Abstract

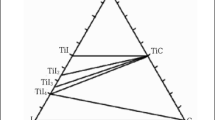

The structure and phase composition of the products of combined carbothermal reduction of titanium and niobium (tantalum) oxides with an excess of carbon are studied. It is established that formation of solid solutions (Ti, Nb)C and (Ti, Ta)C occurs through successive stages of synthesis of the individual carbides followed by dissolution of TiC in NbC (TaC). Excess of carbon provides high dispersion of the reduction products and their purity with respect to oxygen. Features of solid solution (Ti, Nb)C formation with interaction of niobium oxide and titanium carbide with an excess of carbon (12 mass%) are studied. Use of fine-grained titanium carbide, pure with respect to oxygen, with excess carbon made it possible to reduce by 300 °C the temperature for forming homogenous solid solution and to obtain powder with a particle size of less than 8 µm without grinding.

Similar content being viewed by others

References

T. Vasile, C. Sfat, M. Vasilescu, and G. Zafiu, “The improvement of WC-TiC-Co performances realized by addition of (Ta, Nb)C,” Proc. 15th Internat. Plansee Seminar “Plansee Holding AG,” Vol. 2, Reutte (2001).

G. Mori, H. Zitter, A. Lackner, and M. Schretter, “Influencing the corrosion resistance of cemented carbides by addition of Cr2C3, TiC and TaC,” Proc. 15th Internat. Plansee Seminar “Plansee Holding AG,” Vol. 2, Reutte (2001).

V. I. Tret’yakov, Cermet Hard Alloys [in Russian], Metallurgiya, Moscow (1962).

É. V. Prilutskii, A. Saltyvaldiev, and U. A. Usanov, Carbides and Materials Based on Them [in Russian], Kiev (1991), 45 pp. (Preprint / Institute for Problems of Materials Science, National Academy of Sciences of Ukraine).

R. Kiffer and F. Benezovskii, Hard Materials [in Russian], Metallurgiya, Moscow (1968).

G. V. Samsonov, A. T. Pilipenko, and T. M. Nazarchuk, Analysis of Hard Refractory Compounds [in Ukrainian], Vid. AN URSR, Kiev (1961).

T. Ya. Kosolapova (ed.), Properties, Preparation and Use of Refractory Compounds: Handbook [in Russian] Metallurgiya, Moscow (1986).

F. M. D’Heurle, “Diffusion in silicides,” Le Vide, Les Conches Minces, 42, No. 236, 172–176 (1987).

G. Sh. Upadkhaya, Physical Properties of Transition Metal Monocarbides of the IV-V Groups and Their Alloys in the Region of Homogeneity, PhD Thesis [in Russian], Kiev (1969).

Author information

Authors and Affiliations

Additional information

__________

Translated from Poroshkovaya Metallurgiya, Nos. 1–22(447), pp. 19–25, January–February, 2006.

Rights and permissions

About this article

Cite this article

Kud’, I.V., Likhoded, L.S., Eremenko, L.I. et al. Features of (Ti, Me)C solid solution formation. Powder Metall Met Ceram 45, 14–19 (2006). https://doi.org/10.1007/s11106-006-0036-7

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11106-006-0036-7