Abstract

Ytterbium-doped optical amplifiers have become common tools for industrial applications due to their high efficiency, relatively low cost and potentially very high output power level. The efficiency of an ytterbium-doped fiber amplifier depends mainly on the absorption of pump radiation, and, therefore, optimum pump wavelengths have been proposed such as 915 nm. However, the semiconductor pump diodes batch supplied by manufacturers may exhibit a spread in the output wavelength. This paper theoretically investigates the performance of Yb-doped amplifiers for different pump wavelengths and defines the pump power penalty when the pump source does not emit at the optimum wavelength. The penalty has been defined as normalized excess pump power required to achieve the desired gain.

Similar content being viewed by others

1 Introduction

Ytterbium-doped fibre amplifiers (YDFA) provide a wide gain bandwidth, high output power, and a high electrical to optical power conversion efficiency, making them suitable for medium and high power applications (Paschotta et al. 1997; Zervas 2014; Injeyan and Goodno 2011). This makes YDFAs one of the most common type of amplifiers in numerous applications, ranging from medium to high-power amplification, such as mass, manufacturing, fiber sensing, free-space laser communication, and ultra-short pulse amplification (Paschotta et al. 1997; Pask et al. 1995; O’Neill 2008; Zhang et al. 2012a, b; Zervas 2014; Nogee 2014). In case of device low price target for large market production there is a sensitive economic-engineering issue related to supplied pump diodes. In fact the semiconductor pump lasers are usually supplied, to reduce cost, without a specific wavelength, and therefore the supplied batch may exhibit a significant wavelength spread. The non-optimum pump diode wavelength implies need of driving the diode with higher current intensity to achieve the desired gain and this turns out into higher running costs as well accelerated diode aging. The aim of this paper is to numerically explore the impact of the diode pump wavelength on the amplifier efficiency and provide guidelines on tolerated pump diode wavelength spread. Laser numerical simulations, are in fact a useful tool to predict general device behaviour since the era of telecom Erbium-doped fiber amplifiers and have now reached a high degree of sophistication (D’Orazio et al. 2005; Giles and Desurvire 1991; He et al. 2006; Magne et al. 1994).

The configuration that will be analyzed is one of the more common in laser industry, in term of mass use, being used, for example, for marking processes, and is based on the Master-Oscillator-Power-Amplifier (MOPA) scheme where the YDFA is seeded by a few hundred of mW input and provide an output power of about 20 W (O’Neill 2008; Zhang et al. 2012a; Pask et al. 1995; Snitzer 1966). We will evaluate the extra pump power required to achieve a desired gain in case of non-optimal pump diode wavelength. We will consider amplification of both 1030 and 1064 nm signals.

2 Simulation

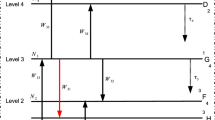

We investigated a 20 W, 17 dB gain (i.e. with a 0.4 W seed) Yb-doped germane-silicate continuous wave amplifier (Paschotta et al. 1997; Zervas 2014; Zhang et al. 2012a; Pask et al. 1995; O’Neill 2008), being a quite common design for the large market of lasers for marking. The doping level was set to be compatible with a fiber length ranging from 3 to 13 m. We simulated the device under continuous wave condition since results may be extended in term of efficiency to a configuration were a ns pulsed seed is used (O’Neill 2008). Of course, in case of long fiber lengths, the amplifier pulsed amplification will suffer from several nonlinear effects, here not considered. This was also the reason to use maximum length of 13 m above which nonlinear effects may be detrimental. The specifications of the active fiber are summarized in Table 1. The active fiber is a Yb-doped germanium silicate fiber, doping concentration, N yb , is 3 × 1025 m−3, and input signal power P s is 400 mW with a targeted 17 dB gain. The absorption and emission cross-sections for Yb-doped germanium silicate glass fiber by Paschotta et al. (1997) are shown in Fig. 1 (Paschotta et al. 1997; O’Connor and Shiner 2011; Weber et al. 1983), and commercial software (RP Fiber Power) was used for the simulation (Paschotta 2011). In the simulation, we used the standard ytterbium two level scheme and we included the impact of amplified spontaneous emission (ASE) using emission and absorption cross section data of Fig. 1 (Paschotta 2011). No phenomena, as photodarkening, depending on the local inversion level, have been considered, yet, for the given configuration they should not impact the comparison we investigate (Taccheo et al. 2011; Gebavi et al. 2015). The fiber radius was set at r = 5 µm, while the length of the fiber has been varied from 3 to 13 m. A Gaussian field distribution of 4.8 um radius was used for the propagation of signal radiation, while the pump radius is set at 50 µm, with a top-hat profile to simulate a double cladding fiber with a 100 µm diameter outer cladding.

Absorption and emission cross-section of ytterbium-doped germanosilicate glass (Paschotta et al. 1997)

The used software (Paschotta 2011) utilizes the Finite Difference Time Domain with a fixed number of mesh points, N, which the software employs to solve the differential equations. In order to avoid gain calculation errors we performed a preliminary set of simulation, showing gain calculations reaches a stable value for N > 50, a safeguard value of 1000 was chosen.

3 Results and discussion

3.1 Pump power for seed wavelength of 1030 and 1064 nm

Figure 2a shows the required pump power versus fiber length and pump wavelength with a 1030 nm seed. We notice that for a 3 m fiber length, the minimum pump power is 47,2 W at 914 nm and then increases as the pump diode wavelength diverges from optimum value to reach 60.5 W at 930 nm, and 64.7 W at 890 nm as shown in Fig. 2b. As the fiber length increases the optimum wavelength red-shift and the minimum pump power decreases as well as the difference between minimum pump power and the power at the edges: 26.5 W at 890 nm wavelength, 23.8 W at 918 nm wavelength (minimum) and 25.3 W at 930 nm wavelength. However we notice that pulsed amplification in case of long fibre will be limited by non-linear effects (Paschotta et al. 1997; Zervas 2014; Pask et al. 1995), so long fibre case may not be practical for pulsed amplification.

Figure 3 illustrates the same simulations for a 1064 nm seed. While the absolute power is a slightly different from the case of the 1030 nm wavelength seed of Fig. 2a, the difference between optimum case and edge pump wavelength excess power is very similar. For example in case of the fiber length of 3 m, minimum pump power is 50.4 W at wavelength of 914 nm, and reaches 69.3 W at 890 nm wavelength.

3.2 Normalized pump power penalty

Since each specific amplifier may require a different pump power level, we decided to define a normalized power penalty as excess pump power percentage required to reach the desired gain, 17 dB in our case. The normalized pump power penalty (P n ) is defined as:

where P pw (λ, L) is the pump power at a given fiber length, L, and for a specific pump wavelength λ, and P opt (λ min , L) is the minimum pump power required at the optimum wavelength λ min and for the same fiber length L.

Figure 4a illustrates that normalized excess pump power using data from Fig. 2. Note for sake of clarity we shows on the right side (Fig. 4b) the same data in a bidimensional plot. Here we notice more clearly that short fibre lengths are definitively far more sensitive to diode pump wavelength spread: up to 37.2 % normalized pump power penalty is reached in case of using a 890 nm pump laser diodes in a 3 m long amplifier, while normalized pump power penalty is 12.5 % at 890 nm for a 13 m fibre length.

Similar results and behaviours are obtained when the signal wavelength is set at 1064 nm as shown in Fig. 5.

Considering Figs. 4 and 5 we notice that power penalty is very similar and therefore some guidelines can be drawn. As example if we set a 10 % normalized pump power penalty the allowed batch wavelength spread is between 901 and 924 nm for short fibre. We also note that penalty grows non linearly with the wavelength offset and varies from 10 % to over 25 % when moving from 898 to 890 nm pump wavelength. Results also indicates the laser performance will be more sensitive with respect pump wavelength offset if short fibre lengths are planned to be used, as in the case of short amplifiers for short pulse amplification.

4 Conclusion

This paper shows pump diode wavelength spread may cause an increase in the required pump power, thus increasing the diode driver current and likely accelerating pump diode ageing. The paper proposes a simple model to quantify the pump power penalty associate to the use of non optimum wavelength pump laser diode. This allows to define the tolerable pump wavelength spread. As general guideline pump power penalty is higher for shorter fibers, preferred to reduce nonlinear phenomena, and the penalty is more severe for pump wavelength red shifted with respect the optimum pump wavelength. As example a maximum of 10 % penalty is achieved within a −13/+10 nm interval with respect to the optimum pump wavelength of 914 nm for a 3 m long fiber. In case of highly doped amplifiers schemes using very short fibre the system will be even more sensitive.

References

D’Orazio, A., De Sario, M., Mescia, L., Petruzzelli, V., Prudenzano, F.: Design of double-clad ytterbium-doped microstructured fibre laser. Appl. Surf. Sci. 248(1), 499–502 (2005)

Gebavi, H., Chiasera, A., Ferrari, M., Mechin, D., Robin, T., Taccheo, S.: Comparison of photodarkening in 1030 nm and 1070 nm Yb-doped fibre lasers. In: SPIE OPTO, pp. 935912-935912. International Society for Optics and Photonics (2015)

Giles, C.R., Desurvire, E.: Modeling erbium-doped fiber amplifiers. J. Lightwave Technol. 9(2), 271–283 (1991)

He, F., Price, J.H.V., Vu, K.T., Malinowski, A., Sahu, J.K., Richardson, D.J.: Optimisation of cascaded Yb fiber amplifier chains using numerical-modelling. Opt. Express 14(26), 12846–12858 (2006)

Injeyan, H., Goodno, G.: High Power Laser Handbook. McGraw Hill Professional, New York (2011)

Magne, S., Druetta, M., Goure, J.-P., Thevenin, J.C., Ferdinand, P., Monnom, G.: An ytterbium-doped monomode fiber laser: amplified spontaneous emission, modeling of the gain and tunability in an external cavity. J. Lumin. 60, 647–650 (1994)

Nogee, A.: The worldwide market for lasers-market review and forecast 2014. Strateg. Unltd., 32 (2014)

O’Neill, W.: MOPA-based fibre lasers offer processing options. Opt. Laser Eur., 17–19 (2008)

O’Connor, M., Shiner, B.: High power fiber lasers for industry and defense. In: High power laser handbook, chap. 18, pp. 517–532 (2011)

Paschotta, R.: Ytterbium-doped gain media. Encyclopedia of laser physics and technology (2011)

Paschotta, R., Nilsson, J., Tropper, A.C., Hanna, D.C.: Ytterbium-doped fibre amplifiers. IEEE J. Quantum Electron. 33(7), 1049–1056 (1997)

Pask, H.M., Carman, R.J., Hanna, D.C., Tropper, A.C., Mackechnie, C.J., Barber, P.R., Dawes, J.M.: Ytterbium-doped silica fiber lasers: versatile sources for the 1–1.2 μm region. IEEE J. Sel. Top. Quantum Electron. 1(1), 2–13 (1995)

Snitzer, E.: Glass lasers. Appl. Opt. 5(10), 1487–1499 (1966)

Taccheo, S., Gebavi, H., Monteville, A., Le Goffic, O., Landais, D., Mechin, D., Tregoat, D., Cadier, B., Robin, T., Milanese, D., Durrant, T.: Concentration dependence and self-similarity of photodarkening losses induced in Yb-doped fibers by comparable excitation. Opt. Express 19(20), 19340–19345 (2011)

Weber, M.J., Lynch, J.E., Blackburn, D.H., Cronin, D.J.: Dependence of the stimulated emission cross section of Yb3+ on host glass composition. IEEE J. Quantum Electron. 19(10), 1600–1608 (1983)

Zervas, M.N.: High power ytterbium-doped fiber lasers—fundamentals and applications. Int. J. Mod. Phys. B 28(12), 1442009 (2014)

Zhang, H.T., Zheng, C., Yan, P., Gong, M.L., Xiao, Q.R., Zhao, Q.: 13.9-mJ all fiber wide band ytterbium-doped fiber amplifier. Laser Phys. Lett. 9(10), 744 (2012a)

Zhang, L., Wang, Y.G., Yu, H.J., Sun, W., Yang, Y.Y., Han, Z.H., Qu, Y., Hou, W., Li, J.M., Lin, X.C.: 20 W high-power picosecond single-walled carbon nanotube based MOPA laser system. J. Lightwave Technol. 30(16), 2713–2717 (2012b)

Acknowledgments

Ali Albalawi acknowledges support of Cultural Bureau in London (UKSACB). This article is based upon work from COST Action MP1401 supported by COST “(European Cooperation in Science and Technology)”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Albalawi, A., Zhu, H., Taccheo, S. et al. Numerical modeling of the impact of pump wavelength on Yb-doped fiber amplifier performance. Opt Quant Electron 48, 500 (2016). https://doi.org/10.1007/s11082-016-0771-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-016-0771-z