Abstract

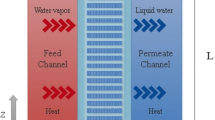

In this paper, a 1D model of direct contact membrane distillation is presented in which all fluid properties are temperature-dependent. In addition, a Nusselt number (Nu) relationship for developing flow in ducts (accounting for both thermal and hydrodynamic effects) is used to obtain the convective heat transfer coefficient at each side of the membrane. Simulated mass flux shows very good agreement with experimental measurements at various feed temperature, flow rate and concentration. A comprehensive sensitivity analysis of all operational and geometrical parameters, as well as Nu estimation parameters on water mass flux across the membrane \((J_{\text{m}} )\) and thermal efficiency, is also done. To determine the relative importance of each parameter, a multi-parameter sensitivity analysis (MPSA) based on the Monte Carlo method is applied, and the sensitivity index of each parameter at the defined range is computed. Results show that \(J_{\text{m}}\) is highly sensitive to bulk feed inlet temperature (\(T_{{{\text{in}},{\text{f}}}}\)) while both \(J_{\text{m}}\) and thermal efficiency are highly sensitive to membrane porosity. Results show that among all parameters, just membrane porosity is highly sensitive which affects both mass flux and thermal efficiency especially at low \(T_{{{\text{in}}.{\text{f}}}}\).

Similar content being viewed by others

Abbreviations

- A :

-

Cross-sectional area (m2)

- B :

-

Membrane flux coefficient (kg m−2 Pa−1 s−1)

- D :

-

Water diffusion coefficient (m2 s−1)

- dA :

-

Area element (m2)

- Dz :

-

Length element (m)

- F :

-

Friction factor

- H :

-

Specific enthalpy (J kg−1)

- \(h_{\text{ch}}\) :

-

Channel height (m)

- \(h_{\text{m}}\) :

-

Membrane thickness \((\upmu{\text{m}})\)

- \(h_{\text{t}}\) :

-

Convective heat transfer coefficients (W m−2 K−1)

- \(J_{\text{m}}\) :

-

Membrane water vapor mass flux (kg m−2 s−1)

- K :

-

Gain coefficient and thermal conductivity (W m−1 K−1)

- L :

-

Channel length (m)

- M :

-

Blending parameter

- \(M_{\text{w}}\) :

-

Water molecular weight (kg mol−1)

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- P :

-

Pressure (Pa)

- \(Q\) :

-

Volume flow rate (L min−1)

- Q :

-

Heat flux (W m−2)

- R :

-

Gas constant (J K−1 mol−1)

- \(r_{\text{p}}\) :

-

Pore size (\(\upmu{\text{m}}\))

- S :

-

Salinity (ppm)

- T :

-

Temperature (K or °C)

- W :

-

Channel width (m)

- Z :

-

Z-axis (flow direction) (m)

- \(z^{*}\) :

-

Dimensionless position

- \(\gamma\) :

-

Activity coefficient and shape parameter

- \(\delta\) :

-

Membrane thickness (\(\upmu{\text{m}}\))

- \(\varepsilon\) :

-

Aspect ratio of duct

- \(\epsilon\) :

-

Membrane porosity

- \(\eta\) :

-

Thermal efficiency

- \(\kappa\) :

-

Sensitivity index

- \(\tau\) :

-

Membrane tortuosity

- a:

-

Air

- ave:

-

Average

- b:

-

Bulk

- f:

-

Feed

- g:

-

Gas

- in:

-

Inlet

- m:

-

Membrane

- p:

-

Permeate

- s:

-

Solid

- v:

-

Vapor

- w:

-

Water

- AGMD:

-

Air gap membrane distillation

- DCMD:

-

Direct contact membrane distillation

- MD:

-

Membrane distillation

- MPSA:

-

Multi-parameter sensitivity analysis

- \({\text{Nu}}\) :

-

Nusselt no

- \({ \Pr }\) :

-

Prandtl no

- PTFE:

-

Polytetrafluoroethylene

- Re:

-

Reynolds no

- SGMD:

-

Swiping gas membrane distillation

- VMD:

-

Vacuum membrane distillation

References

Kiss AA, Kattan Readi OM. An industrial perspective on membrane distillation processes. J Chem Technol Biotechnol. 2018;93(8):2047–55.

Hausmann A, et al. Performance assessment of membrane distillation for skim milk and whey processing. J Dairy Sci. 2014;97(1):56–71.

Al-Obaidani S, et al. Potential of membrane distillation in seawater desalination: thermal efficiency, sensitivity study and cost estimation. J Membr Sci. 2008;323(1):85–98.

Macedonio F, et al. Direct contact membrane distillation for treatment of oilfield produced water. Sep Purif Technol. 2014;126:69–81.

Saffarini RB, Summers EK, Arafat HA. Technical evaluation of stand-alone solar powered membrane distillation systems. Desalination. 2012;286:332–41.

Hausmann A, et al. Integration of membrane distillation into heat paths of industrial processes. Chem Eng J. 2012;211:378–87.

Walton J, et al. Solar and waste heat desalination by membrane distillation. Desalin Water Purif Res Dev Prog Rep. 2004;81:20.

Mericq J-P, Laborie S, Cabassud C. Vacuum membrane distillation of seawater reverse osmosis brines. Water Res. 2010;44(18):5260–73.

Ji X, et al. Membrane distillation-crystallization of seawater reverse osmosis brines. Sep Purif Technol. 2010;71(1):76–82.

Drioli E, et al. Integrated membrane operations in desalination processes. Desalination. 1999;122(2–3):141–5.

González D, Amigo J, Suárez F. Membrane distillation: Perspectives for sustainable and improved desalination. Renew Sustain Energy Rev. 2017;80:238–59.

Alkhudhiri A, Darwish N, Hilal N. Membrane distillation: a comprehensive review. Desalination. 2012;287:2–18.

Khayet M. Membranes and theoretical modeling of membrane distillation: a review. Adv Coll Interface Sci. 2011;164(1–2):56–88.

Ali A, et al. Optimization of module length for continuous direct contact membrane distillation process. Chem Eng Process. 2016;110:188–200.

Ali A, et al. Designing and optimization of continuous direct contact membrane distillation process. Desalination. 2018;426:97–107.

Khalifa A, et al. Experimental and theoretical investigations on water desalination using direct contact membrane distillation. Desalination. 2017;404:22–34.

Manawi YM, et al. A predictive model for the assessment of the temperature polarization effect in direct contact membrane distillation desalination of high salinity feed. Desalination. 2014;341:38–49.

Schofield R, et al. Factors affecting flux in membrane distillation. Desalination. 1990;77:279–94.

Bandini S, Gostoli C, Sarti G. Role of heat and mass transfer in membrane distillation process. Desalination. 1991;81(1–3):91–106.

Abu Al-Rub FA, Banat F, Beni-Melhim K. Parametric sensitivity analysis of direct contact membrane distillation. Sep Sci Technol. 2002;37(14):3245–71.

Abu Al-Rub FA, Banat F, Bani-Melhem K. Sensitivity analysis of air gap membrane distillation. Separ Sci Technol. 2003;38(15):3645–67.

Banat F, Al-Rub FA, Bani-Melhem K. Desalination by vacuum membrane distillation: sensitivity analysis. Sep Purif Technol. 2003;33(1):75–87.

Hwang HJ, et al. Direct contact membrane distillation (DCMD): Experimental study on the commercial PTFE membrane and modeling. J Membr Sci. 2011;371(1–2):90–8.

Bahmanyar A, Asghari M, Khoobi N. Numerical simulation and theoretical study on simultaneously effects of operating parameters in direct contact membrane distillation. Chem Eng Process. 2012;61:42–50.

Wu HY, Wang R, Field RW. Direct contact membrane distillation: An experimental and analytical investigation of the effect of membrane thickness upon transmembrane flux. J Membr Sci. 2014;470:257–65.

Bouchrit R, et al. Direct contact membrane distillation: Capability to treat hyper-saline solution. Desalination. 2015;376:117–29.

Lee J-G, et al. Performance modeling of direct contact membrane distillation (DCMD) seawater desalination process using a commercial composite membrane. J Membr Sci. 2015;478:85–95.

Hayer H, Bakhtiari O, Mohammadi T. Simulation of momentum, heat and mass transfer in direct contact membrane distillation: A computational fluid dynamics approach. J Ind Eng Chem. 2015;21:1379–82.

Deshpande J, Nithyanandam K, Pitchumani R. Analysis and design of direct contact membrane distillation. J Membr Sci. 2017;523:301–16.

Imdakm A, Matsuura T. Simulation of heat and mass transfer in direct contact membrane distillation (MD): the effect of membrane physical properties. J Membr Sci. 2005;262(1–2):117–28.

Jantaporn W, Ali A, Aimar P. Specific energy requirement of direct contact membrane distillation. Chem Eng Res Des. 2017;128:15–26.

Ullah R, et al. Energy efficiency of direct contact membrane distillation. Desalination. 2018;433:56–67.

Hitsov I, et al. Modelling approaches in membrane distillation: a critical review. Sep Purif Technol. 2015;142:48–64.

Muzychka Y, Yovanovich M. Laminar forced convection heat transfer in the combined entry region of non-circular ducts. J Heat Transfer. 2004;126(1):54–61.

Curcio E, Drioli E. Membrane distillation and related operations—a review. Separ Purif Rev. 2005;34(1):35–86.

Summers EK, Arafat HA. Energy efficiency comparison of single-stage membrane distillation (MD) desalination cycles in different configurations. Desalination. 2012;290:54–66.

Rao G, Hiibel SR, Childress AE. Simplified flux prediction in direct-contact membrane distillation using a membrane structural parameter. Desalination. 2014;351:151–62.

Chung S, et al. Design strategy for networking membrane module and heat exchanger for direct contact membrane distillation process in seawater desalination. Desalination. 2014;349:126–35.

Khayet M, Velázquez A, Mengual JI. Modelling mass transport through a porous partition: effect of pore size distribution. J Non-Equilib Thermodyn. 2004;29(3):279–99.

Lawson KW, Lloyd DR. Membrane distillation. J Membr Sci. 1997;124(1):1–25.

Khayet M, Godino M, Mengual J. Modelling transport mechanism through a porous partition. J Non-Equilib Thermodyn. 2001;26(1):1–14.

Phattaranawik J, Jiraratananon R. Direct contact membrane distillation: effect of mass transfer on heat transfer. J Membr Sci. 2001;188(1):137–43.

Martínez L, Rodríguez-Maroto JM. On transport resistances in direct contact membrane distillation. J Membr Sci. 2007;295(1–2):28–39.

Martı́nez-Dı́ez L, Vazquez-Gonzalez MI. Temperature and concentration polarization in membrane distillation of aqueous salt solutions. J Membrane Sci. 1999;156(2):265–73.

Choi J, Harvey JW, Conklin MH. Use of multi-parameter sensitivity analysis to determine relative importance of factors influencing natural attenuation of mining contaminants. Report: US Geol Surv Water-Resourc Investig Prog; 1999.

Zhao D, et al. Study of the modeling parameter effects on the polarization characteristics of the PEM fuel cell. Int J Hydrogen Energy. 2016;41(47):22316–27.

Keshavarzzadeh Amir H. Design and bio-inspired optimization of direct contact membrane distillation for desalination based on constructal law. Sci Rep. 2020;10:16790. https://doi.org/10.1038/s41598-020-73964-7.

Ajili SH, Haratian M, Karimipour A, Bach QV. Non-uniform slab heating pattern in a preheating furnace to reduce fuel consumption: burners’ load distribution effects through semitransparent medium via discreet ordinates’ thermal radiation and k–? Turbulent model. Int J Thermophys. 2020;41(9):128.

Dehkordi KG, Karimipour A, Afrand M, Toghraie D, Isfahani AHM. The electric field and microchannel type effects on H 2 O/Fe 3 O 4 nanofluid boiling process: molecular dynamics study. Int J Thermophys. 2020;41(9):132.

Asgari A, Nguyen Q, Karimipour A, Bach QV, Hekmatifar M, Sabetvand R. Develop molecular dynamics method to simulate the flow and thermal domains of H 2 O/Cu nanofluid in a nanochannel affected by an external electric field. Int J Thermophys. 2020;41(9):126.

Salimpour MR, Darvanjooghi MHK, Abdollahi A, Karimipour A, Goodarzi M. Providing a model for Csf according to pool boiling convection heat transfer of water/ferrous oxide nanofluid using sensitivity analysis. Int J Numer Meth Heat Fluid Flow. 2019;30(6):2867–81.

Peng Y, Zahedidastjerdi A, Abdollahi A, Amindoust A, Bahrami M, Karimipour A, Goodarzi M. Investigation of energy performance in a U-shaped evacuated solar tube collector using oxide added nanoparticles through the emitter, absorber and transmittal environments via discrete ordinates radiation method. J Therm Anal Calorim. 2020;139(4):2623–31.

Sun C, Fard BE, Karimipour A, Abdollahi A, Bach QV. Producing ZrO2/LP107160 NF and presenting a correlation for prediction of thermal conductivity via GMDH method: An empirical and numerical investigation. Phys E Low-dimens Syst Nanostruct. 2020;1:114511.

Li Z, Asadi S, Karimipour A, Abdollahi A, Tlili I. Experimental study of temperature and mass fraction effects on thermal conductivity and dynamic viscosity of SiO2-oleic acid/liquid paraffin nanofluid. Int Commun Heat Mass Transfer. 2020;110:104436.

Mozaffari M, D’Orazio A, Karimipour A, Abdollahi A, Safaei MR. Lattice Boltzmann method to simulate convection heat transfer in a microchannel under heat flux. Int J Numer Meth Heat Fluid Flow. 2019;30(6):3371–98.

Karimipour A, Bagherzadeh SA, Taghipour A, Abdollahi A, Safaei MR. A novel nonlinear regression model of SVR as a substitute for ANN to predict conductivity of MWCNT-CuO/water hybrid nanofluid based on empirical data. Physica A. 2019;521:89–97.

Sedeh RN, Abdollahi A, Karimipour A. Experimental investigation toward obtaining nanoparticles’ surficial interaction with basefluid components based on measuring thermal conductivity of nanofluids. Int Commun Heat Mass Transfer. 2019;103:72–82.

Dehghani Y, Abdollahi A, Karimipour A. Experimental investigation toward obtaining a new correlation for viscosity of WO 3 and Al 2 O 3 nanoparticles-loaded nanofluid within aqueous and non-aqueous basefluids. J Therm Anal Calorim. 2019;135(1):713–28.

Abdollahi A, Darvanjooghi MHK, Karimipour A, Safaei MR. Experimental study to obtain the viscosity of CuO-loaded nanofluid: effects of nanoparticles’ mass fraction, temperature and basefluid’s types to develop a correlation. Meccanica. 2018;53(15):3739–57.

Aghakhani S, Pordanjani AH, Karimipour A, Abdollahi A, Afrand M. Numerical investigation of heat transfer in a power-law non-Newtonian fluid in a C-Shaped cavity with magnetic field effect using finite difference lattice Boltzmann method. Comput Fluids. 2018;176:51–67.

Karimipour A, Ghasemi S, Darvanjooghi MHK, Abdollahi A. A new correlation for estimating the thermal conductivity and dynamic viscosity of CuO/liquid paraffin nanofluid using neural network method. Int Commun Heat Mass Transfer. 2018;92:90–9.

Safaei MR, Karimipour A, Abdollahi A, Nguyen TK. The investigation of thermal radiation and free convection heat transfer mechanisms of nanofluid inside a shallow cavity by lattice Boltzmann method. Physica A. 2018;509:515–35.

Acknowledgements

This work was funded by the Deanship of Scientific Research (DSR), King Abdulaziz University, under grant No. (24-135-35-HiCi). The authors, therefore, acknowledge technical and financial support of KAU.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Al-Turki, Y.A., Mebarek-Oudina, F., Ahmadian, A. et al. Flat sheet direct contact membrane distillation desalination system using temperature-dependent correlations: thermal efficiency via a multi-parameter sensitivity analysis based on Monte Carlo method. J Therm Anal Calorim 144, 2641–2652 (2021). https://doi.org/10.1007/s10973-020-10503-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10503-6