Abstract

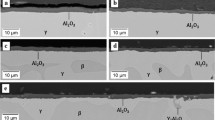

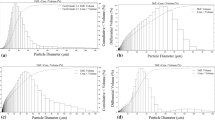

The reaction of cast NiCoCrAlY alloys with oxide–sulfate deposits in CO2–H2O–O2 was studied at 1100 °C. The minimum Al concentration needed to form an external Al2O3 scale was increased compared with deposit-free exposures, as Al2O3-forming compositions transitioned to internal Al2O3 and external Cr2O3 growth in the presence of certain deposits. Model deposits were used to investigate the role of each constituent in the complex reaction morphology observed with an industrial fly-ash. Two main modes of degradation were identified, which involved Al2O3 dissolution in molten Na silicate and solid-state Al2O3 reaction with CaO. Both led to enhanced Al consumption and promoted non-selective oxidation. Additions of Al2O3 or SiO2 decreased the CaO reactivity due to the formation of aluminates or silicates, while Na2SO4, on the contrary, enhanced the degradation by providing rapid mass transport in the molten state, and reduced alloy/scale adherence. A systematic study of the role of phase fractions and phase compositions in the γ-(Ni,Co) + β-(Ni,Co)Al metal system is reported, with the aim of providing guidance in coating design. In particular, high γ fractions and Cr concentrations, which offer optimal hot corrosion resistance, were most susceptible to degradation by oxide–sulfate deposits.

Similar content being viewed by others

References

N. J. Simms, P. J. Kilgallon and J. E. Oakey, Energy Materials 2, 154 (2007).

G. Hammond, S. S. Ondo Akwe and S. Williams, Energy 36, 975 (2011).

B. M. Jenkins, L. L. Baxter, T. R. Miles Jr. and T. R. Miles, Fuel Processing Technology 54, 17 (1998).

C. G. Levi, J. W. Hutchinson, M.-H. Vidal-Setif and C. A. Johnson, MRS Bulletin 37, 932 (2012).

J. P. Bons, J. Crosby, J. E. Wammack, B. I. Bentley and T. H. Fletcher, Journal of Engineering for Gas Turbines and Power 129, 135 (2007).

B.M. White, R.W. Ames and P. Burke, in Proceedings of the ASME Turbo Expo 2013, San Antonio (2013).

Clean Coal Technology Topical Report Number 24, NETL (US Department of Energy, August 2006)

R. C. Reed, The Superalloys—Fundamentals and Applications, (Cambridge University Press, New York, 2006).

S. Bose, High Temperature Coatings, (Butterworth-Heinemann, Amsterdam, 2007).

A. G. Evans, D. R. Mumm, J. W. Hutchinson, G. H. Meier and F. S. Pettit, Progress in Materials Science 46, 505 (2001).

B. Gleeson, Journal of Propulsion and Power 22, 375 (2006).

A. G. Evans, D. R. Clarke and C. G. Levi, Journal of the European Ceramic Society 28, 1405 (2008).

D. R. Clarke, M. Oechsner and N. P. Padture, MRS Bulletin 37, 891 (2012).

R. Darolia, International Materials Reviews 58, 315 (2013).

J. L. Smialek, F. A. Archer and R. G. Garlick, JOM 46, 39 (1994).

M. P. Borom, C. A. Johnson and L. A. Peluso, Surface & Coatings Technology 86, 116 (1996).

C. Mercer, S. Faulhaber, A. G. Evans and R. Darolia, Acta Materialia 53, 1029 (2005).

S. Kramer, J. Yang, C. G. Levi and C. A. Johnson, Journal of the American Ceramic Society 89, 3167 (2006).

J. A. Goebel, F. S. Pettit and G. W. Goward, Metallurgical Transactions 4, 261 (1973).

J. Stringer, Annual Review of Materials Science 7, 477 (1977).

R. Rapp, Corrosion 42, 568 (1986).

G. Goward, Journal of Engineering for Gas Turbines and Power 2, 421 (1986).

N. Birks, G. Meier and F. Pettit, Chapter 8 in Introduction to the High Temperature Oxidation of Metals, 2nd ed, (Cambridge University Press, Cambridge, 2006), pp. 205–252.

F. Pettit, Oxidation of Metals 76, 1 (2011).

T. Gheno, G. H. Meier and B. Gleeson, Oxidation of Metals 84, 185 (2015).

T. Gheno and B. Gleeson, Oxidation of Metals 86, 385 (2016).

T. Gheno and B. Gleeson, Kinetics of Al2O3-scale growth by oxidation and dissolution in molten silicate, submitted to Oxidation of Metals.

Materials Preparation Center, Ames Laboratory USDOE, Ames, IA.

Evans Analytical Group, Liverpool, NY.

U.R. Kattner, in Calphad and alloy thermodynamics, TMS, Warrendale, 2002

B. Sundman, B. Jansson and J.-O. Andersson, Calphad 9, 153 (1985).

T. Gheno, X. L. Liu, G. Lindwall, Z. K. Liu and B. Gleeson, Science and Technology of Advanced Materials 16, 055001 (2015).

X. L. Liu, G. Lindwall, T. Gheno and Z. K. Liu, Calphad 52, 125 (2016).

V. K. Tolpygo and D. R. Clarke, Materials at High Temperatures 17, 59 (2000).

FToxid 2010 database from FactSage, phase diagram retrieved on http://www.crct.polymtl.ca/fact/documentation/, October 14, 2015

C. S. Giggins and F. S. Pettit, Journal of the Electrochemical Society 118, 1782 (1971).

T. Gheno, B.-C. Zhou, A. Ross, X. Liu, G. Lindwall, Z.-K. Liu, B. Gleeson, A thermodynamic approach to guide reactive element doping: Hf additions to NiCrAl, submitted to Oxidation of Metals

M. N. Task, B. Gleeson, F. S. Pettit and G. H. Meier, Oxidation of Metals 80, 125 (2013).

A. Chyrkin, W. G. Sloof, R. Pillai, T. Galiullin, D. Gruener, L. Singheiser and W. J. Quadakkers, Materials at High Temperatures 32, 102 (2015).

M. Schiek, L. Niewolak, W. Nowak, G. H. Meier, R. Vaßen and W. J. Quadakkers, Oxidation of Metals 84, 661 (2015).

I. Barin, Thermochemical Data of Pure Substances, 2nd ed, (VCH, Weinheim, 1993).

D. Freyer and W. Voigt, Monatshefte für Chemie 134, 693 (2003).

P. D. Jose, D. K. Gupta and R. A. Rapp, Journal of the Electrochemical Society 132, 735 (1985).

M. G. Lawson, F. S. Pettit and J. R. Blachere, Journal of Materials Research 8, 1964 (1993).

J. G. Smeggil, A. W. Funkenbusch and N. S. Bornstein, Metallurgical Transactions A 17, 923 (1986).

J. L. Smialek, D. T. Jayne, J. C. Schaeffer and W. H. Murphy, Thin Solid Films 253, 285 (1994).

P. Y. Hou and J. Stringer, Oxidation of Metals 38, 323 (1992).

E. M. Levin, C. R. Robbins and H. F. McMurdie (eds.), Phase Diagrams for Ceramists, vol. I, (The American Ceramic Society, Columbus, 1964).

R. Melzer and W. Depmeier, Crystal Research and Technology 31, 459 (1996).

S. M. Antao, I. Hassan and J. B. Parise, The Canadian Mineralogist 42, 1047 (2004).

Acknowledgements

This work was supported by the Department of Energy through the University Turbine Systems Research (UTSR) Program run by the National Energy Technology Laboratory, award number DE-FE0007271, Seth Lawson, Project Manager. The authors thank Morgan Skapik and Kevin Glorius-Patrick for assistance in preparing the corrosion experiments, Gerald Meier and Nathaniel Bohna for useful discussions, and Xuan Liu and Zi-Kui Liu at the Pennsylvania State University for the phase equilibrium calculations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gheno, T., Gleeson, B. Modes of Deposit-Induced Accelerated Attack of MCrAlY Systems at 1100 °C. Oxid Met 87, 249–270 (2017). https://doi.org/10.1007/s11085-016-9669-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-016-9669-1