Abstract

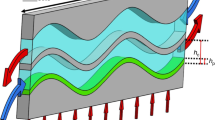

In this paper, nanofluid forced convective heat transfer through an open-cell metal foam heatsink under a uniform heat flux, numerically has been investigated. A uniform magnetic field has been applied to the nanofluid flow. For the momentum equation, Darcy–Brinkman model and, for the energy equation, two-equation model under the condition of fully developed from the thermal and hydrodynamical standpoints have been used. In recent study, by utilizing a numerical method, an attempt was made to avoid a complete and complex CFD approach. To validate the results, the dimensionless parameters such as non-dimensional velocity and temperature, pressure gradient and Nusselt number have been compared with previous researches and a good agreement appeared. Eventually, the effects of different dimensionless parameters such as porosity, Hartman number, nanofluid volume fraction, Reynolds number, thermal conductivity ratio and pore density on the hydrodynamical and thermal characteristics of heatsink have been investigated. The outcomes show that the rise of pore density and Hartman number and the decline of the porosity will enhance the thermal performance; however, it also will reinforce the resistance to the flow through the porous media. Focusing on results illustrates that Nusselt number variation for increasing porosity from 0.85 to 0.95 at the minimum and maximum of the pore density are \(\left( {\Delta {\text{Nu}}_{{\left(\upvarepsilon \right)}} } \right)_{{\upomega = 10}} = - 331.7\) and \(\left( {\Delta {\text{Nu}}_{{\left(\upvarepsilon \right)}} } \right)_{\omega = 60} = - 367.8\), and these values for friction factor are equal to \(\left( {\Delta f_{{\left(\upvarepsilon \right)}} } \right)_{{\upomega = 10}} = - 22.3\) and \(\left( {\Delta f_{{\left(\upvarepsilon \right)}} } \right)_{{\upomega = 60}} = - 793\), respectively. On the other hand, increasing Hartman number from 0 to 100 would change the Nusselt number and friction factor as \(\left( {\Delta {\text{Nu}}_{{\left( {\text{Ha}} \right)}} } \right)_{{\upomega = 10}} = 9.4\), \(\left( {\Delta {\text{Nu}}_{{\left( {\text{Ha}} \right)}} } \right)_{{\upomega = 60}} = 0.2\), \(\left( {\Delta f_{{\left( {\text{Ha}} \right)}} } \right)_{{\upomega = 10}} = 213\), and \(\left( {\Delta f_{{\left( {\text{Ha}} \right)}} } \right)_{{\upomega = 60}} = 211\), respectively. The amount of Hartman and Reynolds numbers effects on the heat transfer rate depends on the pore density. In other words, when the pore density becomes saturated, the effects of these parameters decrease. In addition, the use of nanofluid will improve the heatsink thermal performance.

Similar content being viewed by others

Abbreviations

- \(A_{\text{sf}}\) :

-

Specific surface area (m−1)

- B :

-

Magnetic field (T)

- Bi:

-

Biot number

- \(c_{\text{p}}\) :

-

Specific heat (J kg−1 K−1)

- Da:

-

Darcy number

- \(d_{\text{f}}\) :

-

Fiber diameter (m)

- \(d_{\text{p}}\) :

-

Pore diameter (m)

- f :

-

Friction factor

- H :

-

Half height of heatsink (m)

- \(h_{\text{sf}}\) :

-

Interstitial heat transfer coefficient (W m−2 K−1)

- Ha:

-

Hartmann number

- k :

-

Thermal conductivity (W m−1K−1)

- K :

-

Permeability (m2)

- L :

-

Length of heatsink (m)

- p :

-

Pressure (Pa)

- P :

-

Dimensionless pressure

- Pr:

-

Prandtl number

- \(q^{\prime\prime}\) :

-

Heat flux (W m−2)

- Re:

-

Reynolds number

- T :

-

Temperature (K)

- \(T_{\text{in}}\) :

-

Inlet temperature (K)

- \(T_{\text{w}}\) :

-

Wall temperature (K)

- u, v :

-

x-, y-direction velocity (m s−1)

- u m :

-

Average inlet velocity (m s−1)

- U :

-

Dimensionless velocity

- x, y :

-

Cartesian coordinates (m)

- Y :

-

Dimensionless y-coordinate

- \(\gamma\) :

-

Magnetic angle (rad)

- \(\varepsilon\) :

-

Porosity

- \(\omega\) :

-

Pore density, PPI (pores per in.)

- \(\sigma\) :

-

Electrical conductivity \(\left( {\Omega {\text{m}}} \right)^{ - 1}\)

- \(\varphi\) :

-

Nanoparticle volume fraction

- \(\mu\) :

-

Dynamic viscosity (Pa s)

- \(\theta\) :

-

Dimensionless temperature

- \(\rho\) :

-

Density (kg m−3)

- b:

-

Bulk

- bf:

-

Base fluid

- e:

-

Effective

- f:

-

Fluid phase

- nf:

-

Nanofluid

- np:

-

Nanoparticle

- s:

-

Solid phase

References

Siavashi M, Joibary SMM. Numerical performance analysis of a counter-flow double-pipe heat exchanger with using nanofluid and both sides partly filled with porous media. J Therm Anal Calorim. 2019;135:1595–610.

Izadi A, Siavashi M, Rasam H, Xiong Q. MHD enhanced nanofluid mediated heat transfer in porous metal for CPU cooling. Appl Therm Eng. 2020;168:114843.

Joibary SMM, Siavashi M. Effect of Reynolds asymmetry and use of porous media in the counterflow double-pipe heat exchanger for passive heat transfer enhancement. J Therm Anal Calorim. 2019;1–15.

Pourrahmani H, Moghimi M, Siavashi M, Shirbani M. Sensitivity analysis and performance evaluation of the PEMFC using wave-like porous ribs. Appl Therm Eng. 2019;150:433–44.

Moosaie A, Shekouhi N, Nouri N, Manhart M. An algebraic closure model for the DNS of turbulent drag reduction by Brownian microfiber additives in a channel flow. J Non-Newton Fluid Mech. 2015;226:60–6.

Norouzi AM, Siavashi M, Soheili AR, Oskouei MK. Experimental investigation of effects of grain size, inlet pressure and flow rate of air and argon on pressure drop through a packed bed of granular activated carbon. Int Commun Heat Mass Transf. 2018;96:20–6.

Kim SY, Paek JW, Kang BH. Thermal performance of aluminum-foam heat sinks by forced air cooling. IEEE Trans Compon Packag Technol. 2003;26:262–7.

Wang T, Luan W, Liu T, Tu S-T, Yan J. Performance enhancement of thermoelectric waste heat recovery system by using metal foam inserts. Energy Convers Manag. 2016;124:13–9.

Dukhan N, Chen K-C. Heat transfer measurements in metal foam subjected to constant heat flux. Exp Therm Fluid Sci. 2007;32:624–31.

Wan Z, Guo G, Su K, Tu Z, Liu W. Experimental analysis of flow and heat transfer in a miniature porous heat sink for high heat flux application. Int J Heat Mass Transf. 2012;55:4437–41.

Hajipour M, Dehkordi AM. Mixed-convection flow of Al2O3–H2O nanofluid in a channel partially filled with porous metal foam: experimental and numerical study. Exp Therm Fluid Sci. 2014;53:49–56.

Sopian K, Daud WRW, Othman MY, Yatim B. Thermal performance of the double-pass solar collector with and without porous media. Renew Energy. 1999;18:557–64.

Rabbani P, Hamzehpour A, Ashjaee M, Najafi M, Houshfar E. Experimental investigation on heat transfer of MgO nanofluid in tubes partially filled with metal foam. Powder Technol. 2019;354:734–42.

Ali HM. Experimental study on the thermal behavior of RT-35HC paraffin within copper and Iron-Nickel open cell foams: Energy storage for thermal management of electronics. Int J Heat Mass Transf. 2020;146:118852.

Kim DY, Nematollahi O, Kim KC. Flow-pattern-based experimental analysis of convective boiling heat transfer in a rectangular channel filled with open-cell metallic random porous media. Int J Heat Mass Transf. 2019;142:118402.

Awin Y, Dukhan N. Experimental performance assessment of metal-foam flow fields for proton exchange membrane fuel cells. Appl Energy. 2019;252:113458.

Siavashi M, Ghasemi K, Yousofvand R, Derakhshan S. Computational analysis of SWCNH nanofluid-based direct absorption solar collector with a metal sheet. Sol Energy. 2018;170:252–62.

Chuan L, Wang X-D, Wang T-H, Yan W-M. Fluid flow and heat transfer in microchannel heat sink based on porous fin design concept. Int Commun Heat Mass Transf. 2015;65:52–7.

Rong F, Shi B, Cui X. Lattice Boltzmann simulation of heat and fluid flow in 3D cylindrical heat exchanger with porous blocks. Appl Math Comput. 2016;276:367–78.

Xu Z, Gong Q. Numerical investigation on forced convection of tubes partially filled with composite metal foams under local thermal non-equilibrium condition. Int J Therm Sci. 2018;133:1–12.

Bovand M, Rashidi S, Esfahani JA. Heat transfer enhancement and pressure drop penalty in porous solar heaters: numerical simulations. Sol Energy. 2016;123:145–59.

Xu H, Gong L, Huang S, Xu M. Flow and heat transfer characteristics of nanofluid flowing through metal foams. Int J Heat Mass Transf. 2015;83:399–407.

Choi SU, Eastman JA. Enhancing thermal conductivity of fluids with nanoparticles. Lemont, IL: Argonne National Laboratory; 1995.

Norouzi AM, Siavashi M, Oskouei MK. Efficiency enhancement of the parabolic trough solar collector using the rotating absorber tube and nanoparticles. Renew Energy. 2020;145:569–84.

Siavashi M, Iranmehr S. Using sharp wedge-shaped porous media in front and wake regions of external nanofluid flow over a bundle of cylinders. Int J Numer Methods Heat Fluid Flow. 2019;29(10):3730–55.

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, et al. Recent advances in modeling and simulation of nanofluid flows—part I: fundamentals and theory. Phys Rep. 2019;790:1–48.

Mohebbi R, Rasam H, Numerical simulation of conjugate heat transfer in a square cavity consisting the conducting partitions using the lattice Boltzmann method. Phys A: Stat Mech Appl. 2019;123050.

Barnoon P, Toghraie D. Numerical investigation of laminar flow and heat transfer of non-Newtonian nanofluid within a porous medium. Powder Technol. 2018;325:78–91.

Izadi A, Siavashi M, Xiong Q. Impingement jet hydrogen, air and CuH2O nanofluid cooling of a hot surface covered by porous media with non-uniform input jet velocity. Int J Hydrogen Energy. 2019;44:15933–48.

Siavashi M, Rasam H, Izadi A. Similarity solution of air and nanofluid impingement cooling of a cylindrical porous heat sink. J Therm Anal Calorim. 2019;135:1399–415.

Ting TW, Hung YM, Guo N. Viscous dissipative nanofluid convection in asymmetrically heated porous microchannels with solid-phase heat generation. Int Commun Heat Mass Transf. 2015;68:236–47.

Tong Y, Lee H, Kang W, Cho H. Energy and exergy comparison of a flat-plate solar collector using water, Al2O3 nanofluid, and CuO nanofluid. Appl Therm Eng. 2019;159:113959.

Xu H, Xing Z. The lattice Boltzmann modeling on the nanofluid natural convective transport in a cavity filled with a porous foam. Int Commun Heat Mass Transf. 2017;89:73–82.

Emami RY, Siavashi M, Moghaddam GS. The effect of inclination angle and hot wall configuration on Cu–water nanofluid natural convection inside a porous square cavity. Adv Powder Technol. 2018;29:519–36.

Sheikholeslami M, Ganji D. Heat transfer of Cu–water nanofluid flow between parallel plates. Powder Technol. 2013;235:873–9.

Xu HJ, Xing ZB, Wang F, Cheng Z. Review on heat conduction, heat convection, thermal radiation and phase change heat transfer of nanofluids in porous media: fundamentals and applications. Chem Eng Sci. 2019;195:462–83.

Khanafer K, Vafai K. Applications of nanofluids in porous medium. J Therm Anal Calorim. 2019;135:1479–92.

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, et al. Recent advances in modeling and simulation of nanofluid flows—part II: applications. Phys Rep. 2018;790:1–48.

Kabeel A, El-Said EM, Dafea S. A review of magnetic field effects on flow and heat transfer in liquids: present status and future potential for studies and applications. Renew Sustain Energy Rev. 2015;45:830–7.

Jahanbakhshi A, Nadooshan AA, Bayareh M. Magnetic field effects on natural convection flow of a non-Newtonian fluid in an L-shaped enclosure. J Therm Anal Calorim. 2018;133:1407–16.

Shahriari A, Ashorynejad HR, Pop I. Entropy generation of MHD nanofluid inside an inclined wavy cavity by lattice Boltzmann method. J Therm Anal Calorim. 2019;135:283–303.

Ma Y, Mohebbi R, Rashidi M, Yang Z. MHD forced convection of MWCNT–Fe3O4/water hybrid nanofluid in a partially heated τ-shaped channel using LBM. J Therm Anal Calorim. 2019;136:1723–35.

Selimefendigil F, Chamkha AJ. Magnetohydrodynamics mixed convection in a power law nanofluid-filled triangular cavity with an opening using Tiwari and Das’ nanofluid model. J Therm Anal Calorim. 2019;135:419–36.

Sheikholeslami M, Rokni HB. Simulation of nanofluid heat transfer in presence of magnetic field: a review. Int J Heat Mass Transf. 2017;115:1203–33.

Xu H, Qu Z, Tao W. Thermal transport analysis in parallel-plate channel filled with open-celled metallic foams. Int Commun Heat Mass Transf. 2011;38:868–73.

Mahmoudi Y, Maerefat M. Analytical investigation of heat transfer enhancement in a channel partially filled with a porous material under local thermal non-equilibrium condition. Int J Therm Sci. 2011;50:2386–401.

Xu H, Gong L, Huang S, Xu M. Non-equilibrium heat transfer in metal-foam solar collector with no-slip boundary condition. Int J Heat Mass Transf. 2014;76:357–65.

Sivaraj C, Sheremet MA. MHD natural convection in an inclined square porous cavity with a heat conducting solid block. J Magn Magn Mater. 2017;426:351–60.

Shampine LF, Kierzenka J, Reichelt MW. Solving boundary value problems for ordinary differential equations in MATLAB with bvp4c. Tutor Notes. 2000;2000:1–27.

Lee D-Y, Vafai K. Analytical characterization and conceptual assessment of solid and fluid temperature differentials in porous media. Int J Heat Mass Transf. 1999;42:423–35.

Lu W, Zhao C, Tassou S. Thermal analysis on metal-foam filled heat exchangers. Part I: metal-foam filled pipes. Int J Heat Mass Transf. 2006;49:2751–61.

Xu Z, Qin J, Zhou X, Xu H. Forced convective heat transfer of tubes sintered with partially-filled gradient metal foams (GMFs) considering local thermal non-equilibrium effect. Appl Therm Eng. 2018;137:101–11.

Boomsma K, Poulikakos D. On the effective thermal conductivity of a three-dimensionally structured fluid-saturated metal foam. Int J Heat Mass Transf. 2001;44:827–36.

Qu Z, Xu H, Tao W. Fully developed forced convective heat transfer in an annulus partially filled with metallic foams: an analytical solution. Int J Heat Mass Transf. 2012;55:7508–19.

Begum AS, Nithyadevi N, Öztop HF, Al-Salem K. Numerical simulation of MHD mixed convection in a nanofluid filled non-Darcy porous enclosure. Int J Mech Sci. 2017;130:154–66.

Hussain S, Mehmood K, Sagheer M. MHD mixed convection and entropy generation of water–alumina nanofluid flow in a double lid driven cavity with discrete heating. J Magn Magn Mater. 2016;419:140–55.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Izadi, A., Abdipour, M. & Rasam, H. MHD forced convection of nanofluid flow in an open-cell metal foam heatsink under LTNE conditions. J Therm Anal Calorim 141, 1847–1857 (2020). https://doi.org/10.1007/s10973-020-09478-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09478-1