velocity,” Mater. Sci. Eng. A, 435–436 181–186 (2006).

A. A. Torrance, “The effect of grit size and asperity blunting on abrasive wear,” Wear, 253, (2002) 813–819.

E. Candan, H. Ahlatei, and H. Cimenoglu, “Abrasive wear behavior of Al–SiC composites produced by pressure infiltration technique,” Wear, 241, 33–40 (2000).

C. Suiyuan, W. Jing, L. Yijie, et al., “Synthesis of new Cu-based self-lubricating composites with great mechanical properties,” J. Comp. Mater., 45, 51–63 (2011).

J. J. Coronado and A. Sinatora, “Load effect in abrasive wear mechanism of cast iron with graphite and cementite,” Wear, 267, 6–11 (2009).

P. Ravindran, K. Manisekar, and R. Narayanasamy, “Tribological behavior of powder metallurgyprocessed aluminum hybrid composites with the addition of graphite solid lubricant,” Ceram. Int., 39, 1169–1182 (2013).

Z. Mei-juan, Y. Xiao-hong, L. Yong-bing, et al., “Effect of graphite content on wear property of graphite/ Al2O3/Mg–9Al–1Zn–0.8Ce composites,” Trans. Nonferrous Met. Soc. China, 20, 207–211 (2010).

B. M. Girish, K. R. Prakash, B. M. Satish, et al., “Need for optimization of graphite particle reinforcement in ZA-27 alloy composites for tribological applications,” Mater. Sci. Eng. A, 530, 382–388 (2011).

M. Mosleh, P. J. Blau, and D. Dumitrescu, “Characteristics and morphology of wear particles from laboratory testing of disk brake materials,” Wear, 256, 1128–1134 (2004).

U. Cho and J. A. Tichy, “Quantitative correlation of wear debris morphology: grouping and classification,” Tribol. Int., 33, 461–467 (2000).

Acknowledgments

The authors are grateful to the Karadeniz Technical University Research Fund for financial support to this research (No. 2010.112.0105).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Poroshkovaya Metallurgiya, Vol. 53, No. 5–6 (497), pp. 32–47, 2014.

Rights and permissions

About this article

Cite this article

Canakci, A., Cuvalci, H., Varol, T. et al. Microstructure and Abrasive Wear Behavior of CuSn10–Graphite Composites Produced by Powder Metallurgy. Powder Metall Met Ceram 53, 275–287 (2014). https://doi.org/10.1007/s11106-014-9614-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-014-9614-2