Abstract

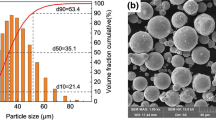

In this study, Ti-27Ni-19Nb-4Ta and Ti-27Ni-19Nb-4 V (at./%) alloys were produced by arc-melting alloyed. The thermal properties of alloys were investigated by differential scanning calorimeter (DSC). The DSC results showed that the phase transformation temperatures of the Ta-added alloy were significantly higher than the V-added sample. Also, the Ta-added sample showed B19/ → R → B2 phase transformation, while the V-added sample exhibited B19/ → B2 phase transformation in two steps. When TiNiNbTa and TiNiNbV SMAs are compared, it is seen that the Ta-added sample exhibits a better corrosion resistance. In addition, β-Nb phase was found in the dendritic structures of the alloys in scanning electron microscopy-energy-dispersive X-ray spectroscopy(SEM–EDX) analysis. Using the X-ray diffraction(XRD) results, the crystallite size for TiNiNbTa and TiNiNbV samples was found as 33.76 and 46.86 nm, respectively. It was determined that the microhardness of the V-added alloy was much higher than the Ta-added alloy.

Similar content being viewed by others

References

Sui JH, Gao ZY, Li YF, Zhang ZG, Cai W. A study on NiTiNbCo shape memory alloy. Mater Sci Eng A. 2009;508(1):33–6. https://doi.org/10.1016/j.msea.2009.01.018.

Piao M, Miyazaki S, Otsuka K. Characteristics of deformation and transformation in Ti44Ni47Nb9 shape memory alloy. Mater Trans JIM. 1992;33(4):346–53. https://doi.org/10.2320/matertrans1989.33.346.

Zhang CS, Zhao LC, Duerig TW, Wayman CM. Effects of deformation on the transformation hysteresis and shape memory effect in a Ni47Ti44Nb9 alloy. ScMM. 1990;24(9):1807–12. https://doi.org/10.1016/0956-716X(90)90550-Z.

Zhang CS, Wang YQ, Chai W, Zhao LC. The study of constitutional phases in a Ni47Ti44Nb9 shape memory alloy. Mater Chem Phys. 1991;28(1):43–50. https://doi.org/10.1016/0254-0584(91)90051-U.

He XM, Rong LJ, Yan DS, Li YY. Temperature memory effect of Ni47Ti44Nb9 wide hysteresis shape memory alloy. Scripta Mater. 2005;53(12):1411–5. https://doi.org/10.1016/j.scriptamat.2005.08.022.

Oshida Y. Bioscience and bioengineering of titanium materials. Elsevier; 2010.

Dagdelen F, Aydogdu Y. Transformation behavior in NiTi–20Ta and NiTi–20Nb SMAs. J Therm Anal Calorim. 2019;136(2):637–42. https://doi.org/10.1007/s10973-018-7635-7.

Wei L, Xinqing Z. Mechanical properties and transformation behavior of NiTiNb shape memory alloys. Chin J Aeronaut. 2009;22(5):540–3. https://doi.org/10.1016/S1000-9361(08)60138-7.

Wataha JC. Biocompatibility of dental casting alloys: a review. J Prosthet Dent. 2000;83(2):223–34. https://doi.org/10.1016/S0022-3913(00)80016-5.

Mareci D, Chelariu R, Cailean A, Sutiman D. Electrochemical characterization of Ni47. 7Ti37. 8Nb14. 5 shape memory alloy in artificial saliva. Mater Corros. 2012;63(9):807–12. https://doi.org/10.1002/maco.201106337.

Köster R, Vieluf D, Kiehn M, Kähler J, Hamm CW. Allergy in coronary in-stent restenosis. The Lancet. 2001;357(9263):1206–7. https://doi.org/10.1016/S0140-6736(00)04353-1.

Ryhänen J, Niemi E, Serlo W, Niemelä E, Sandvik P, Pernu H, et al. Biocompatibility of nickel-titanium shape memory metal and its corrosion behavior in human cell cultures. J Biomed Mater Res. 1997;35(4):451–7. https://doi.org/10.1002/(SICI)1097-4636(19970615)35:4%3c451::AID-JBM5%3e3.0.CO;2-G.

Lee J, Park J, Andreasen G, Lakes R. Thermomechanical study of Ni-Ti alloys. J Biomed Mater Res. 1988;22(6):573–88. https://doi.org/10.1002/jbm.820220611.

Dagdelen F, Balci E, Qader IN, Ozen E, Kok M, Kanca MS, et al. Influence of the Nb content on the microstructure and phase transformation properties of NiTiNb shape memory alloys. JOM. 2020;72(4):1664–72. https://doi.org/10.1007/s11837-020-04026-6.

Kök M, Al-Jaf AOA, Çirak ZD, Qader IN, Özen E. Effects of heat treatment temperatures on phase transformation, thermodynamical parameters, crystal microstructure, and electrical resistivity of NiTiV shape memory alloy. J Therm Anal Calorim. 2020;139(6):3405–13. https://doi.org/10.1007/s10973-019-08788-3.

Dagdelen F, Kok M, Qader IN. Effects of Ta content on thermodynamic properties and transformation temperatures of shape memory NiTi alloy. Met Mater Int. 2019;25(6):1420–7. https://doi.org/10.1007/s12540-019-00298-z.

Bao Z-Z, Shun G, Fu X, Zhao X-Q. Development of NiTiNb in-situ composite with high damping capacity and high yield strength. Progress Nat Sci Mater Int. 2011;21(4):293–300. https://doi.org/10.1016/S1002-0071(12)60060-4.

Lohan N, Pricop B, Popa M, Matcovschi E, Cimpoeşu N, Cimpoeşu R, et al. Hot rolling effects on the microstructure and chemical properties of NiTiTa alloys. J Mater Eng Perform. 2019;28(12):7273–80. https://doi.org/10.1007/s11665-019-04473-6.

Balci E, Dagdelen F, Qader IN, Kok M. Effects of substituting Nb with V on thermal analysis and biocompatibility assessment of quaternary NiTiNbV SMA. Eur Phys J Plus. 2021;136(2):1–13. https://doi.org/10.1140/epjp/s13360-021-01149-w.

Ying C, Hai-Chang J, Li-Jian R, Li X, Xin-Qing Z. Mechanical behavior in NiTiNb shape memory alloys with low Nb content. Intermetallics. 2011;19(2):217–20. https://doi.org/10.1016/j.intermet.2010.08.011.

Qader IN, Kok M, Cirak ZD. The effects of substituting Sn for Ni on the thermal and some other characteristics of NiTiSn shape memory alloys. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09758-w.

Tatar C, Acar R, Qader IN. Investigation of thermodynamic and microstructural characteristics of NiTiCu shape memory alloys produced by arc-melting method. Eur Phys J Plus. 2020;135(3):311. https://doi.org/10.1140/epjp/s13360-020-00288-w.

Qader IN, Öner E, Kok M, Mohammed SS, Dağdelen F, Kanca MS, et al. Mechanical and thermal behavior of Cu84−xAl13Ni3Hfx shape memory alloys. Iran J Sci Technol A. 2020. https://doi.org/10.1007/s40995-020-01008-w.

Velmurugan C, Senthilkumar V. The effect of Cu addition on the morphological, structural and mechanical characteristics of nanocrystalline NiTi shape memory alloys. J Alloys Compounds. 2018;767:944–54.

Olumi S, Sadrnezhaad S, Atai M. The influence of surface nanocrystallization induced by shot peening on corrosion behavior of NiTi Alloy. J Mater Eng Perform. 2015;24(8):3093–9. https://doi.org/10.1007/s11665-015-1570-6.

Zhao Y, Jiang C, Xu Z, Cai F, Zhang Z, Fu P. Microstructure and corrosion behavior of Ti nanoparticles reinforced Ni–Ti composite coatings by electrodeposition. Mater Des. 2015;85:39–46. https://doi.org/10.1016/j.matdes.2015.06.144.

Hoseini M, Shahryari A, Omanovic S, Szpunar JA. Comparative effect of grain size and texture on the corrosion behaviour of commercially pure titanium processed by equal channel angular pressing. Corros Sci. 2009;51(12):3064–7. https://doi.org/10.1016/j.corsci.2009.08.017.

Hwang DY, Cho JY, Lee DH, Yoo BY, Shin DH. Plasma electrolytic oxidation of AZ91 Mg alloy in the sodium stannate electrolyte. Mater Trans. 2008:0806020436. doi.org/https://doi.org/10.2320/matertrans.MC200797.

Muthukumaran V, Selladurai V, Nandhakumar S, Senthilkumar M. Experimental investigation on corrosion and hardness of ion implanted AISI 316L stainless steel. Mater Des. 2010;31(6):2813–7. https://doi.org/10.1016/j.matdes.2010.01.007.

Hussein AH, Gepreel MA-H, Gouda MK, Hefnawy AM, Kandil SH. Biocompatibility of new Ti–Nb–Ta base alloys. Mater Sci Eng C. 2016;61:574–8. https://doi.org/10.1016/j.msec.2015.12.071.

Vasilescu E, Drob P, Raducanu D, Cinca I, Mareci D, Moreno JC, et al. Effect of thermo-mechanical processing on the corrosion resistance of Ti6Al4V alloys in biofluids. Corros Sci. 2009;51(12):2885–96. https://doi.org/10.1016/j.corsci.2009.08.014.

Zhou YL, Niinomi M, Akahori T, Fukui H, Toda H. Corrosion resistance and biocompatibility of Ti–Ta alloys for biomedical applications. Mater Sci Eng A. 2005;398(1–2):28–36. https://doi.org/10.1016/j.msea.2005.03.032.

Karlík M, Haušild P, Beran P, Novák P, Čapek J, Kučera V, Kopeček J, Phase Evolution in Ni–48at.% Ti Shape Memory Alloy prepared by Self-Propagating High-Temperature Synthesis. Metal, 2015.

Author information

Authors and Affiliations

Contributions

The authors state that there is no conflict of interest in the printing of this manuscript. The authors have an equal contribution.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Balci, E., Dagdelen, F. The comparison of TiNiNbTa and TiNiNbV SMAs in terms of corrosion behavior, microhardness, thermal and structural properties. J Therm Anal Calorim 147, 10943–10949 (2022). https://doi.org/10.1007/s10973-022-11360-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11360-1