Abstract

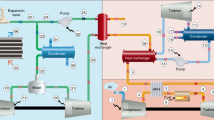

Ensuring efficient operation of energy conversion systems in terms of economics and ecology is a prime objective that should be addressed within the design, optimization, and development stages of such systems. Adopting appropriate measures for accurate assessment and comprehensive evaluation of thermodynamic systems is a sheer necessity for accomplishing this purpose. In this study, the newly developed emergy-based exergoeconomic (i.e., emergoeconomic) and emergy-based exergoenvironmental (i.e., emergoenvironmental) analyses have been employed to assess a combined power and cooling system, including a gas turbine cycle, a steam Rankine cycle, and an integrated organic Rankine cycle-vapor compression refrigeration (ORC-VCR) subsystem serving as a waste heat recovery unit. The merit of emergy-based methods is that they can evaluate and express results by an identical unit of measurement (i.e., sej) which enables us to undertake a fair and accurate comparison between the methods in question. The results showed that the combustion chamber, with the total economic emergy rate of 6.83E13 (sej h−1) and the total ecological emergy rate of 6.05E14 (sej h−1), was the most critical component in the entire system from both the economic and ecological viewpoints. Moreover, a parametric study was carried out on the entire system, as well as the ORC-VCR unit, to examine the effect of design parameters on the emergy-based monetary and ecological performances. Increasing the air compressor pressure ratio from 6 to 11 enhanced the entire system’s both emergy-based performances by almost 8%, followed by improvements made by the gas turbine isentropic efficiency and combustor inlet temperature, with 6.5% and 5.5%, respectively. However, other design parameters exerted limited impact. Regarding the ORC-VCR, raising the ORC turbine inlet temperature and the isentropic efficiencies associated with the ORC turbine and VCR compressor improved the emergy-based performances, while the reverse was observed for the ORC condenser and evaporator temperature rise.

Similar content being viewed by others

Abbreviations

- \(\dot{E}_{{}}\) :

-

Exergy rate (kW)

- \(f_{\text{m}}\) :

-

Emergoeconomic factor (%)

- \(f_{\text{n}}\) :

-

Emergoenvironmental factor (%)

- \(hy\) :

-

Operation hours per year (h year-1)

- LS:

-

Lifespan (year)

- LT:

-

Lifetime (h)

- m :

-

Specific monetary emergy (sej GJ−1)

- \(\dot{M}\) :

-

Monetary emergy rate (sej h−1)

- M :

-

Component’s mass (kg)

- n :

-

Specific ecological emergy (sej GJ−1º)

- \(\dot{N}\) :

-

Ecological emergy rate (sej h−1)

- \(\dot{Q}\) :

-

Heat transfer rate (kW)

- r :

-

Relative emergy difference (%)

- SEM:

-

Exergy-based specific emergy of a material (sej g-1)

- \(\dot{U}\) :

-

Component-related monetary emergy rate (sej h-1)

- \(\dot{V}\) :

-

Component-related ecological emergy rate (sej h-1)

- \(\dot{W}\) :

-

Power (kW)

- \(\dot{Z}\) :

-

Investment cost rate ($ h−1)

- \(\beta\) :

-

Scale factor

- \(\psi\) :

-

Emergy-based performance (%)

- D:

-

Destruction

- F:

-

Fuel

- i:

-

Flow stream number

- in:

-

Inlet

- k:

-

Component number

- M/m:

-

Monetary

- N/n:

-

Ecological

- net:

-

Net

- out:

-

Outlet

- P:

-

Product

- Q:

-

Heat

- system:

-

System

- tot:

-

Total

- W:

-

Work

- CI:

-

Capital investment

- CO:

-

Construction

- DI:

-

Disposal

- OM:

-

Operating and maintenance

- AC:

-

Air compressor

- APH:

-

Air preheater

- CC:

-

Combustion chamber

- EVA:

-

Evaporator

- EXV:

-

Expansion valve

- GT:

-

Gas turbine

- GTC:

-

Gas turbine cycle

- MC:

-

Mixing chamber

- OC:

-

ORC condenser

- OP:

-

ORC pump

- ORC-VCR:

-

Organic Rankine cycle-vapor compression refrigeration

- OT:

-

ORC turbine

- SB:

-

Steam boiler

- SC:

-

Steam condenser

- SP:

-

Steam pump

- SPECO:

-

Specific exergy costing

- SRC:

-

Steam Rkine cycle

- ST:

-

Steam turbine

- VC:

-

VCR compressor

References

Ahmadi MH, Banihashem SA, Ghazvini M, Sadeghzadeh M. Thermo-economic and exergy assessment and optimization of performance of a hydrogen production system by using geothermal energy. Energy Environ. 2018;29:1373–92.

Naseri A, Bidi M, Ahmadi MH, Saidur R. Exergy analysis of a hydrogen and water production process by a solar-driven transcritical CO2 power cycle with Stirling engine. J Clean Prod. 2017;158:165–81.

Naseri A, Bidi M, Ahmadi MH. Thermodynamic and exergy analysis of a hydrogen and permeate water production process by a solar-driven transcritical CO2 power cycle with liquefied natural gas heat sink. Renew Energy. 2017;113:1215–28.

Vakilabadi MA, Bidi M, Najafi AF, Ahmadi MH. Energy, exergy analysis and performance evaluation of a vacuum evaporator for solar thermal power plant zero liquid discharge systems. J Therm Anal Calorim. 2020;139:1275–90.

Ghazvini M, Sadeghzadeh M, Ahmadi MH, Moosavi S, Pourfayaz F. Geothermal energy use in hydrogen production: a review. Int J Energy Res. 2019;43:7823–51.

Chahartaghi M, Kalami M, Ahmadi MH, Kumar R, Jilte R. Energy and exergy analyses and thermo-economic optimization of geothermal heat pump for domestic water heating. Int J Low-Carbon Technol. 2019;14:108–21.

Ghasempour R, Nazari MA, Ebrahimi M, Ahmadi MH, Hadiyanto H. Multi-criteria decision making (MCDM) approach for selecting solar plants site and technology: a review. Int J Renew Energy Dev. 2019;8:15–25.

Zayed ME, Zhao J, Li W, Elsheikh AH, Zhao Z, Khalil A, et al. Performance prediction and techno-economic analysis of solar dish/stirling system for electricity generation. Appl Therm Eng. 2020;164:114427.

Firth A, Zhang B, Yang A. Quantification of global waste heat and its environmental effects. Appl Energy. 2019;235:1314–34.

Panayiotou GP, Bianchi G, Georgiou G, Aresti L, Argyrou M, Agathokleous R, et al. Preliminary assessment of waste heat potential in major European industries. Energy Procedia. 2017;123:335–45.

Garcia SI, Garcia RF, Carril JC, Garcia DI. A review of thermodynamic cycles used in low temperature recovery systems over the last two years. Renew Sustain Energy Rev. 2018;81:760–7.

Forman C, Muritala IK, Pardemann R, Meyer B. Estimating the global waste heat potential. Renew Sustain Energy Rev. 2016;57:1568–79.

Hung T-C, Shai TY, Wang SK. A review of organic Rankine cycles (ORCs) for the recovery of low-grade waste heat. Energy. 1997;22:661–7.

Sternlicht B. Waste energy recovery: an excellent investment opportunity. Energy Convers Manag. 1982;22:361–73.

Prigmore D, Barber R. Cooling with the sun’s heat design considerations and test data for a Rankine cycle prototype. Sol Energy. 1975;17:185–92.

Barber RE. Current costs of solar powered organic Rankine cycle engines. Sol Energy. 1978;20:1–6.

Shams Ghoreishi SM, Akbari Vakilabadi M, Bidi M, Khoeini Poorfar A, Sadeghzadeh M, Ahmadi MH, et al. Analysis, economical and technical enhancement of an organic Rankine cycle recovering waste heat from an exhaust gas stream. Energy Sci Eng. 2019;7:230–54.

Naeimi A, Bidi M, Ahmadi MH, Kumar R, Sadeghzadeh M, Nazari MA. Design and exergy analysis of waste heat recovery system and gas engine for power generation in Tehran cement factory. Therm Sci Eng Prog. 2019;9:299–307.

Mohammadi A, Ashouri M, Ahmadi MH, Bidi M, Sadeghzadeh M, Ming T. Thermoeconomic analysis and multiobjective optimization of a combined gas turbine, steam, and organic Rankine cycle. Energy Sci Eng. 2018;6:506–22.

Ashouri M, Ahmadi MH, Pourkiaei SM, Astaraei FR, Ghasempour R, Ming T, et al. Exergy and exergo-economic analysis and optimization of a solar double pressure organic Rankine cycle. Therm Sci Eng Prog. 2018;6:72–86.

Patel B, Desai NB, Kachhwaha SS. Optimization of waste heat based organic Rankine cycle powered cascaded vapor compression-absorption refrigeration system. Energy Convers Manag. 2017;154:576–90.

Noroozian A, Naeimi A, Bidi M, Ahmadi MH. Exergoeconomic comparison and optimization of organic Rankine cycle, trilateral Rankine cycle and transcritical carbon dioxide cycle for heat recovery of low-temperature geothermal water. Proc Inst Mech Eng Part A J Power Energy. 2019;233:1068–84.

Jradi M, Riffat S. Tri-generation systems: energy policies, prime movers, cooling technologies, configurations and operation strategies. Renew Sustain Energy Rev. 2014;32:396–415.

Ghorbani B, Mehrpooya M, Sadeghzadeh M. Developing a tri-generation system of power, heating, and freshwater (for an industrial town) by using solar flat plate collectors, multi-stage desalination unit, and Kalina power generation cycle. Energy Convers Manag. 2018;165:113–26.

Ahmadi MH, Ghazvini M, Sadeghzadeh M, Alhuyi Nazari M, Kumar R, Naeimi A, et al. Solar power technology for electricity generation: a critical review. Energy Sci Eng. 2018;6:340–61.

Ahmadi MH, Sadaghiani MS, Pourfayaz F, Ghazvini M, Mahian O, Mehrpooya M, et al. Energy and exergy analyses of a solid oxide fuel cell-gas turbine-organic rankine cycle power plant with liquefied natural gas as heat sink. Entropy. 2018;20:1–22.

Zhao Y, Liu G, Li L, Yang Q, Tang B, Liu Y. Expansion devices for organic Rankine cycle (ORC) using in low temperature heat recovery: a review. 111944. 2019;199:111944.

Lamfon NJ, Najjar YSH, Akyurt M. Modeling and simulation of combined gas turbine engine and heat pipe system for waste heat recovery and utilization. Energy Convers Manag. 1998;39:81–6.

Carcasci C, Ferraro R, Miliotti E. Thermodynamic analysis of an organic Rankine cycle for waste heat recovery from gas turbines. Energy. 2014;65:91–100.

Mohammadi A, Kasaeian A, Pourfayaz F, Ahmadi MH. Thermodynamic analysis of a combined gas turbine, ORC cycle and absorption refrigeration for a CCHP system. Appl Therm Eng. 2017;111:397–406.

Najjar YSH, Radhwan AM. Cogeneration by combining gas turbine engine with organic Rankine cycle. Heat Recover Syst CHP. 1988;8:211–9.

Clemente S, Micheli D, Reini M, Taccani R. Bottoming organic Rankine cycle for a small scale gas turbine: a comparison of different solutions. Appl Energy. 2013;106:355–64.

Kose O, Koc Y, Yagli H. Performance improvement of the bottoming steam Rankine cycle (SRC) and organic Rankine cycle (ORC) systems for a triple combined system using gas turbine (GT) as topping cycle. Energy Convers Manag. 2020;211:112745.

Ahmadi P, Dincer I, Rosen MA. Exergo-environmental analysis of an integrated organic Rankine cycle for trigeneration. Energy Convers Manag. 2012;64:447–53.

Khaljani M, Saray RK, Bahlouli K. Comprehensive analysis of energy, exergy and exergo-economic of cogeneration of heat and power in a combined gas turbine and organic Rankine cycle. Energy Convers Manag. 2015;97:154–65.

Nami H, Mahmoudi SMS, Nemati A. Exergy, economic and environmental impact assessment and optimization of a novel cogeneration system including a gas turbine, a supercritical CO2 and an organic Rankine cycle (GT-HRSG/SCO2). Appl Therm Eng. 2017;110:1315–30.

Talebizadehsardari P, Ehyaei MA, Ahmadi A, Jamali DH, Shirmohammadi R, Eyvazian A, et al. Energy, exergy, economic, exergoeconomic, and exergoenvironmental (5E) analyses of a triple cycle with carbon capture. J CO2 Util. 2020;41:101258.

Roy D, Samanta S, Ghosh S. Techno-economic and environmental analyses of a biomass based system employing solid oxide fuel cell, externally fired gas turbine and organic Rankine cycle. J Clean Prod. 2019;225:36–57.

Lemort V, Quoilin S, Cuevas C, Lebrun J. Testing and modeling a scroll expander integrated into an Organic Rankine Cycle. Appl Therm Eng. 2009;29:3094–102.

Wang H, Peterson R, Harada K, Miller E, Ingram-Goble R, Fisher L, et al. Performance of a combined organic Rankine cycle and vapor compression cycle for heat activated cooling. Energy. 2011;36:447–58.

Kim KH, Perez-Blanco H. Performance analysis of a combined organic Rankine cycle and vapor compression cycle for power and refrigeration cogeneration. Appl Therm Eng. 2015;91:964–74.

Ebadollahi M, Rostamzadeh H, Seyedmatin P, Ghaebi H, Amidpour M. Thermal and exergetic performance enhancement of basic dual-loop combined cooling and power cycle driven by solar energy. Therm Sci Eng Prog. 2020;18:100556.

Patel B, Desai NB, Kachhwaha SS, Jain V, Hadia N. Thermo-economic analysis of a novel organic Rankine cycle integrated cascaded vapor compression–absorption system. J Clean Prod. 2017;154:26–40.

Javanshir N, Seyed Mahmoudi SM, Rosen MA. Thermodynamic and exergoeconomic analyses of a novel combined cycle comprised of vapor-compression refrigeration and organic rankine cycles. Sustainability. 2019;11:3374.

Tontu M, Sahin B, Bilgili M. Analysis and performance assessment of coal-fired based integrated energy system for multigeneration. Energy Sources Part A Recover Util Environ Eff. 2019;1–19.

Meyer L, Tsatsaronis G, Buchgeister J, Schebek L. Exergoenvironmental analysis for evaluation of the environmental impact of energy conversion systems. Energy. 2009;34:75–89.

Petrakopoulou F, Boyano A, Cabrera M, Tsatsaronis G. Exergoeconomic and exergoenvironmental analyses of a combined cycle power plant with chemical looping technology. Int J Greenh Gas Control. 2011;5:475–82.

Aghbashlo M, Hosseinpour S, Tabatabaei M, Rastegari H, Ghaziaskar HS. Multi-objective exergoeconomic and exergoenvironmental optimization of continuous synthesis of solketal through glycerol ketalization with acetone in the presence of ethanol as co-solvent. Renew Energy. 2019;130:735–48.

Ghorbani S, Khoshgoftar-Manesh MH, Nourpour M, Blanco-Marigorta AM. Exergoeconomic and exergoenvironmental analyses of an integrated SOFC-GT-ORC hybrid system. Energy. 2020;206:118151.

Hadelu LM, Boyaghchi FA. Exergoeconomic and exergoenvironmental analyses and optimization of different ejector based two stage expander-organic flash cycles fuelled by solar energy. Energy Convers Manag. 2020;216:112943.

Abdollahpour A, Ghasempour R, Kasaeian A, Ahmadi MH. Exergoeconomic analysis and optimization of a transcritical CO 2 power cycle driven by solar energy based on nanofluid with liquefied natural gas as its heat sink. J Therm Anal Calorim. 2020;139:451–73.

Javadi MA, Ahmadi MH, Khalaji M. Exergetic, economic, and environmental analyses of combined cooling and power plants with parabolic solar collector. Environ Prog Sustain Energy. 2020;39:e13322.

Nikzad A, Chahartaghi M, Ahmadi MH. Technical, economic, and environmental modeling of solar water pump for irrigation of rice in Mazandaran province in Iran: a case study. J Clean Prod. 2019;239:118007.

Ahmadi MH, Dehghani Madvar M, Sadeghzadeh M, Rezaei MH, Herrera M, Shamshirband S. Current status investigation and predicting carbon dioxide emission in Latin American countries by connectionist models. Energies. 2019;12:1916.

Odum HT. Environmental accounting: emergy and environmental decision making. Hoboken, NJ: Wiley; 1996.

Hau JL, Bakshi BR. Promise and problems of emergy analysis. Ecol Modell. 2004;178:215–25.

Aghbashlo M, Rosen MA. Consolidating exergoeconomic and exergoenvironmental analyses using the emergy concept for better understanding energy conversion systems. J Clean Prod. 2018;172:696–708.

Rafat E, Babaelahi M, Mofidipour E. Sustainability analysis of low temperature solar-driven Kalina power plant using emergy concept. Int J Thermodyn. 2019;22:118–26.

Alibaba M, Pourdarbani R, Manesh MHK, Ochoa GV, Forero JD. Thermodynamic, exergo-economic and exergo-environmental analysis of hybrid geothermal-solar power plant based on ORC cycle using emergy concept. Heliyon. 2020;6:e03758.

Babaelahi M, Rafat E, Mofidipour E. Emergy-based economic and environmental analysis and multi-objective optimization of a two-cascade solar gas turbine power plant. Sustain Prod Consum. 2019;20:165–77.

Mahmoudan A, Samadof P, Sadeghzadeh M, Jalili M, Sharifpur M, Kumar R. Thermodynamic and exergoeconomic analyses and performance assessment of a new configuration of a combined cooling and power generation system based on ORC–VCR. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-10230-y.

Bakshi BR. A thermodynamic framework for ecologically conscious process systems engineering. Comput Chem Eng. 2000;24:1767–73.

Odum HT. Environment, power, and society for the twenty-first century: the hierarchy of energy. New York: Columbia University Press; 2007.

Lazzaretto A, Tsatsaronis G. SPECO: a systematic and general methodology for calculating efficiencies and costs in thermal systems. Energy. 2006;31:1257–89.

Lourenço AB. Bi-objective optimization of a combined cycle power plant with economic and life cycle assessment considerations. Process Integr Optim Sustain. 2020;4:67–79.

Cavalcanti EJC. Exergoeconomic and exergoenvironmental analyses of an integrated solar combined cycle system. Renew Sustain Energy Rev. 2017;67:507–19.

Usman M, Imran M, Yang Y, Park B-S. Impact of organic Rankine cycle system installation on light duty vehicle considering both positive and negative aspects. Energy Convers Manag. 2016;112:382–94.

BITZER LTD. Semi-hermetic Recip. Compressors (2-stage). BITZER. [cited 2014 May 1]. https://www.bitzer.de/shared_media/documentation/kp-150-5.pdf.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mahmoudan, A., Samadof, P., Kumar, R. et al. Emergy-based exergoeconomic and exergoenvironmental evaluation of a combined power and cooling system based on ORC-VCR. J Therm Anal Calorim 145, 1353–1372 (2021). https://doi.org/10.1007/s10973-020-10422-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10422-6