Abstract

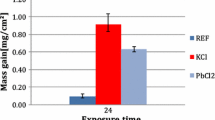

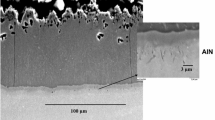

In modern fossil power plants, biomass is used more and more as secondary fuel in addition to coal. This leads to a significant decrease of the carbon footprint of such power plants. However, the demands on the corrosion resistance of the materials in the boilers increase because of chlorine in the atmosphere and salt-containing sulfides and chlorides. Heat-resistant ferritic–martensitic steels such as P91 are of great interest as superheater material. However, their corrosion resistance has to be improved for an application in modern fossil power plants with biomass combustion. For this purpose, chromium and aluminum diffusion coatings were developed and applied on P91 steel. The uncoated and coated material was investigated in a simulated biomass–brown coal ash with CaSO4, Na2SO4, K2SO4, KCl, and Al2O3 deposits and an atmosphere containing nitrogen with H2O, CO2, O2, SO2, and HCl. The improvement of the corrosion resistance is illustrated using metallographic methods such as electron probe micro-analysis.

Similar content being viewed by others

References

P. J. Ennis and W. J. Quadakkers, VGB PowerTech 8, 2001 (87).

P. Kofstad, High Temperature Corrosion, (Elsevier Applied Science, London, 1988).

E. A. Gulbransen and K. F. Andrew, Journal of The Electrochemical Society 99, 1952 (402).

F. Dettenwanger, M. Schorr, J. Ellrich, T. Weber and M. Schütze, in Lifetime Modelling of High Temperature Corrosion Processes-Proceeding of an EFC workshop, eds. M. Schütze, W. J. Quadakkers, and J. R. Nicholls, (Maney Publishing, London, 2001), p. 206.

X. Montero and M. C. Galetz, Oxidation of Metals 83, 2015 (485).

A. Soleimani-Dorcheh, R. N. Durham and M. C. Galetz, Solar Energy Materials and Solar Cells 144, 2016 (109).

J. R. Nicholls, N. J. Simms and A. Encinas-Oropesa, Materials at High Temperatures 24, 2007 (149).

D. Schmidt and M. Schütze, Materials Science Forum 696, 2011 (330).

D. Schmidt, M. Galetz and M. Schütze, Materials at High Temperatures 29, 2012 (159).

P. Huczkowski, Thesis, Universitätsbibliothek, Forschungszentrum Jülich, 2005.

W. J. Quadakkers, J. Piron-Abellan, V. Shemet and L. Singheiser, Materials at High Temperatures 20, 2003 (115).

L. Singheiser, P. Huczkowski, T. Markus and W. J. Quadakkers, in Shreir’s Corrosion, ed. J. A. R. Editor-in-Chief: Tony, (Elsevier, Oxford, 2010), p. 482.

D. Schmidt, M. C. Galetz and M. Schütze, Surface and Coatings Technology 237, 2013 (23).

G. W. Goward, in Proceedings of the Symposium on Properties of High-Temperature Alloys with Emphasis on Environmental Effects, eds. J. K. Tien, and G. S. Ansell, (Academic Press, New York, 1976).

G.Y. Lai, in High Temperature Corrosion and Materials Application, ed. G. Y. Lai, (ASM International, Ohio, 2007), Chap. 11, p. 321.

ISO 21608: International Standard: Corrosion of metals and alloys-Test method for isothermal-exposure oxidation testing under high-temperature corrosion conditions for metallic materials, No. ISO 21608:2012 (2012).

D. Schmidt, M. C. Galetz and M. Schütze, Oxidation of Metals 79, 2013 (589).

ISO 17245: Corrosion of metals and alloys-Test method for high temperature corrosion testing of metallic materials by immersing in molten salt or other liquids under static conditions, No. ISO 17245 (2015).

A. Naji, M. C. Galetz and M. Schütze, Materials and Corrosion 66, 2015 (863).

ThyssenKrupp Materials International Datasheet 1.4903 (P91) (2011).

Y. S. Touloukian, R. K. Kirby, R. E. Taylor and P. D. Desai, Thermal Expansion of Metallic Elements and Alloy, (Plenum Publishing Corporation, New York, 1970).

A. Agüero, R. Muelas, A. Pastor and S. Osgerby, Surface and Coatings Technology 200, 2005 (1219).

A. Agüero and R. Muelas, Materials Science Forum 461–464, 2004 (957).

D. Fähsing, Thesis, RWTH Aachen, SHAKER Verlag, (2016).

R. Prescott and M. J. Graham, Oxidation of Metals 38, 1992 (73).

M. Spiegel and E. Strauch, in Solutions to Corrosion Problems: Proceedings of Eurocorr 1998, (Utrecht, 1998).

Acknowledgements

This work was financially supported by the German Ministry of Economics via IGF-no. 17205N. The authors would like to thank all colleagues from the working group High Temperature Materials at the DECHEMA-Forschungsinstitut for their support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fähsing, D., Rudolphi, M., Konrad, L. et al. Fireside Corrosion of Chromium- and Aluminum-Coated Ferritic–Martensitic Steels. Oxid Met 88, 155–164 (2017). https://doi.org/10.1007/s11085-016-9684-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-016-9684-2