Abstract

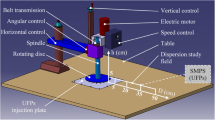

Nanometer particle size distributions were measured in booths with two different ventilation patterns in an occupational environment with welding operations underway. The measurements were used to illustrate the impact of change of ventilation methods (existing – with ventilation ducts located at the top, modified – with ventilation ducts located below the weld bench) on the aerosol size distributions at different locations: close to the weld, in the vicinity of the welder’s face, and in the exhaust duct. Particle number concentrations measured in the vicinity of the welder’s face (mask) during a horizontal standard arc welding process in a booth with ventilation at the top was in the range of 7.78×105 particles cm−3 with a geometric mean size of 181 nm and geometric standard deviation of 1.8. This reduced to 1.48×104 particles cm−3 in the vicinity of the welder’s face with the modified ventilation system. The clearance of the welding aerosol was also faster in the modified booth (6 min compared to 11 min in a conventional booth). Particles were collected in the booth for the various test conditions, and analyzed to determine their composition and morphology. The particles were composed of hazardous heavy metals such as manganese, chromium and nickel, and had varying morphologies.

Similar content being viewed by others

References

AFSCME, 2004. Welding hazards. http://www.afscme.org/health/faq-weld.htm

ACGIH, 1994. Threshold limit values for chemical substances and physical agents and biological exposure indices, Cincinnati, OH. American Conference of Governmental Industrial Hygienists

Antonini J.M., Lewis A.B., Roberts J.R., Whaley D.A., 2003. Pulmonary effects of welding fumes: Review of worker and experimental animal studies Am. J. Ind. Med. 43(4):350–360

Biswas P., Yang G., Zachariah M.R., 1998. In situ processing of ferroelectric materials from lead waste streams by injection of gas phase titanium precursors: Laser induced fluorescence and X-ray diffraction measurements Combust. Sci. Technol. 134(1–6):183–200

Biswas P., Wu C.Y., 2005. Nanoparticles and the environment: A critical review paper J. Air Waste Manage. Assoc. 55:708–746

Konarski P., Iwanejko I., Cwil M., 2003. Core-shell morphology of welding fume micro- and nanoparticles Vacuum 70(2–3):385–389

Kuo Y.M., Huang S.H., Shih T.S., Chen C.C., Weng Y.M., Lin W.Y., 2005. Development of a size-selective inlet-simulating ICRP lung deposition fraction Aerosol Sci. Technol. 39(5):437–443

McNeilly J.D., Heal M.R., Beverland I.J., Howe A., Gibson M.D., Hibbs l.R., MacNee W., Donaldson K., 2004. Soluble transition metals cause the pro-inflammatory effects of welding fumes in vitro Toxicol. Appl. Pharmacol. 196(1):95–107

NIOSH, 1988. NIOSH Criteria for a Recommended Standard: Welding, brazing, and Thermal Cutting. DHHS (NIOSH) publication No. 88–110, Cincinnati, OH

Savage N., Diallo M.S., 2005. Nanomaterials and water purification: Opportunities and challenges J. Nanoparticle Res. 7(4–5):331–342

Sjogren B., Hansen K.S., Kjuus H., Persson P.G., 1994. Exposure to stainless-steel welding fumes and lung-cancer – a metaanalysis Occup. Environ. Med. 51(5):335–336

Stephenson D., Seshadri G., Veranth J.M., 2003. Workplace exposure to submicron particle mass and number concentrations from manual arc welding of carbon steel AIHA J. 64(4):516–521

Stern R.M., 1983. Assessment of risk of lung cancer for welders Arch. Environ. Health 38:148–155

Vincent J.H., Clement C.F., 2000. Ultrafine particles in workplace atmospheres. Phil. Trans. Royal Soc. London A Mathematical Phys. Eng. Sci. 358(1775):2673–2682

Zimmer A.T., Baron P.A., Biswas P., 2002. The influence of operational parameters on number-weighted aerosol size distribution generated from a gas metal arc welding process J. Aerosol Sci. 33:519–531

Zimmer A.T., Biswas P., 2001. Characterization of the aerosols resulting from arc welding processes J. Aerosol Sci. 32: 993–1008

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, MH., McClellan, W.J., Candela, J. et al. Reduction of nanoparticle exposure to welding aerosols by modification of the ventilation system in a workplace. J Nanopart Res 9, 127–136 (2007). https://doi.org/10.1007/s11051-006-9181-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11051-006-9181-7