Abstract

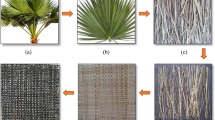

Bamboo-/kenaf-reinforced epoxy hybrid composites were prepared by hand layup method. The aim of this study is to look into the hybridization effect of bamboo and kenaf fibers at different ratios on thermal and thermo-oxidative (TOD) stabilities of hybrid composites. Three types of hybrid composites were fabricated with different mass ratios of bamboo fiber mat (B) to kenaf fiber mat (K), namely B/K 70:30, B/K 50:50 and B/K 70:30 while maintaining total fiber loading of 40% by mass. The thermal stability and thermo-oxidative (TOD) stability were analyzed by thermogravimetric analyzer. Differential scanning calorimetry (DSC) was used to investigate the oxidation onset temperature (OOT) of all the composites. The results reveal that bamboo composite shows higher thermal stability than kenaf composite in both inert and oxidative atmospheres. An increase in bamboo fibers mass ratio in the hybrid composite improved the thermal and TOD stability. The thermal and TOD stabilities of the hybrid composites follow the sequence of B/K 70: 30 > B/K 50:50 > B/K 30:70. Pure epoxy composite recorded the highest OOT at 197.50 °C. The results show that the addition of natural fiber in the epoxy matrix has significantly reduced the OOT compared to the pure epoxy. Data obtained from this work will help us to fabricate a sustainable and biodegradable component for automotive or building materials.

Similar content being viewed by others

References

Kiruthika AV. A review on physico-mechanical properties of bast fibre reinforced polymer composites. J Build Eng. 2017;9:91–9.

Anuar H, Zuraida A. Improvement in mechanical properties of reinforced thermoplastic elastomer composite with kenaf bast fibre. Compos Part B Eng. 2011;42:462–5.

Atiqah A, Maleque MA, Jawaid M, Iqbal M. Development of kenaf-glass reinforced unsaturated polyester hybrid composite for structural applications. Compos Part B Eng. 2014;56:68–73.

Yahaya R, Sapuan SM, Jawaid M, Leman Z, Zainudin ES. Effect of layering sequence and chemical treatment on the mechanical properties of woven kenaf–aramid hybrid laminated composites. Mater Des. 2015;67:173–9.

Azwa ZN, Yousif BF. Characteristics of kenaf fibre/epoxy composites subjected to thermal degradation. Polym Degrad Stab. 2013;98:2752–9.

Mahdavi M, Clouston PL, Arwade SR. A low-technology approach toward fabrication of laminated bamboo lumber. Constr Build Mater. 2012;29:257–62.

Abdul Khalil HPS, Bhat IUH, Jawaid M, Zaidon A, Hermawan D, Hadi YS. Bamboo fibre reinforced biocomposites: a review. Mater Des. 2012;42:353–68.

Bahari SA, Grigsby WJ, Krause A. Flexural properties of PVC/bamboo composites under static and dynamic-thermal conditions: effects of composition and water absorption. Int J Polym Sci. 2017;2017:1–8.

Shanmugam D, Thiruchitrambalam M. Static and dynamic mechanical properties of alkali treated unidirectional continuous palmyra palm leaf stalk fiber/jute fiber reinforced hybrid polyester composites. Mater Des. 2013;50:533–42.

Hariharan ABA, Abdul Khalil HPS. Lignocellulose-based hybrid bilayer laminate composite: part I—studies on tensile and impact behavior of oil palm fiber–glass fiber–reinforced epoxy resin. J Compos Mater. 2005;39:663–84.

Abdul Khalil HPS, Kang CW, Khairul A, Ridzuan R, Adawi TO. The effect of different laminations on mechanical and physical properties of hybrid composites. J Reinf Plast Compos. 2009;28:1123–37.

Thiruchitrambalam M, Athijayamani A, Sathiyamurthy S, Thaheer ASA. A review on the natural fiber-reinforced polymer composites for the development of roselle fiber–reinforced polyester composite. J Nat Fibers. 2010;7:307–23.

Maslinda AB, Abdul Majid MS, Ridzuan MJM, Afendi M, Gibson AG. Effect of water absorption on the mechanical properties of hybrid interwoven cellulosic–cellulosic fibre reinforced epoxy composites. Compos Struct. 2017;167:227–37.

Yusoff RB, Takagi H, Nakagaito AN. Tensile and flexural properties of polylactic acid-based hybrid green composites reinforced by kenaf, bamboo and coir fibers. Ind Crops Prod. 2016;94:562–73.

Saw SK, Datta C. Thermomechanical properties of jute/baggase hybrid fibre reinforced epoxy thermoset composites. Bioresources. 2009;4:1455–75.

Jawaid M, Abdul Khalil HPS. Effect of layering pattern on the dynamic mechanical properties and thermal degradation of oil palm–jute fibers reinforced epoxy hybrid composite. Bioresources. 2011;6:2309–22.

Shah AUM, Sultan MTH, Cardona F, Jawaid M, Talib ARA, Yidris N. Thermal analysis of bamboo fibre and its composites. Bioresources. 2017;12:2394–406.

Singh TJ, Rajini N, Karthikeyan S, Thiruchitrambalam M, Venkateshwaren N. Mechanical properties of banana/kenaf fiber-reinforced hybrid polyester composites: effect of woven fabric and random orientation. Mater Des Part A. 2015;66:246–57.

Wang W, Sain M, Cooper PA. Hygrothermal weathering of rice hull/HDPE composites under extreme climatic conditions. Polym Degrad Stab. 2005;90:540–5.

Lisa G, Hamciuc C, Hamciuc E, Tudorachi N. Thermal and thermo-oxidative stability and probable degradation mechanism of some polyetherimides. J Anal Appl Pyrolysis. 2016;118:144–54.

Monteiro SN, Calado V, Rodriguez RJS, Margem FM. Thermogravimetric behavior of natural fibers reinforced polymer composites—an overview. Mater Sci Eng A. 2012;557:17–28.

Stevulova N, Estokova A, Cigasova J, Schwarzova I, Kacik F, Geffert A. Thermal degradation of natural and treated hemp hurds under air and nitrogen atmosphere. J Therm Anal Calorim. 2017;128:1649–60.

Borysiak S. The thermo-oxidative stability and flammability of wood/polypropylene composites. J Therm Anal Calorim. 2015;119:1955–62.

Chee SS, Jawaid M, Sultan MTH. Thermal stability and dynamic mechanical properties of kenaf/bamboo fibre reinforced epoxy composites. Bioresources. 2017;12:7118–32.

Ishak MR, Sapuan SM, Leman Z, Rahman MZA, Anwar UMK. Characterization of sugar palm (Arenga pinnata) fibres. J Therm Anal Calorim. 2012;109:981–9.

Yang H, Yan R, Chen H, Lee DH, Zheng C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel. 2007;86:1781–8.

Vanholme R, Demedts B, Morreel K, Ralph J, Boerjan W. Lignin biosynthesis and structure. Plant Physiol. 2010;153:895–905.

Collard FX, Blin J. A review on pyrolysis of biomass constituents: mechanisms and composition of the products obtained from the conversion of cellulose, hemicelluloses and lignin. Renew Sustain Energy Rev. 2014;38:594–608.

Abdul Khalil HPS, Suraya NL. Anhydride modification of cultivated kenaf bast fibers: morphological, spectroscopic and thermal studied. Bioresources. 2011;6:1122–35.

Zakikhani P, Zahari R, Hameed Sultan MT, Abang Abdul Majid DL. Thermal degradation of four bamboo species. Bioresources. 2015;11:414–25.

Nadlene R, Sapuan SM, Jawaid M, Ishak MR, Yusriah L. Material characterization of roselle fibre (Hibiscus sabdariffa L.) as potential reinforcement material for polymer composites. Fibres Text East Eur. 2015;23:23–30.

Pandey SN, Day A, Mathew MD. Thermal analysis of chemically treated jute fibers. Text Res J. 1993;63:143–50.

Martin AR, Martins MA, Da Silva ORRF, Mattoso LHC. Studies on the thermal properties of sisal fiber and its constituents. Thermochim Acta. 2010;506:14–9.

Rachini A, Le Troedec M, Peyratout C, Smith A. Comparison of the thermal degradation of natural, alkali-treated and silane-treated hemp fibers under air and an inert atmosphere. J Appl Polym Sci. 2009;112:226–34.

Zhang X, Wu Y, Wen H, Hu G, Yang Z, Tao J. The influence of oxygen on thermal decomposition characteristics of epoxy resins cured by anhydride. Polym Degrad Stab. 2018;156:125–31.

Beyler CL, Hirschler MM. Thermal decomposition of polymers, vol. 2., SFPE handbook of fire protection engineeringAmsterdam: Elsevier; 2002. p. 10.

Kačík F, Šmíra P, Kačíková D, Veľková V, Nasswettrová A, Vacek V. Chemical alterations of pine wood saccharides during heat sterilisation. Carbohydr Polym. 2015;117:681–6.

Dorez G, Ferry L, Sonnier R, Taguet A, Lopez-Cuesta JM. Effect of cellulose, hemicellulose and lignin contents on pyrolysis and combustion of natural fibers. J Anal Appl Pyrolysis. 2014;107:323–31.

Ozcelik O, Aktas L, Altan MC. Thermo-oxidative degradation of graphite/epoxy composite laminates: modeling and long-term predictions. Express Polym Lett. 2009;3:797–803.

Colin X, Verdu J. Thermal ageing and lifetime prediction for organic matrix composites. Plast Rubber Compos. 2003;32:349–56.

Kholodovych V, Welsh WJ. Thermal-oxidative stability and degradation of polymers. In: Mark James E, editor. Physical properties polymer handbook. Berlin: Springer; 2007. p. 927–38.

Demirkir C, Aydin I, Colak S, Ozturk H. Effects of plasma surface treatment on bending strength and modulus of elasticity of beech and poplar plywood. Maderas Cienc y Tecnol. 2017;19:195–202.

Razali N, Salit MS, Jawaid M, Ishak MR, Lazim Y. A study on chemical composition, physical, tensile, morphological, and thermal properties of roselle fibre: effect of fibre maturity. Bioresources. 2015;10:1803–23.

Acknowledgements

The authors are thankful to Universiti Putra Malaysia for supporting this research through Putra Grant No. 9490601. The authors also extend their appreciation to International Scientific Partnership Program ISPP at King Saud University for funding this research through ISPP-011.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chee, S.S., Jawaid, M., Sultan, M.T.H. et al. Evaluation of the hybridization effect on the thermal and thermo-oxidative stability of bamboo/kenaf/epoxy hybrid composites. J Therm Anal Calorim 137, 55–63 (2019). https://doi.org/10.1007/s10973-018-7918-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7918-z