Abstract

This paper deals with the recognition of selected burning liquids by convolutional neural networks (CNNs). Three CNNs (AlexNet, GoogLeNet and ResNet-50) were trained, validated and tested (in the MATLAB 2020b software) for the recognition of selected liquids (ethanol, propanol and pentane) using photographs of the flames they produce. For training, validation and test photographs of the liquids under investigation burning in a 106-mm-diameter vessel were used. The accuracy of all the CNNs under investigation during the tests was above 99%. In addition the trained CNNs were tested using photographs of the flames generated by the liquids under investigation burning in a vessel with a diameter of 75 mm. The accuracy of the trained CNNs in this additional test ranged from 37 to 42% (GoogLeNet) through 62–73% (ResNet-50) up to 51–80% (AlexNet) – the results varied dependent upon the relative size of the flame in the photograph under analysis (in most cases an increase in the relative size caused an increase in accuracy). The accuracy of the AlexNet can be improved from 80% to almost 96% using an algorithm. The principle of the algorithm is the analysis of 10 photographs of the same liquid in the same vessel (taken over a few seconds) followed by the recognition based on an identical classification for at least 6 out of 10 photographs. An accuracy of 96% is sufficient for the rapid recognition of burning liquids in practical applications.

Similar content being viewed by others

Introduction

Contactless, rapid and accurate identification of a burning substance has numerous important applications. The first is the identification of a burning substance to allow the selection of a safe and effective extinguishing agent, as the selection of an inappropriate combination (of a burning substance and an extinguishing agent) may cause a range of negative effects ranging from a failure to extinguish the fire to a dangerous chemical reaction. Second, it can be used to search for the cause of a fire, as the rapid identification of a burning substance is often fundamental to the accurate identification of the cause of a fire. The third application is in the control of combustion processes (especially) in industry.

A burning substance can be identified using several methods. The most common method of identification is through the use of hazard symbols (such as ADR signs, Kemler Code, UN Code and NFPA Danger Classification Diamond). These hazard symbols have a disadvantage—flammable substances are not always labelled with them. An even greater disadvantage is the possibility that the labels are incorrect which leads to the risk of incorrect identification. Another approach to the identification of substances uses chemical analysis (e.g. chromatography in combination with mass spectroscopy). A detailed overview of the methods used for chemical analysis (also suitable for the identification of burning substances) is provided by, for example, Danzer [1]. All the methods described by Danzer [1] require that a sample be taken for analysis. The disadvantage of these methods is that none of them enables the rapid identification of a burning substance (in the order of seconds), contact free (at an order of distance greater than the diameter of the fire) and at the same time using cost-effective technical equipment that can be used outdoors and under demanding industrial conditions.

Similarly, the identification of the presence of specific flammable substances (at the source of a fire) when searching for the causes of the fire may be performed using numerous analytical methods, as described by, for example, Stauffer et al. [2]. A typical example is the extraction of residues of a flammable liquid from solid residues after a fire and the subsequent chromatographic analysis in combination with mass spectrometry. The disadvantage of both of these methods is that generally samples need to be taken at the source of the fire, and the results are only available after several hours or days. Immediate information on the presence of specific flammable substances (especially those used as fire accelerants, such as petrol) at the source of the fire would be of substantial value in the search for the causes of the fire.

The control of combustion processes in industry is mainly performed on the basis of the amount and type of fuel and the regulation of the amount of primary and secondary air supplied to the combustion plant (a boiler). Fuel composition control is performed before the fuel input to the combustion plant. However, a rapid, contactless method for the identification of a burning substance (fuel) would be also applicable as an additional simple method for combustion process control.

Over the last decade, artificial neural networks (e.g. Mei et al. [3] and Wu et al. [4]) and advanced methods of mathematical statistics (e.g. Xu et al. [5]) have been used extensively in data analysis and to predict the properties of substances and materials. Convolutional neural networks (CNNs) are used in the analysis of images, sounds, texts or, in general, signals. CNNs are able to recognise those objects that they have been trained to recognise in images or video sequences (e.g. cars, bicycles, cats, dogs, flowers, etc.). Very interestingly, CNNs are used to recognise pathological changes in medical images (e.g. in computed tomography images), currently they are specifically used in the presumptive diagnosis of SARS-CoV-2 (Covid-19) from an X-ray image of the lungs.

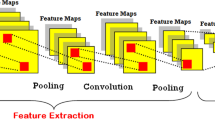

Today, there are numerous CNNs, with differing architecture (number, type, order and interconnection of layers). CNNs are generally composed of the following layers: a convolutional layer, a nonlinear activation function (most frequently a rectifier linear unit), pooling, fully connected and a classification layer. A detailed description of CNNs can be found in Mou and Jin [6], Aghdam and Heravi [7], Lu et al. [8] and Aggarwal [9].

CNNs are also commonly used to detect fires. Fire detection is solved as a classification task by CNNs. These CNNs classify images or video sequences into two (no fire and fire) or three classes (no fire, pre-alarm and fire). According to Li and Zhao [10], a very important part of the algorithm used for fire detection by CNNs is the regional proposal (responsible for the selection of a part of the image of a fire or smoke for a detailed analysis). In the opinion of these authors [10], this algorithm runs in the convolutional and pooling layers. The selection of a particular CNN architecture is specific to the task that the neuronal network is intended to solve.

A relatively large number of CNNs is used for fire detection. AlexNet, GoogLeNet and Residual Neural Network (ResNet-50) are among the most prevalent. Selected CNNs for fire detection were trained and their accuracy investigated by Hu and Lu [11], Namozov and Cho [12], Mao et al. [13], Muhammad et al. [14], Tao et al. [15] and Yin et al. [16]. However, no scientific study has considered the potential application of CNNs to the identification of a burning substance (and their accuracy) from a photograph of its flame.

This scientific study aims to verify if the aforementioned CNNs (AlexNet, GoogLeNet and ResNet-50) can be used to identify a burning substance and compare the accuracy of the different CNNs under laboratory conditions. The CNNs under investigation will be trained and their accuracy validated and tested in the recognition of three types of burning liquid: ethanol, propan-1-ol (hereinafter only as propanol) and pentane. Ethanol, propanol and pentane were selected in order to verify the accuracy of the CNNs under investigation in the recognition of burning liquids with very similar fire characteristics (ethanol and propanol are primary alcohols adjacent in the homologous series) and burning liquid with a significantly different fire characteristic (pentane is a liquid alkane with the shortest chain). The objective of the study is to verify whether the CNNs can be trained to recognise these flammable liquids (even if the flammable liquids have very similar characteristics) with a high degree of accuracy (over 95%), to establish the recognition limits and to verify whether there is a difference in accuracy in the recognition of flammable liquids with very similar characteristics versus flammable liquids with significantly different fire characteristics.

Material and methods

Three CNNs, AlexNet, GoogLeNet and ResNet-50 were used in the recognition of flammable substances. These CNNs are accessible through the MATLAB 2020b software, which was used to modify, train, validate and test them. The basic parameters of the CNNs under investigation are presented in Table 1. The Deep Network Designer application (part of MATLAB) enables a comprehensive representation of the architecture of the CNNs (parameters and interconnection of layers) as well as their modification. The modification of all the CNNs consisted of an adaptation of the last fully connected layer (AlexNet: 23th layer, GoogLeNet: 142th layer and ResNet-50: 175th layer) and the last output layer (AlexNet: 25th layer, GoogLeNet: 144th layer and ResNet-50: 177th layer) from output size 1000 to output size 3. This adaptation was made as the CNNs under investigation are commonly used to recognise up to 1000 different objects, while in this study they are only required to recognise three types of burning substances. The training options for the CNNs: Stochastic Gradient Descent with Momentum (SGDM) and an initial learning rate: 0.001.

The training, validation and testing of the CNNs were performed using an HP EliteBook 8570p laptop (processor Intel® Core™ i5-3320 M CPU (4CPUs) 2.60 GHz, RAM 8.00 GB, dedicated graphics card AMD Radeon HD7570M, operating system Windows 10 PRO, 64-bit, version 1909).

Centralchem, s.r.o. (Bratislava, Slovakia) supplied ethanol, propanol and pentane, which were used as samples of flammable liquids. The basic properties of the flammable liquids used are presented in Table 2.

The investigation of the samples (thermally loaded and burnt) took place using a cone calorimeter (Dual Cone Calorimeter, Fire Testing Technology, UK). The cone calorimeter and test procedure, as well as test conditions, complied with ISO 5660–1:2015 [17] with two modifications.

The first modification was the removal of the cone heater from the cone calorimeter (manufactured according to ISO 5660–1:2015 [17]), and the replacement of a standard sample holder (intended for solids) by a vessel (suitable for liquid samples). The cone heater was removed so that it would shade the flame when taking photographs. Two stainless steel vessels were used as sample holders. The first vessel had a wall thickness of 2 mm, an internal diameter of 106 mm and a height of 20 mm. The second vessel had a wall thickness of 1 mm, an internal diameter of 75 mm (corresponding to approximately 70% of the diameter of the larger vessel) and a height of 45 mm. The justification for the first modification, the removal of the cone heater and the use of a vessel with an internal diameter of 106 mm (as a liquid sample holder) and why this was a more suitable arrangement for the testing of flammable liquids in a cone calorimeter is described in detail by Martinka et al. [18]. The second vessel was only used to obtain photographs for additional testing of the trained CNNs. The internal diameter of the second vessel (75 mm) was chosen to enable an additional test of the trained CNNs to uncover the effect of a significant change in the diameter and surface of the vessel (a reduction in diameter by 30%, and surface area by 50%), in which the flammable liquid was burning, on the accuracy of the trained CNNs.

The second modification of the test procedure was the placement of a camera (Canon EOS 1200D, Canon Incorporated, Japan) approximately 1500 mm from the vessel containing the sample. The position of the camera is shown in Fig. 1. The imaging frequency was approximately three photographs per second. One thousand photographs of the flame of each sample in the 106-mm-diameter vessel were taken for the training, validation and testing of neuronal network (70% for training, 15% for validation and 15% for testing). Five hundred photographs of the flame of each sample in the 75-mm-diameter vessel were used for the additional test of the trained CNNs. The photographs taken during the first 30 s after sample ignition and during the last 30 s before spontaneous burnout were not used for the training, validation and testing (as photographs were taken during unstable combustion conditions). If a sample burnt out before the necessary number of photographs had been taken, the same liquid was poured into the vessel (after cooling), and the procedure was repeated until the necessary number of photographs had been taken.

The distance of the camera from the edge of the sample vessel was approximately 1500 mm. The ratio between the distance of the camera and the flame diameter was approximately 1500/106 = 1/14. (This ratio allows photographs of an actual fire to be taken at a safe distance, e.g. a distance of approximately 140 m is sufficient for taking a picture of a tank with a diameter of 10 m.) A surface area of 1 × 1 mm of the sample corresponded to approximately 1.7 × 1.7 PX in the photographs.

The specification and settings of the camera are shown in Table 3.

The resolution of photographs taken was 720 × 480 PX (Table 3). The CNNs under investigation require (as an input) images of 227 × 227 PX or 224 × 224 PX (Table 1). Therefore, the photographs were processed prior to the training of the CNNs.

The first step was a preliminary comparison of the CNNs (preliminary study). The photographs used for the training, validation and testing in the preliminary study (the photographs of a flame in the 106-mm-diameter vessel) were processed as follows: (the 720 × 480 PX raw photographs were cropped to 320 × 320 PX and subsequently resized to 227 × 227 PX for AlexNet, and to 224 × 224 PX for both GoogLeNet and ResNet-50). The processing of photographs for the training, validation and testing of the CNNs (in the preliminary study) is shown in Figs. 2 and 3.

The CNNs that had accuracy greater than 95% in the preliminary study were selected for further study (the full study). After the preliminary study, those CNNs (with an accuracy greater than 95%) were repeatedly trained, validated and tested using the photographs of the flame of samples in the 106-mm-diameter vessel, processed as per Fig. 4 (the full study). The processing procedure as per Fig. 4 was as follows: three images of 720 × 480 PX, 320 × 320 PX and 160 × 160 PX were cropped from each photograph. (The relative size of the flame in the photographs changed as a result of cropping.) All the images subsequently underwent further processing, they were rotated. Three images (the first without rotation, the second rotated 15° clockwise and the third rotated 15° counter-clockwise) were produced through rotation of each photograph (720 × 480, 320 × 320 and 160 × 160 PX). These cropped and rotated images were ultimately resized to 224 × 224 PX (as the input for both the GoogLeNet and ResNet-50) and to 227 × 227 PX (the input for the AlexNet). Nine different images (differing in relative size and flame angle) were obtained from the processing of a single raw photograph. Figure 5 shows the example of the images of a propanol flame obtained from a single raw photograph (720 × 480 PX) after processing. All the images created according to the process detailed in Fig. 4, from a single raw photograph, were only used in a single set (the training, validation or testing set—the use of images obtained by processing the same photograph in two or more sets simultaneously, e.g. in training and testing, would lead to biased results).

Propanol flame in the 106-mm-diameter vessel (raw photograph and images processed according to Fig. 4)

In order to verify whether a change in the size of the vessel surface area (a reduction of 50%), in which the liquid is burning, had a considerable effect on the accuracy of the trained CNNs, additional tests were carried out. Five hundred photographs of each sample burning in the 75-mm-diameter vessel were used for the additional tests. (Photographs of flames in a vessel of this diameter were not used in the training, validation or testing of the CNNs, neither in the preliminary nor full study.) The additional tests were performed using three independent sets of images (each set contained 500 photographs of ethanol, pentane and propanol). The method used to process the images for the first, second and third sets (for additional testing) is presented in Fig. 6. The propanol flame from the first, second and third set (after processing according to Fig. 6) is shown in Fig. 7. The processing shown in Figs. 6 and 7 changes the relative size of the flame in the image (the relative flame size is at its smallest in the images of the first test set, and largest in the third test set).

Propanol flame in the 75-mm-diameter vessel (raw photograph and images processed according to Fig. 6)

The number of raw photographs and images obtained through processing for the training, validation and testing of the CNNs (for the preliminary study, full study and additional tests) is presented in Table 4.

Raw photographs used in the full study and in additional tests can be found in the supplementary materials: S1_Raw_Photographs_Full_Study and S2_Raw_Photographs_Additional_Tests.

Results and discussion

The fundamental and most important fire characteristics of a substance, according to Babrauskas and Peacock [19], is the heat release rate (HRR) which has the unit (kW m−2 = kJ s−1 m−2). Two substances with similar HRRs have similar fire scenarios (under comparable external conditions). The HRR of the samples used for the training, validation and testing of investigated CNNs is presented in Fig. 8.

Figure 8 demonstrates that ethanol and propanol have very similar heat release rates. Very similar specific mass loss rates were recorded for ethanol and propanol (ethanol 10.9 g m−2 s−1 and propanol 11.2 g m−2 s−1). Hence, these samples enable the assessment of the accuracy of the CNNs under investigation in the recognition of burning substances with very similar fire characteristics. A significantly higher (approximately five times) HRR was recorded for pentane (Fig. 8). A higher specific mass loss rate was also recorded for pentane (33.3 g m−2 s−1). Hence, this flammable liquid enables an assessment of whether there was a difference in the accuracy of the CNNs in the recognition of a flammable liquid with significantly different fire characteristics to those flammable liquids with very similar fire characteristics.

Even though, according to [19], HRR is the most important fire characteristic, the ratio of the concentration of carbon dioxide (CO2) to carbon monoxide (CO) in combustion products, which, according to [20, 21], is characterised by combustion efficiency (a low ratio indicates a low combustion efficiency), is also an important parameter in the assessment of the similarities of the combustion processes. The ratio of the concentration of CO2 to CO of the sample flammable liquids is shown in Fig. 9. As Figs. 8, 9 demonstrates that the combustion processes of ethanol and propanol are very similar, while the combustion process of pentane differs significantly from both ethanol and propanol. Further fire characteristics of the samples are described in detail in [22,23,24].

The accuracy of the CNNs under investigation in the preliminary study (in the recognition of the images used in training, validation and testing) is presented in Table 5. The accuracy of the recognition of test images is decisive in the assessment of the accuracy of the CNN. The confusion matrices of the CNNs (in the recognition of the test images in the preliminary study) are presented in Fig. 10.

Confusion matrices for AlexNet, GoogLeNet and ResNet-50 for the test images during the preliminary study (photographs processed according to Fig. 2)

The data presented in Table 5 and Fig. 10 demonstrates that an accuracy of at least 98% was recorded for all the CNNs investigated in the preliminary study (in the recognition of test images). Differences in accuracy (ranging from 98.00 to 99.11%) between the CNNs are negligible from a practical standpoint. However, differences in the time necessary to train the CNNs (ranging from 111 to 1124 min) are very significant. The highest accuracy and lowest time for training were recorded for AlexNet (Table 5). ResNet-50 did not incorrectly classify the flames from the alcohols (ethanol and propanol) as flame from pentane (Fig. 10).

As minimum accuracy of 98% was achieved by all the CNNs in the preliminary study, all of them entered the full study. In the full study CNNs were trained, validated and tested again, using images processed according to Fig. 4.

The accuracy of the CNNs investigated in the full study (for training, validation and test images processed according to Fig. 4) together with the training times is shown in Table 6. The confusion matrices for the full study of test images processed according to Fig. 4 are shown in Fig. 11.

Confusion matrices for AlexNet, GoogLeNet and ResNet-50 for the test images during the full study (photographs processed according to Fig. 4)

The data provided in Table 6 show that all the CNNs achieved an accuracy that exceeded 99% in the test. From a practical standpoint the differences in accuracy are negligible. However, the differences in training times are very significant. (Similar conclusions had already been drawn from the preliminary study.) From this perspective (the highest accuracy and shortest training time), CNN AlexNet appears to be the most suitable network for the recognition of burning liquids. However, a final conclusion can only be drawn after three additional tests. The higher level of accuracy in the full study compared to the preliminary study (Tables 5 and 6) is due to the larger number of images used to train the CNNs in the full study (Table 4).

The confusion matrices for the CNNs in the recognition of test images (during the full study) are presented in Fig. 11. CNNs AlexNet and GoogLeNet are less accurate at distinguishing ethanol from propanol and propanol from ethanol than they are at distinguishing pentane from ethanol and pentane from propanol (Fig. 11). A different trend was recorded for ResNet-50, which demonstrated its lowest accuracy in distinguishing pentane from propanol (Fig. 11).

The final conclusion concerning the accuracy of the CNNs was only drawn after the three additional tests. The photographs of the flame of samples in a 75-mm-diameter vessel were used for the additional tests. (The photographs of a flame in a vessel of that diameter were not used in the training, validation or testing, neither in the preliminary nor the full study.) The raw photographs were processed according to Figs. 6 and 7 before they were used in the additional tests (three test sets of photographs were generated: first, second and third). Photographs in the first, second and third sets differ in the relative size of the flame (Figs. 6 and 7). The relative size of the flame is at its smallest in the first test set, and at its largest in the third set (Fig. 7).

The accuracy of the CNNs for the first, second and third additional tests is presented in Table 7, which shows significant differences in the accuracy of the CNNs. Table 7 also demonstrates that the relative flame size has a considerable effect on the accuracy of the CNNs. The training times (Table 6) and accuracy within the additional tests (Table 7) demonstrate that AlexNet is the most suitable network for the recognition of burning substances from photographs processed prior to analysis: cropping from an original size of 720 × 480 PX to 160 × 160 PX and subsequent resize to 227 × 227 PX, all according to Figs. 6 and 7.

The confusion matrix is a better indication of performance than the overall accuracy of a CNN. The confusion matrices of the CNNs from the additional tests (first, second and third) are presented in Figs. 12–14.

Figure 12 shows the very low level of accuracy of all the CNNs from the first additional test. (Images created from raw photographs (720 × 480 PX) resized to 224 × 224 or 227 × 227 PX—these images had the smallest relative flame size.) Very low levels of accuracy, especially in pentane classification, were recorded for all the CNNs during the first additional test. It is likely due to the small relative size of the flame that results from the image processing used for the first additional test (Figs. 6 and 7).

Images created from raw photographs (720 × 480 PX), cropped to 320 × 320 PX and then resized to 224 × 224 or 227 × 227 PX (images with a medium relative flame size) were used in the second additional test (Fig. 13). Very low levels of accuracy were also recorded in this additional test for GoogLeNet and ResNet-50, especially in the recognition of pentane (GoogLeNet also in the recognition of propanol). Compared to GoogLeNet and ResNet-50, the accuracy of AlexNet was higher; however, it too was lower in the recognition of propanol. Despite the fact that AlexNet demonstrated the highest level of accuracy in the second additional test, up to 218 (43.2%) photographs of propanol were wrongly recognised as ethanol. Figures 12 and 13 indicate that photographs (images) with a certain minimum (critical) relative flame size need to be used to allow the accurate recognition of burning substances by CNNs.

Images created from raw photographs (720 × 480 PX) cropped to 160 × 160 PX and then resized to 224 × 224 or 227 × 227 PX (images with the largest relative flame size) were used in the third additional test (Fig. 14). Very low accuracy levels were recorded in this third additional test for GoogLeNet and ResNet-50 (as in the first and second additional tests) in the recognition of pentane. Very high accuracy in the recognition of ethanol was recorded for AlexNet. Accuracy levels of 75.6% and 62.4% were recorded for AlexNet in the differentiation of pentane from propanol and propanol from ethanol. The low accuracy levels in the differentiation between propanol and ethanol recorded for Alexnet suggest that it is also problematic for CNNs with a high overall (summary) level of accuracy to distinguish between flammable liquids with very similar fire characteristics.

The accuracy achieved by AlexNet in the third additional test can be increased through the application of the following algorithm. Ten photographs of a single sample are taken (over several seconds). The photographs are processed according to Fig. 6 (cropped to 160 × 160 PX and resized to 227 × 227 PX) and then analysed in the trained AlexNet. The burning liquid recognition is achieved when at least six out of ten analysed photographs have the identical classification (thus increasing accuracy to 96%). The accuracy of the CNN after the application of this algorithm is expressed by Eq. (1).

AC: accuracy of the CNN after the application of the algorithm (−).P(M/n): probability of the correct recognition of n out of M images (−).

To assess the accuracy of the CNNs under investigation, it is useful to compare them to CNNs used in the recognition of common objects. According to Blanco [25], the accuracy of CNNs in the recognition of common objects is 96%. Sharma et al. [26] state an accuracy of 0–99% (for most objects 50–90%). The investigated CNNs achieved comparable accuracy levels in both the preliminary (Table 5) and full (Table 6) studies. The accuracy of AlexNet in the third additional test (almost 80%) is comparable to the accuracy stated by [26], yet significantly lower than the accuracy according to [25]. The application of the algorithm described above resulted in an increase in the accuracy of AlexNet in the third additional test from 80 to 96%, which is a value which is identical to that stated by Blanco [25] and comparable to the upper accuracy level published by Sharma et al. [26].

A comparison of the accuracy of the investigated CNNs to CNNs used in fire detection is even more useful. According to [11,12,13,14,15,16], the accuracy achieved by CNNs in fire detection ranges from 94 to 99% (rarely above 99%). The accuracy level of AlexNet in the third additional test (almost 96%) after the application of the aforementioned algorithm is in the given range. This implies that following the processing of photographs according to Fig. 6 (third file), AlexNet demonstrates an accuracy in the recognition of the type of burning liquid comparable to CNNs that are today commonly applied to fire detection.

Conclusions

Three CNNs, AlexNet, GoogLeNet and ResNet-50, used for the recognition of burning substances from photographs of their flames, were trained in this study. The CNNs were trained using photographs of the flames of ethanol, propanol and pentane in a 106-mm-diameter vessel. An accuracy of 98–99% was recorded for these CNNs during the tests. The trained CNNs subsequently underwent three additional tests, the recognition of the sample liquids from photographs of flames in a 75-mm-diameter vessel. The additional tests differed in the relative size of the flames captured in photographs (the first test with the lowest size, the second one with a medium size flame and the third with the largest relative size of flame). The highest accuracy level (almost 80%) recorded by AlexNet came from the third additional test (with the largest relative size of flame). This accuracy is comparable to the accuracy achieved by the majority of CNNs in the recognition of common objects, but lower than the accuracy of common CNNs used in fire detection (about 94–99%). Therefore, the accuracy of AlexNet was increased through the use of an algorithm based on the recognition of ten photographs (taken over several seconds) of the same substance burning in the same vessel. The recognition of the burning substances was made on the basis of the identical classification of at least six out of ten analysed photographs. This algorithm increased the accuracy of AlexNet to 96%. This level of accuracy is sufficient for the practical application of AlexNet in the recognition of burning substances.

Declared accuracy of the AlexNet improved by the described algorithm (96%) is valid for recognition of investigated liquids burning in the vessels with internal diameter of 106 mm ± 30% during laboratory conditions.

Availability of data

All data are available in the manuscript.

Code availability

Not applicable.

References

Danzer K. Analytical chemistry: theoretical and metrological fundamentals. 1st ed. Berlin: Springer; 2007.

Stauffer E, Dolan JA, Newman R. Fire debris analysis. 1st ed. Cambridge: Academic Press; 2008.

Mei X, Li Z, Bagherzadeh SA, Karimipour A, Bahrami M, Karimipour A. Development of the ANN–KIM composed model to predict the nanofluid energetic thermal conductivity via various types of nano-powders dispersed in oil. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-10212-0.

Wu T, Fang GG, Liang L, Lin Y, Xiong ZX. Four kinds of algorithms used for the determination of pulpwood properties by near infrared spectroscopy. Chem Indus For Prod. 2016;36:63–70.

Xu Q, Majlingova A, Zachar M, Jin C, Jiang Y. Correlation analysis of cone calorimetry test data assessment of the procedure with tests of different polymers. J Therm Anal Calorim. 2012;110:65–70.

Mou L, Jin Z. Tree-based convolutional neural networks principles and applications. 1st ed. Singapore: Springer; 2018.

Aghdam HH, Heravi EJ. Guide to convolutional neural networks: a practical application to traffic-sign detection and classification. 1st ed. Cham: Springer; 2017.

Lu L, Wang X, Carneiro G, Yang L. Deep learning and convolutional neural networks for medical imaging and clinical informatics. 1st ed. Cham: Springer; 2019.

Aggarwal CC. Neural networks and deep learning. 1st ed. Cham: Springer; 2018.

Li P, Zhao W. Image fire detection algorithms based on convolutional neural networks. Case Stud Therm Eng. 2020. https://doi.org/10.1016/j.csite.2020.100625.

Hu Y, Lu X. Real-time video fire smoke detection by utilizing spatial-temporal ConvNet features. Multimed Tool Appl. 2018. https://doi.org/10.1007/s11042-018-5978-5.

Namozov A, Cho YI. An efficient deep learning algorithm for fire and smoke detection with limited data. Adv Electr Comput Eng. 2018;18:121–8.

Mao W, Wang W, Dou Z, Li Y. Fire recognition based on multi-channel convolutional neural network. Fire Technol. 2018;54:531–54.

Muhammad K, Ahmad J, Baik SW. Early fire detection using convolutional neural networks during surveillance for effective disaster management. Neurocomputing. 2018;288:30–42.

Tao C, Zhang J, Wang P. Smoke detection based on deep convolutional neural networks. In: Wang P, Chen W, Xu L, editors. Proceedings of second international conference on industrial informatics: computing technology, intelligent technology, industrial information integration. Wuhan: IEEE; 2016. pp. 150–153.

Yin Z, Wan B, Yuan F, Xia X, Shi J. A deep normalization and convolutional neural network for image smoke detection. IEEE ACCESS. 2017;5:18429–38.

ISO 5660–1:2015. Reaction to fire tests: Heat release, smoke production and mass loss rate - Part 1: Heat release rate (cone calorimeter method) and smoke production rate (dynamic measurement).

Martinka J, Chrebet T, Balog K. An assessment of petrol fire risk by oxygen consumption calorimetry. J Therm Anal Calorim. 2014;117:325–32.

Babrauskas V, Peacock RD. Heat release rate: the single most important variable in fire hazard. Fire Saf J. 1992;18:255–72.

Ferek RJ, Reid JS, Hobbs PV, Blake DR, Liousse C. Emission factors of hydrocarbons, halocarbons, trace gases and particles from biomass burning in Brazil. J Geophys Res Atmos. 1998. https://doi.org/10.1029/98JD00692.

Wang Y, Munger JW, Xu S, McElroy MB, Hao J, Nielsen CP, Ma H. CO2 and its correlation with CO at a rural site near Beijing: implications for combustion efficiency in China. Atmos Chem Phys. 2010;10:8881–97.

Martinka J, Rantuch P, Wachter I. Impact of water content on energy potential and combustion characteristics of methanol and ethanol fuels. Energies. 2019. https://doi.org/10.3390/en12183491.

Hurley MJ. SFPE handbook of fire protection engineering. 5th ed. New York: Springer; 2016.

Karlsson B, Quintiere JG. Enclosure fire dynamics. 1st ed. Boca Raton: CRC Press; 2000.

Blanco GE. A neural networks benchmark for image classification. 1st ed. Madrid: Polytechnic University of Madrid; 2017.

Sharma N, Jain V, Mishra A. An analysis of convolutional neural networks for image classification. Procedia Comput Sci. 2018;132:377–84.

Acknowledgements

This work was supported by the Slovak Research and Development Agency under the contract No. APVV-16-0223.

Funding

This work was supported by the Slovak Research and Development Agency under the contract No. APVV-16–0223.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Martinka, J., Nečas, A. & Rantuch, P. The recognition of selected burning liquids by convolutional neural networks under laboratory conditions. J Therm Anal Calorim 147, 5787–5799 (2022). https://doi.org/10.1007/s10973-021-10903-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10903-2